Grinding sensitive parts

Grinding sensitive parts

Our supplier in Asia is grinding hardened-steel parts and sending them to us for final processing. Some of them are cracking, so we're going to visit the supplier. What should we be looking for?

Dear Doc: Our supplier in Asia is grinding hardened-steel parts and sending them to us for final processing. Some of them are cracking, so we're going to visit the supplier. What should we be looking for?

The Doc Replies: Typically, there are two possible causes for cracks. The first is that grinding temperatures are too high, causing residual tensile stresses, rehardening phase transformation or both. This can lead to immediate cracking or cracking when the part is in the field. To confirm, check ground parts for white layer via sectioning and nital-etching, as well as residual tensile stresses via X-ray diffraction. To stop the cracking, lower the grinding temperatures with sharper dressing or use better grinding parameters.

The second possibility is that the workpiece material was "messed up" before it was ground. This is where the solution can get tricky. The material, prior to heat treatment, may contain flaws, such as pores, cracks and inclusions.

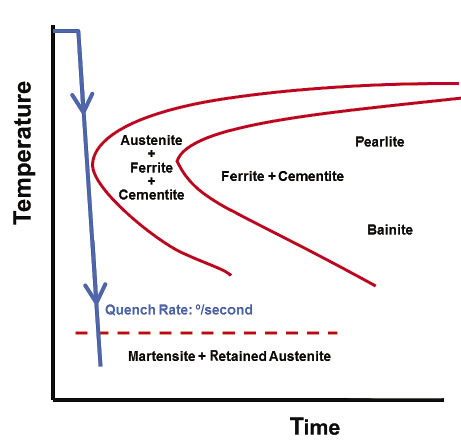

Heat treatment can also cause material to become "sensitive" to cracking, even when grinding temperatures are low. Bad heat treatment often occurs when tempering times are too short, temperatures are not low enough between tempers or when quenching occurs too slowly. This results in strange phases in the material, such as bainite.

One cause of workpiece sensitivity with steel parts is a quench rate that's too low during heat treatment, resulting in unwanted phases, such as bainite, pearlite or ferrite. Illustration courtesy J. Badger.

Before visiting the supplier, pray to the grinding gods that it's high grinding temperatures causing the cracking, because this can be readily solved. If it's material sensitivity, you're in for an adventure. Projects investigating cracking because of material sensitivity can take months to resolve and still yield ambiguous results.

A typical scenario: Parts from your supplier are cracking, so you visit and see that they are getting rehardening burn during grinding. You fix the grinding problem, and the rehardening burn goes away. You go home, but parts occasionally continue to crack. So you go back and see the grinding is still OK—at least during your visit. This time, though, you bring a metallurgist, who examines the supplier's heat-treatment practices and says they look good—at least during your visit.

Back at your shop, parts occasionally continue to crack, and the metallurgist analyzes a part with cracks, but sees good heat treatment and good grinding. He looks deeper and determines the material had become embrittled before heat treatment. He then visits the material supplier. A year later the investigation continues. If you face this scenario, find a good metallurgist, find a knowledgeable grinder and find some patience.