Integrating automated nesting

Integrating automated nesting

The Get With The Program column in the July 2014 issue of Cutting Tool Engineering magazine delves into integrating automated nesting into production work flows.

Traditionally, a CAD/CAM nesting system has been considered an NC pro-gramming tool, where 2D models of components generated in CAD software are used to develop G code to drive CNC machines. In today's manufacturing en-vironment, nesting software as part of a CAM package plays an increasingly im-portant role in maximizing efficiency and productivity.

As with other "computer-aided" tech-nologies, CAM systems do not eliminate the need for skilled professionals, such as manufacturing engineers, NC program-mers and machinists. CAM leverages the value of these skilled workers through ad-vanced productivity tools while helping to build the skills of new professionals through the use of visualization, simu-lation and optimization tools.

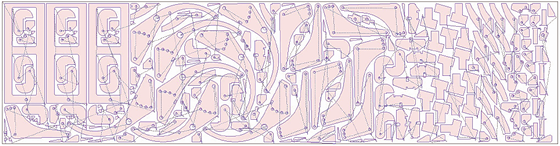

High-end nesting software operates on a desktop PC and, using CAM tech-nology, can streamline the work flow of machining operations. This begins with the automated importation of or-ders and parts, including their CAD ge-ometry, from a business database to a system that tracks and controls plate inventory management, including au-tomated nesting and NC program gener-ation for a variety of tools and machines. (Plate inventory management keeps track of the plates, or workpieces, in stock, their use and geometry when changed by a nest, and tracks what parts were cut from which plate.)

All images courtesy ESAB Welding & Cutting Products

Using CAM technology, nesting software can streamline production workflow.

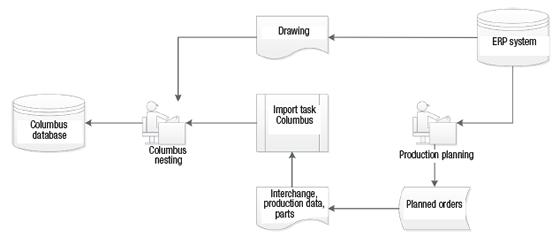

Integration of the nesting software into existing enterprise resource plan-ning systems is key, because it saves a significant amount of production time. The part and order information in the ERP system is necessary for work preparation. But how is this data trans-ferred to the nesting system? Most nest-ing systems can automatically read this information from a variety of planning systems, saving 30 minutes to 3 hours compared to manual entry, depending on the number of orders to be managed.

For example, ESAB's Columbus III CAD/CAM programming and nesting software enables parts to be imported from an existing assembly without the need for customized import filters. This provides more efficient data exchange from the software to the ERP system, eliminating the need for a costly, cus-tomized integration process.

CAD/CAM programming and nesting software automatically creates efficient part nests, such as this one, from plates.

In addition, the software tracks orders for cutting jobs. Information on multiple customers can be entered and all parts, orders and assemblies can be organized by customer for better workflow and more systematic data handling. Users can enter orders into the database to allow tracking of part status and material usage by customer, part and assembly. The sys-tem enhances plate management and lets users track orders throughout the system, so they know when orders are completed and jobs can be closed.

The automated nesting procedure is one of the most critical aspects of pro-gramming software for CNC shape-cutting machines. A variety of different machine technologies and cutting tools must be considered by the nesting algo-rithm, which must be capable of multi-tool nesting and using technologies like "n:m marking," which automatically cuts and marks with various cutting and marking tools. Imagine cutting with four oxy-fuel torches and then marking the parts with two arc markers or one inkjet printer. If these tasks are accomplished at the touch of a button, productivity can be increased by as much as 50 percent compared to manual processes.

Automated nesting assists in applying the appropriate machine and cutting tool technology to every part or even to every toolpath. As a result, productivity can be maximized even with automated multi-pass bevel programming for plasma Y, X and K bevels, which reference the shape of weld preparations on plate edges. Au-tomatically applying a sequence of pro-cess commands that have been proven in the field without the need for any pre-production testing eliminates hours of preparation work.

MBecause automated nesting works across several different machines, a cen-tral planning system can make a shop as efficient as possible. When end users have access to the complete order plan-ning information for all work and plate inventory, they can plan and nest more efficiently.

Though a complete nesting system of-fers much functionality, users of a CAM system must be properly trained to max-imize the benefits. Having a thorough knowledge of the workflow and ma-chine technology, as well as the train-ing levels of CAM system users, boosts productivity.

An automated nesting system can also measure the planned and real productivity of machines by calculating and monitor-ing production data automatically deliv-ered by the machines. Remember, if you can measure it, you can manage it. CTE