Magnetic workholders reduce setup, changeover times

Magnetic workholders reduce setup, changeover times

Electro-permanent magnetic workholders offer multiple advantages — even for nonmagnetic parts.

One goal all machine shops have is to improve overall shop efficiencies. Multiple paths are available to achieve that objective, including electro-permanent magnetic chucks when workholding is targeted. This type of magnetic workholding helps end users move more parts out the door, according to Mike Eneix, vice president of sales for Techniks Inc., Indianapolis. "It's all about optimizing setup time and part changeover time, and that's where a lot of productivity gains are occurring these days."

Two other types of magnetic workholders are available: electromagnets and permanent with rare earth magnets. However, unlike an electromagnet, an electro-permanent magnet requires only a short blast of electricity to activate or deactivate a chuck and continues to provide the same holding force even if disconnected from the power supply, Eneix explained. "You don't have constant electricity going to the magnet, generating heat and creating distortion or warping of the workpiece you are holding."

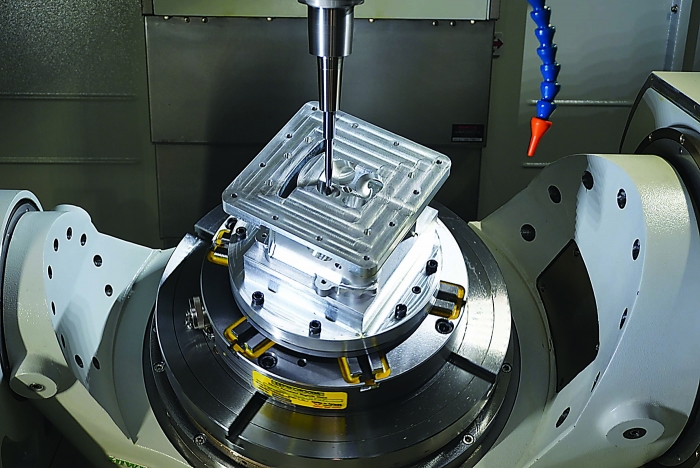

Magnetic workholders are suitable for holding workpieces for five-axis milling. Image courtesy of Techniks

From a safety standpoint, an electro-permanent magnetic workholder will not release a part if a facility loses power while the part is being machined, added Mitch Springer, president of Statesville, North Carolina-based Alpha Workholding Solutions LLC, which also specializes in electro-permanent magnetic workholding.

The company's magnetic workholders incorporate round pole technology instead of square or straight magnetic poles, Springer noted, adding that the technology provides an even balance between the north and south poles to more uniformly clamp a part. In addition, the technology minimizes stray flux, so chips don't adhere to the workpiece.

Permanent magnets using rare earth magnets are cost-effective for small workholding applications, Springer noted, but they must be activated manually, which requires internal mechanical parts that tend to eventually wear. Additionally, coolant can infiltrate a unit and deteriorate the internal components over time.

"On the electro-perm like ours, they are completely sealed," he said. "We have chucks out there that are over 15 years old and still going right along with no problems."

According to Michael Harris, national sales manager for the East Coast/Canada at Techniks, permanent with rare earth magnets are most commonly used for lifting magnets that don't require electricity. That type is also suitable for holding large parts more economically than an electro-permanent magnetic chuck. "You just need to position magnets every so often," he said. "You don't need the entire part covered with magnets."

Electromagnets are frequently found on grinding machines, Springer added. "There are still applications across the board for every type."

John Powell, president of Raleigh, North Carolina-based Wen Technology Inc., which focuses on the electro-permanent design, concurred. "When you have powerful requirements, then those revert back to electromagnets. When you have a small, detailed requirement, they revert back to permanent magnets. But for the general application, electro-permanent seems to be good for holding."

Hold Tight

Powell said a magnetic workholder can effectively grip almost any cast-iron or steel workpiece with the exception of some stainless grades, such as 300 series ones. In the case of tool steels, high hardness and high alloy content will reduce the holding power somewhat and their tendency to retain magnetism can make them difficult to remove from the magnetic workholder. Nonetheless, the possibility of machining five sides in one setup results in moldmaking being a major application for magnetic workholders. Also, magnetic workholders are available that effectively demagnetize a workpiece, and a major application for those is hard turning bearing rings.

When an end user isn't certain whether a workpiece material is suitable for a magnetic workholder, Springer said Alpha can make a recommendation based on the company's experience or conduct tests at its facility to determine if magnets are even feasible. An example is when the workpiece is an exotic metal or otherwise out of the ordinary. "We do a lot of testing for customers before they even go down the path of investing money."

Another workpiece material that many people think would be ideal for magnetic workholding is armor plate, but it isn't, Eneix said. He added that some stainless steel alloys seem to be magnetic but don't have enough carbon.

However, magnetic workholding can be employed even when machining aluminum and other nonferrous materials. The most common way is to build a steel fixture plate that mounts to the magnets while holding the nonmagnetic workpieces, Harris said. "That would shorten the setup time."

A-Pods hold a workpiece and are mounted on a tombstone for a pallet changer. Image courtesy of Alpha Workholding Solutions

Most conventional workholding is made of steel, Springer said. "It is usually mild steel. Mild steels are the absolute best to use with any kind of magnetic workholding simply because they magnetize really well and then they let go of the magnetism as well. You don't have residual magnetism."

Springer added that some people use Alpha's A-Pod magnetic modular system when switching between magnetic and nonmagnetic workpieces. Each module measures less than 101.6 mm (4") in diameter and 76.2 mm (3") in height, provides 635 kg (1,400 lbs.) of clamping force and can be placed and moved as needed.

"They set up the A-Pods where they need to go and do their magnetic parts," he said. "Then when they have to switch over to nonmagnetic parts, the A-Pods just clamp their magnetic fixtures that hold their nonmagnetic workpieces."

Enhancements, Developments

Magnetic workholders have a fairly long history, with electro-permanent magnetic workholding introduced in the U.S. in the mid-1990s, according to Powell, but they nonetheless continue to evolve. For example, he said Wen Technology offers intelligent controls that are fail-safe and enable problems to be easily diagnosed.

When a customer calls with a control problem, a blinking light sequence provides a code to indicate what is wrong, Powell said. "In a matter of minutes, you can get the situation sorted out. You can also prevent the electricity from flowing uncontrolled and damaging the chuck itself."

Using both the control and a specific wiring configuration for the magnets, Wen Technology is able to "fire" them sequentially, he said. This capability is shown in the photo below where a welded steel rectangular tube is held magnetically for machining. In this case, ensuring that the tube was straight was critical, so a magnetic side rail was integrated into the fixture. First, the side rail is magnetized to positively pull the tube straight in the y-axis against the rail, and then the base magnet is magnetized to pull the tube down in the z-axis and held straight automatically.

"You need to break the magnet up into separate firing zones and then sequence the part," Powell said.

Eneix said Techniks develops custom controller solutions for multiple magnetic chuck installations, which are common. If there are 10 chucks, for instance, the customer can control them individually, as groups or by part name.

"If you have a specific part that is always the same length and width, you may only need to magnetize chucks one through five," he said. "You could name it as such, and it will magnetize chucks one through five."

In addition, the control for Techniks' magnetic workholders enables the magnetic flux to be adjusted using eight flux height settings and prevent the flux line from coming through a part to avoid any chip buildup, Harris said.

Springer explained that the magnetic field protrudes from the top of Alpha's workholders about 10.2 mm (0.4"), so any part that thick or thicker will be fully clamped without any magnetism bleed. Conversely, the clamping will be reduced for parts thinner than 10.2 mm because some magnetism bleeds through.

"That's why we use that design, so you don't have flux seeping out everywhere," he said. "It's all contained. The side of the chuck is not magnetized. You are not going to have anything coming out there or the bottom. It only exits the top."

Using a magnetic side rail integrated into the fixture, a magnetic workholder secures a welded steel rectangular tube. Once gripped, the workpiece is both the y- and z-axes. Image courtesy of Wen Technology

To more effectively hold thin workpieces, which tend to bow, Eneix said Techniks offers 35 mm (1.38") pole magnets. The company also offers 50 mm (1.97"), 70 mm (2.76") and 90 mm (3.54") sizes for thicker workpieces.

"Once we came up with the technology for doing it in a 35 mm pole," he said, "that keeps the flex line a lot closer to the base of the magnet and allows us to hold on to exceptionally thin parts."

Techniks also offers spring poles that can be placed on the face of a magnet to compensate for any warped stock and eliminate shimming when holding parts, such as large plates. "The huge advantage in a shop is gaining productivity so you don't need to shim parts, so they will keep flatness before you machine them," Eneix said.

New to the Old

Even though the technology is well established, magnetic workholding is far from being universally understood and accepted when the application is appropriate.

"Every single week, it never fails that we talk to somebody who has never used magnets and doesn't know how they are going to work," Springer said. "Most of the market is just not that familiar with it yet or hasn't really decided to break free from what they are used to doing and trying something new, which isn't that new, but it just seems that way."

The benefits, however, can be eye-opening when someone is exposed to the technology.

"People who have never used a magnet for milling are typically shocked that the part is dead quiet," Powell said. "With any clamp-type system, you basically have point contacts, and the part is free to vibrate in between."

With magnetic workholding, on the other hand, a magnet has a much lower holding force per unit area of contact compared with a steel clamp, he added, but that lower force is over the entire surface. Therefore, the entire surface is clamped, and the part cannot vibrate. There is no screeching or squealing — just silence, a fine surface finish and long tool life.

In addition to significantly reducing setup and changeover times by eliminating the need to tighten and then undo a series of clamps or vises, magnetic workholding can help generate business.

"One job shop used to decline a specific job, and then they found (out) about magnets and incorporated magnets and all of the sudden went after that work," Eneix said. "They got the work and made great margins on that work as well."

For more information about magnetic workholders from Alpha Workholding Solutions, view a video presentation at www.ctemag.com by clicking here: cteplus.delivr.com/2c33a