Up, up and away

Up, up and away

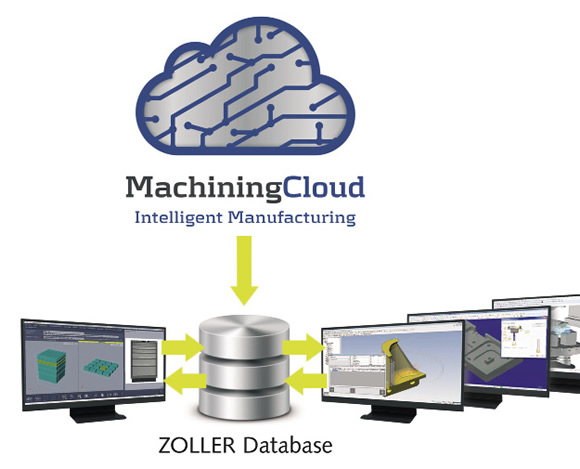

An intelligent manufacturing application.

Even when end users know what cutting tool assembly they're looking for, finding the various elements in paper and Web-based catalogs can be time-consuming. It typically involves locating a tool with the correct diameter and adapter, selecting the appropriate inserts with the required corner radius and other features and ensuring it's suitable for cutting the specified workpiece material.

In a test using catalogs, assembling a tooling package took 4 hours, noted Michael Taesch, project manager for Machining Cloud GmbH, which offers an "intelligent" cloud-based machining application. He added that the same task took about 10 minutes using the application. "It's like an electronic catalog but smarter," he said. "This is where the time savings comes from. You don't have to try to figure out where the data is. It's right in front of you."

Taesch pointed out that, in addition to the selector section that helps locate tools using two "smart" filters, the machining application includes a tool adviser to help determine the proper machining parameters and a configurator to assist combining the cutter with the correct adapter and inserts. The tool adviser is available for milling and holemaking applications, with an adviser for turning scheduled for release in the near future.

Like all cloud-based applications, Machining Cloud uses a network of remote servers hosted on the Internet to store, manage and process data. This provides vast amounts of readily accessible information, whenever and wherever it's needed.

Courtesy of Zoller

Machining Cloud can provide CAM systems with complete 2-D and 3-D tool data, as well as article characteristics.

Kennametal Inc., Latrobe, Pa., is the first toolmaker to publish its standard catalog, which contains about 55,000 products, on the application. "They publish their data under the application name NOVO—process knowledge delivered via Machining Cloud," Taesch said, adding that other leading cutting tool manufacturers plan to participate. "We are working on integrating their data."

Software developer Zoller Inc., Ann Arbor, Mich., has also partnered with Machining Cloud, making its array of tool management software available to manufacturers. "With all of its products, Zoller contributes to more efficiency in the manufacturing process," said CEO Alexander Zoller. "We give great value to forward-thinking partnerships for innovative products that create real value to users, such as Machining Cloud."

According to Machining Cloud, because information provided by the application can be directly connected to CAM, machining simulation and tool management software, the application data is automatically imported and readily accessible to generate shop-floor documentation and tool lists. The application supports Microsoft Windows 7 and 8, as well as iPad and Windows and Android tablets.

End users can download the application free of charge. "They don't need to register with us unless they want to create a job, which gives them a little more information and functionality," Taesch explained. He noted the company plans to soon add e-commerce capability.

For more information about Machining Cloud GmbH, Stans, Switzerland, visit www.machiningcloud.com or e-mail [email protected]. CTE