Courtesy of GF AgieCharmilles

In the world of sinker EDMing, less is definitely more. Smaller-footprint machines that run cooler and new technology that reduces electrode wear have made sinker EDMing more efficient. Also, better flushing and “just-in-time” electrode production is allowing some EDMing operations to expand lights-out machining, making the technology more competitive with hard milling.

Hot House

Replacing bulky, hot-running power supplies with cooler, smaller and higher efficiency ones is a big step forward in sinker EDMing, according to Steve Bond, EDM products national sales manager for Methods Machine Tools Inc., Sudbury, Mass. He explained how sinker customers are demanding smaller machine footprints and better performance at a lower cost, demands that are being met by machine builders like Exeron GmbH, Oberndorf, Germany. Methods is the distributor of Exeron sinker EDMs in North America.

“Power supplies on die sinkers have traditionally been bulky,” Bond said. “They’ve had large footprints and developed a great deal of heat within the power supply cabinet during the eroding process. Over time, this heat weakens the board components and reduces the efficiency of the power supply. As most EDM operators know, any change in the power supply can result in slower burning and reduced finishes. Consistency in power output is critical to the erosion process.”

Rather than continue to use fans and heat exchangers to cool the power supply, both of which allow air and therefore contaminants to enter the electronics cabinet, Exeron developed its liquid-cooled exopuls+ power supply. The compact power unit is about the size of a laptop computer, but capable of generating the same amperage as older, larger power generation boards.

A small pump in the machine’s dielectric system continually circulates filtered dielectric oil directly from the chiller to the power supply and back to the machine reservoir. This cooling process enables stable machining, while allowing the machine cabinet that houses the power supply to be completely sealed from outside contaminants, according to the builder.

Bond said the new system is more cost-effective and also provides extended service life and faster, more accurate burns than previous power supplies. Using exopuls+, graphite electrode wear during roughing and finishing is reduced by about 35 percent, while machining efficiency increases. In some cases, such as when applying electrodes with fine details, burn times are reduced by as much as 18 percent.

Smarter Sparks

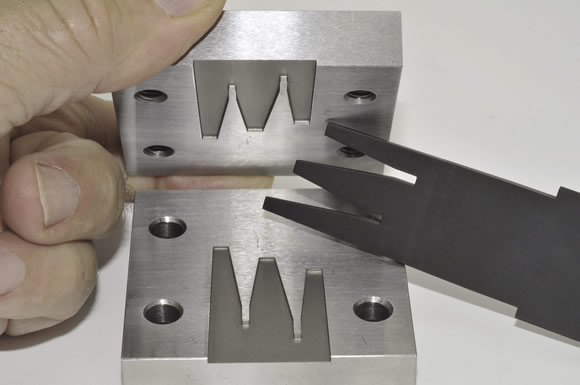

GF AgieCharmilles LLC, Lincolnshire, Ill., is another EDM builder touting new technology. Its IQ generator promises faster production, improved electrode life and finer finishes, in some cases dramatically. For example, a test case suggests upwards of 90 percent reduction in electrode wear is possible.

“This technology is really working. Shops are saving a small fortune by using fewer electrodes and less machine time overall,” said Ken Baeszler, product and aerospace market segment manager for GF AgieCharmilles.

Baeszler acknowledged that GF AgieCharmilles is not the only builder offering this.

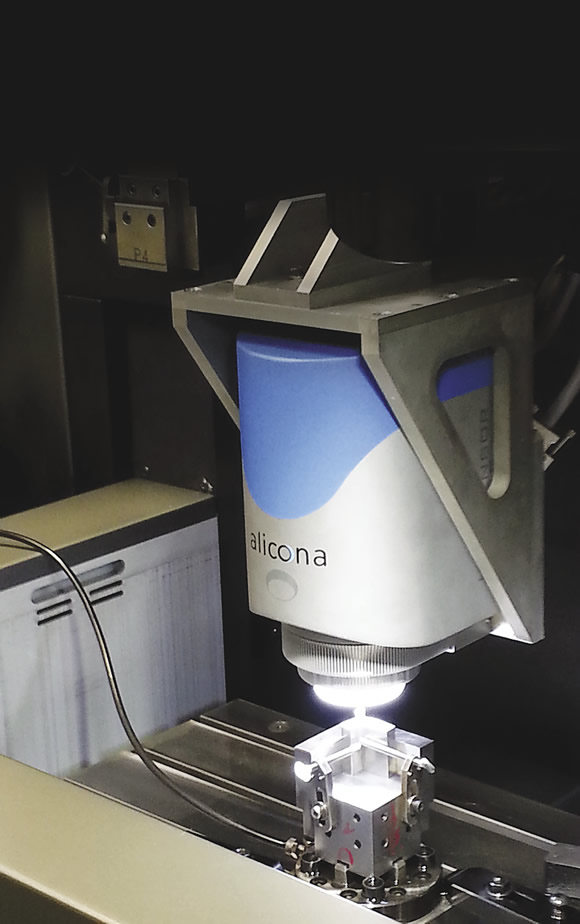

Courtesy of EDM Department

EDM Department performs in-process measurement on a Makino EDAF 2 sinker EDM using an Alicona white light measurement system.

Much of this reduced electrode wear comes from better spark control. “Micrographs of the burn area on older machines show kind of a random, splashy-looking spark discharge,” Baeszler said. “This led to inefficient stock removal and high wear rates. But if you look at an actual spark discharge on a new AgieCharmilles, you’ll see a perfectly smooth puddle of molten material. This is a result of our digital manipulation of the spark discharge, assuring a much more efficient spark, with less thermal damage to the workpiece and far less electrode wear.”

Electrodes aren’t the only thing GF AgieCharmilles is saving. Smaller electronics and design improvements mean today’s machines, such as AgieCharmilles’ Form 20, are roughly half the size of those built even 10 years ago, with no loss of travel or workpiece capacity. Baeszler said machine size is increasingly important. “We’re trying to put a lot of machine capability in a very small footprint.”

Pole Position

Deep burning is the focus of the new SuperSpark IV graphite technology from Makino Inc., Mason, Ohio. “One of the most prevalent processes we see in sinker EDMing nowadays is rib machining for plastic injection-mold features,” said Brian Pfluger, EDM product line manager. “This typically requires a very narrow, blade-type electrode, maybe 0.040 " wide at the tip with a 1° draft angle, to burn slots from 2 " to 4 " deep.”

In this scenario, wear is especially critical when in the roughing mode, which uses negative polarity. Therefore, 30 to 50 percent of the electrode might be gone before the electrode goes 1 " deep. “Negative polarity burns produce very aggressive metal-removal rates, but to the detriment of electrode life,” Pfluger explained.

Switching to positive polarity, typically for finishing, is a good news/bad news situation. “Due to positive polarity’s conservative cutting action, you could get by with one electrode but won’t deliver parts until Christmas,” he said.

According to Pfluger, SuperSpark increases production rates by automatically alternating polarity during the burn. This provides speeds equivalent to that of negative-polarity burning but with the electrode wear seen in positive-polarity conditions.

“SuperSpark gives you reasonable speed, but with total wear levels as low as 1 percent,” he said. This means a shop can use the same electrode for the entire burn and still achieve a uniform 40µin. Ra surface finish or finer in most materials. For most work, no further processing or hand polishing is required, according to Pfluger.

If electrode wear is less of a concern, why not just pour on the coals and get the part done faster? Pfluger said that’s certainly a possibility. “The operator has a choice. He can either use a traditional two- or three-electrode process for this rib detail to provide optimal throughput on the machine, or, if the shop is very sensitive to their electrode manufacturing costs, they can use this low-wear technology without sacrificing speed.”

Do the Hop

EDM builders are offering more than new smart circuitry. Moldmakers quip that successful EDMing requires three things: flushing, flushing and flushing. Anyone who’s operated a sinker EDM has watched the Z-axis pogo stick into and out of the workpiece as it clears debris from the burn area. Machine builders have minimized this lost time by using faster servomotors, but cleaning jumps are a time-consuming but necessary evil.

Courtesy of GF AgieCharmilles

Test burning a trident shape with IQ technology from GF AgieCharmilles.

Courtesy of GF AgieCharmilles

Fine details and deep ribs are sinker EDMed in a mold cavity using a graphite electrode.

“The faster you can jump in and out and reengage into the burn, the more efficient your processes will be,” Pfluger said. To accomplish this, Makino uses a series of “bunny hops” between large cleaning jumps. “Physically, you can only flush so much. After that, you have to get creative with your adaptive power control and machine jump settings,” he said. “We found that by programming a constant pulsing motion, it minimizes the need to pull the electrode all the way out to clear the cavity. It lets us stay engaged for a greater period of time.”

Another area where Makino has improved its technology is in titanium machining, a difficult material to EDM because of its thermal characteristics. “Basically, titanium likes to absorb heat, so it’s very hard to get an aggressive burn setting,” Pfluger said. By increasing the power supply to 120 amps and developing specialized burn conditions, Makino’s Titanium Booster boasts three times the productivity of previous machines. “Some of our customers will go in with a graphite electrode with a very simple shape and use it to hog out a titanium workpiece overnight,” Pfluger said. “It’s not as fast as conventional milling, but when you consider cutter life, the cost of endmills, and the fact that you don’t have to babysit the EDM as you would a machining center, your costs come out much lower by using the sinker.”

Windows of Opportunity

EDMs have been used for lights-out machining since the introduction of the toolchanger, which allows shops to load the machine with electrodes and go home. But, as Pfluger pointed out, many shops are less than excited about machining more electrodes than is absolutely necessary, automation or no. “We have certainly seen an increase in customers wanting to automate their manufacturing processes. On a sinker, this typically means integration of a graphite mill through the use of robotics.”

With the ability to machine electrodes on the fly, there’s no longer a need to premachine all the electrodes you think you might need. Shops can simply start burning and see how things go. Add the ability to measure the electrode and the workpiece with inline gaging and the door to unattended machining opens even wider.

Courtesy of Makino

Comparison of the electrode (middle) to the workpiece on the deep burn (see caption above, right) shows little wear.

Courtesy of Makino

Close-up of the sidewall on this deep burn performed on a Makino sinker EDM shows consistent surface quality throughout.

Someone who can speak to this point is Mark Raleigh, CEO at EDM Department Inc., a machine shop based in Bartlett, Ill. “With our closed-loop method, we don’t have to make a series of electrodes up-front,” he said. “We start with the initial electrode and evaluate the results after the first article. Since we have introduced sensing capability into the machine, we can measure wear, surface finish and form all in one system, while the process is running. Now, based on this capability, we can be proactive instead of reactive.”

That sensing capability is the R25, a high-resolution, 3-D scanning system from Alicona Corp., also based in Bartlett. As Raleigh explained, integrated measuring capability is critical to success with today’s short lead times and small lot sizes.

Raleigh said: “Manufacturing is dynamic in nature. You can plan all you want, but oftentimes you end up executing far differently because the information has evolved. The ability to dynamically measure wear and overburn and then feed this information to a cell controller means you can be more flexible, more efficient and, therefore, more profitable.”

Courtesy of Makino

EDM Department performs its own machine integration. Raleigh described a typical cell containing a graphite mill and sinker machine married to an articulated-arm robot, together with inline gaging to keep an eye on things. “We have 49 active jobs right now in the facility. Some have lead times as short as 36 hours, while others may run up to 8 weeks. Many of those jobs require customer approval of the first article, so there’s a delay of a few days to a week before we can go into production.”

Other jobs have to be expedited based on changing demand. The robot allows work to be shuttled in and out of the cell as necessary. And, if a job comes up short on electrodes, the robot can set that job aside and start on the next one in the queue while the mill gets to work making new electrodes.

No Stinkers

Flexibility like this allows EDM Department to be more responsive to customers. Raleigh summed it up like this: “About 40 percent of last year’s profits came from [jobs that involved] expedited delivery, so some customers are willing to pay more to have parts faster. The cellular concept allows us to manage our work more efficiently and take advantage of little windows of production opportunity. Sometimes, we can knock some time off the job by burning more aggressively and then maybe squeeze in a new job. If we have to make more electrodes, it’s no big deal. It’s a dynamic process.”

The rise of high-speed machining and hard milling in the die/mold industry might lead some to think that sinker EDMing is going the way of HSS cutting tools. But with faster burning capability, better electrode life and greater opportunities for automation, the machines some refer to as “stinkers” appear to be holding their own. Very deep part features, mirror finishes and materials harder than 65 HRC remain firmly in sinker EDM territory, and machine builders will continue to meet this need with ever more powerful advances in EDM technology. CTE

A new kid on the block

The newest sinker EDM technology can cut PCD and CBN, according to Dennis Powderly, national sinker and EDM drill product manager for MC Machinery Systems Inc., the U.S. distributor of Mitsubishi machine tools. Unfortunately, you’ll have to go to the company’s Wood Dale, Ill., office to see this latest and greatest offering: there’s only one machine in the U.S. with the new V series generator. “It’s so new I can’t even give you a spec sheet,” he said. “What I can tell you is that we tested it in Japan around 9 months ago and it worked great.”

CBN and PCD workpieces have traditionally been limited to wire machines when EDMing. As Powderly explained, this is because of wire EDM’s higher voltage, which can generate much shorter pulses than the circuitry used in sinker machines. No more.

Powderly said: “PCD and CBN are very brittle, but with our new V series generators we’re able to sinker EDM those polycrystalline materials without fracturing them. This isn’t so much about power. We’ve developed special circuitry that provides an extra boost, coupled with a very short pulse. The results have been quite promising.”

—K. Hanson

Contributors

EDM Department Inc.

(630) 736-0531

www.edmdept.com

GF AgieCharmilles LLC

(847) 913-5300

www.gfac.com/us

Makino Inc.

(800) 552-3288

www.makino.com

MC Machinery Systems Inc.

(630) 860-4210

www.mitsubishi-world.com

Methods Machine Tools Inc.

(877) MMT-4CNC

www.methodsmachine.com

Related Glossary Terms

- 3-D

3-D

Way of displaying real-world objects in a natural way by showing depth, height and width. This system uses the X, Y and Z axes.

- burning

burning

Rotary tool that removes hard or soft materials similar to a rotary file. A bur’s teeth, or flutes, have a negative rake.

- conventional milling ( up milling)

conventional milling ( up milling)

Cutter rotation is opposite that of the feed at the point of contact. Chips are cut at minimal thickness at the initial engagement of the cutter’s teeth with the workpiece and increase to a maximum thickness at the end of engagement. See climb milling.

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- polishing

polishing

Abrasive process that improves surface finish and blends contours. Abrasive particles attached to a flexible backing abrade the workpiece.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.

ARTICLES

ARTICLES