Optimizing nesting software’s benefits

Optimizing nesting software’s benefits

This month's Get With The Program column in Cutting Tool Engineering looks at the benefits of nesting software for shops that make parts from flat raw materials.

Nesting software provides machine shops that manufacture parts from flat raw materials with an efficient and intuitive way to implement advanced cutting operations. Whether cutting with a laser, waterjet, plasma, oxyfuel or combination punch press machine, the right nesting software can help boost throughput, improve part quality and reduce costs through lower workpiece material consumption. It's not uncommon for manufacturers to discover their nesting software has more than paid for itself within just a week or two of use.

Look closely at the features included with the nesting software and ask the following questions:

- Does it have the needed geometry-creation tools, such as a standard shapes library and integrated CAD system?

- Does it import an array of 2-D and 3-D file formats along with bill of materials information?

- Beyond the traditional manual and automatic nesting features, does it automatically control part orientation relative to the material grain?

- Does it prevent a part from nesting within the interior profile of another part, if desired?

The automated application of advanced process data based on material type, thicknesses and grade is increasingly important. Be sure the software contains advanced and accurate machine-specific parameters and built-in cutting process expertise. This helps achieve optimal hole quality and fine feature detail and provides consistent and repeatable results for applications such as bevel cutting.

There are two more questions to ask: Is the software flexible enough to integrate into an existing operation, such as connecting to a material requirements planning/enterprise resource planning system to share work orders and inventory data? And, how much can job data be configured to meet specific business needs, such as custom report formats?

As important as it is to understand the standard features of the program, it is also critical for nesting software to be modular. A modular structure ensures the user isn't spending money on unwanted or unneeded tools, which can be added later when a new job justifies the purchase.

In addition, be certain the software is intuitive and easy to learn so new users don't spend days or weeks trying to familiarize themselves with the program. Some programs get users up and running in an hour or two. Plus, nesting software that is user-friendly and contains a high level of automation enables users to operate the program more efficiently and avoid costly errors that lead to scrap.

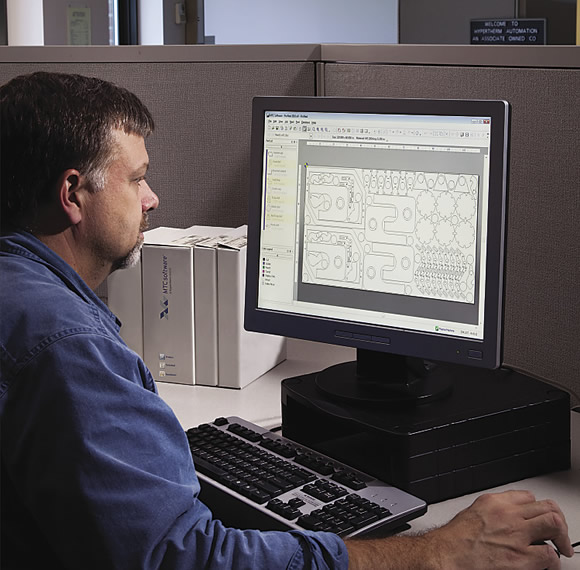

Courtesy of Hypertherm CAM Solutions

Nesting software that is user-friendly and contains a high level of automation enables users to operate the program more efficiently and avoid costly errors that lead to scrap.

And don't forget the quality of post-sales support, specifically technical support, from the nesting software developer. Specific questions to ask are:

- Is there a limit to how many times a customer can access support or is it unlimited?

- How experienced are the technical support specialists and do they understand the specific cutting applications?

- Does the manufacturer offer online training and other opportunities to expand proficiency with the software?

- Are software upgrades included with an annual subscription program?

Getting answers to these questions prior to purchasing will help a shop maximize uptime and optimize results from the nesting software it chooses. CTE

About the Author: Derek Weston is program manager for Hypertherm CAM Solutions, Hanover, N.H. For more information about the company's nesting software, including ProNest, TurboNest and NestMaster, call (800) 643-0030 or visit www.hyperthermcam.com.