Maxing out multitasking

Maxing out multitasking

Get the most from combination turn/mill machines.

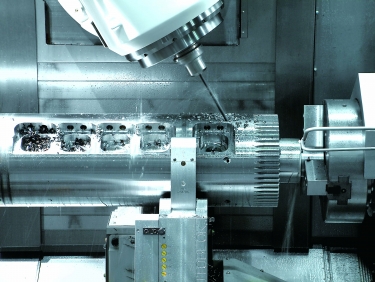

If you turn and mill workpieces, it's time to take a hard look at so-called multitasking machines. Capable of both turning and milling, these machines eliminate the need to move workpieces that require both operations from one machine to another, as well as any error that results from the transfer. In addition, multitasking machines reduce setup time and positioning fixtures.

"You're not making any money when you're moving parts from one machine to the other," said Joe Wilker, advanced multitasking manager at Florence, Kentucky-based Mazak Corp. "The only time you're making money is when the material is in the machine and you're making chips. So what we say is, pick up the raw material one time, put it in a machine, machine it complete, put it in a box, and ship it. That's the concept of multitasking: a single platform for all your machining needs."

Machining firms that employ multitasking have a variety of choices to make involving both the equipment they use and their approach to this machining strategy. Making the right decisions can help them go beyond the inherent advantages of combining turning and milling in a single platform and truly excel at multitasking.

Not Right for All

Before making these choices, however, potential customers must determine whether multitask machining is correct for their situations. For one thing, multitasking might not fit into the budget of every company that wants to utilize it. A multitask machine is more expensive than a turning center and a basic vertical toolchanger. See toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: automatic toolchanger">automatic toolchanger." title="CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger." aria-label="Glossary: machining center">machining center combined, and the cost is on par with some 5-axis VMCs, said David Fischer, lathe product specialist at Charlotte, North Carolina-based Okuma America Corp.

Doosan's DVF 5000 multitask machine (left and above) enables simultaneous 5-axis machining. Image courtesy of Doosan Machine Tools America

Another consideration is the kind of parts a manufacturer makes.

"We have heavier-duty multitasking machines, but for the most part they're made for a lot of finesse and creating complex geometries," said Robert Appleton, deputy general manager of application engineering at Doosan Machine Tools America Corp., Pine Brook, New Jersey.

So a multitasker might not be the better choice for machining simple parts or extremely heavy parts that require more rigid turning and not much milling.

"If you're making something like a tube for an oil well, you're probably better off with a larger single-purpose machine than you are with a multitasking machine," Appleton said.

Additionally, multitasking is generally better for small and medium lot sizes because multiple stand-alone machines can apply more spindles to the task.

"If you're going to do 150 to 200 parts, multitasking is a no-brainer," Wilker said. "But if you want to do 1,500 in a week's time, it may make sense to use stand-alone machines. Our Integrex machine might only have a milling spindle and a lower turret, which means it has only two tools in the cut at any given time. But if you use (several) stand-alone machines, you could have three or four spindles going at the same time doing different features."

A Changed Landscape

If part manufacturers move ahead with multitasking, they will discover that the landscape has changed dramatically in two decades.

"In the early days, a lot of sacrifices were made in order to do both turning and milling on a single machine," Fischer said. "But across the industry, the technology has progressed and machine designs have changed radically over the last 20 years, so users are making much fewer trade-offs."

Consider, for example, a basic Okuma turret lathe with milling capability that was on the market 20 years ago.

Okuma's Multus U4000 multitask machine (below) has a 240° B-axis range. Image courtesy of Okuma America

"These types of machines did minimal milling work and 85% turning," Fischer said. "But over the years, the systems have improved so that now they can do significant milling."

For one, he said, the horsepower and torque of milling machines have increased, allowing heavier cuts. Other significant upgrades include improved software and servo systems, which have boosted accuracy for machining intricate parts. In addition, controls have become easier to use, making complex multitasking machines more accessible to operators.

With Okuma's Multus multitask machines, "there are virtually no trade-offs at all," Fischer said. "The turning capabilities are as good as any lathe of comparable size, and the milling capabilities are as good as any mill of comparable size."

Impact on Tools

The Multus features a turret that rotates around a B-axis so tools can be used in multiple orientations, allowing the creation of side holes, for example. The machine holds up to 180 tools, Fischer said. Even if users can't put all the tools for their jobs in the machine at the same time, the control can monitor up to 999 tools.

"So if you have to switch out some tools between jobs, the control is managing that to significantly reduce setup time," he said.

No matter which multitask machine you choose, buy the biggest magazine you can afford, Wilker

said. This capability allows users to have more jobs queued up and ready to go.

Additionally, Fischer said a large automatic toolchanger holds more backup tools. This is particularly helpful when machining abrasive materials, which quickly wear out tools. When this happens, having backup tools in the magazine allows the machine to continue running.

Appleton said Doosan equips most of its large multitaskers with Coromant Capto C6, a modular quick-change tooling system. Doosan is "very happy" with this system's accuracy and repeatability between tool changes, he said.

All Doosan multitasking machines can accommodate FANUC Focas and MTConnect. Focas is a set of library files that can access almost all the information inside a FANUC CNC. MTConnect is a technical standard for retrieving process information from shop floor equipment. The combination allows manufacturers to monitor processes and make necessary adjustments, Appleton said.

Although multitask machines are mainly for small and medium lot sizes, some users may wish to boost the volume from medium to the medium-to-high range. Wilker said one option for doing so is simultaneous machining performed by an upper milling spindle and a lower turret for turning. While the lower turret machines one side of a part, the upper spindle can machine another side.

Users of multitask machines may also want to check parts for accuracy with a touch probe before removing them from the machine. By measuring parts in line, the probe can spot those that are out of tolerance more quickly than an offline measurement system, thereby preventing more bad parts from being made.

Mazak's Integrex e-H multitask machine features a B-axis milling spindle with Y-axis capability. Image courtesy of Mazak

However, measuring parts during the machining process increases cycle time—a sacrifice that some users would rather not make.

These users "want their machine to make parts and chips, so they'll take a part out of the machine and measure it while the machine is making another part," Wilker said.

Conventional or Conversational

As for programming, Mazak's Integrex multitask machines offer two options: conventional EIA/ISO programming done using a CAD/CAM system and so-called conversational programming done using a feature called Mazatrol. Mazatrol asks the operator questions about the raw material, cutting tools, feature dimensions and other elements the control needs to know to properly machine a part. When asked a question—for example, "What is the OD of the raw material?"—the operator simply enters the value using a touch screen. Personnel at small job shops can quickly complete this process at the control in much less time than it would take to write an EIA/ISO program to give the same information to a machine, Wilker said.

Mazatrol, which some shops use exclusively, is "definitely preferred from a user-friendliness standpoint," he said, but the situation is different for some of the bigger machining operations. "They may use Mazatrol when they're making a simple part, but (for the most part) they have a staff of CAD/CAM people programming their machines."

In some cases, this is necessary because Mazatrol can handle only up to 4-axis programming.

"When you get into 5-axis contouring-type programming, you need a CAD/CAM system to generate the toolpath," Wilker said.

Wherever conventional programming is done, to optimize multitasking, those doing the job should be knowledgeable about more than just a single machining operation.

"Programmers need to be a little more 'multitasking' in terms of what they do," said Jeffery Sturtevant, key aerospace accounts manager at Doosan. "You need people who know good milling practice, good turning practice and how to combine both of them."