Precision Key to Boring Bearing Pockets

Precision Key to Boring Bearing Pockets

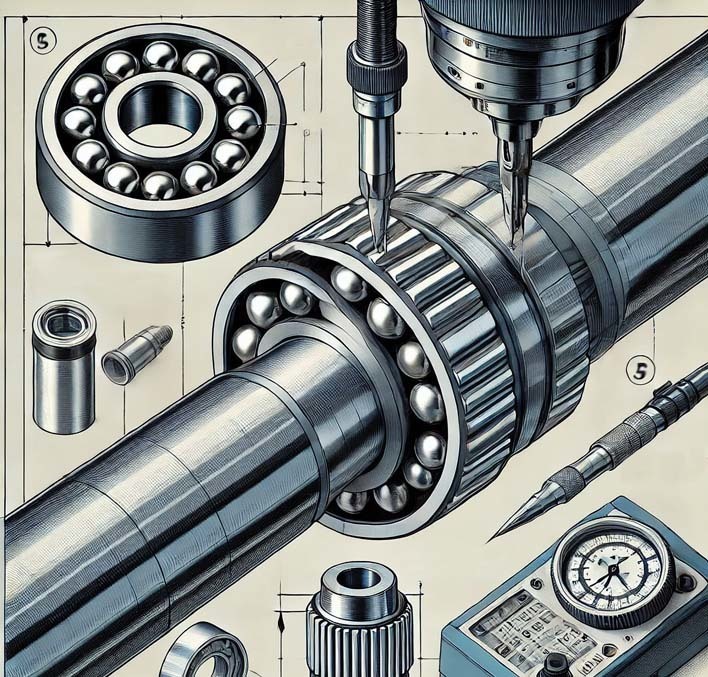

Bearing seats must be straight, round, sized correctly and have the proper surface finish. Without these characteristics, you risk premature failure.

Machining is the costliest method we have for creating part geometry. When possible, engineers will rely on casting, forging, welding and similar processes and avoid machining wherever they can. However, there are some geometric features that must be machined to ensure the integrity of the component and the final assembly.

Rotating components, like shafts, and the supporting features like bearing housings, are good examples of features that must be machined to ensure integrity of the product. Obviously, creating precise features on a shaft is critical to proper operation. Likewise, the features that support the shaft bearings are critical like those of the shaft.

Bearings are usually pressed into a "seat" creating an interference fit that holds the outer race of the bearing stationary. Bearing seats must be straight, round, sized correctly and have the proper surface finish. If these characteristics are not maintained to the design requirements, the assembly can suffer premature failure.

In most designs, bearings operate in pairs. Alignment of the bearings is a critical factor as misalignment can cause shaft wear, bearing failures, eccentric shaft motion and other problems. Obviously, bearing alignment is dependent on the accuracy and precision of the machined bearing seats.

Machining the seats without repositioning the part is the best solution. In many situations this is not a difficult task and can be accomplished with standard tools. When parts are very large or bearing bores have a large depth-to-diameter ratio things can be difficult.

When the boring tools get long, they can chatter and will droop under their own weight. Ultimately, they are unable to create the de sired geometry. One way to solve this issue is by installing guide bushings that support the cutting tool as it bores the seats. In high-volume settings the guide bushings are installed in the workholding and have little impact to the machining time.

In low-volume settings the cost of complex fixtures with guide bushings is prohibitive. Machinists and engineers must get creative sometimes. It is possible to bore one of the seats, install a guide bushing and use it as a support for the second bore.

Field machinists have a plethora of tools for "line boring," which is the term used for boring long, straight bores. These devices used in field machining can appear crude compared to a nice boring mill or vertical lathe, but they work well for creating straight, accurate bearing bores when the job can't be taken to the shop.

Having bearing seats that are well aligned is no good if the seat is the wrong size. Maintaining proper bore diameters ensures the bearing fits in the seat as designed. Using a good boring tool that is set correctly and paired with the proper cutting parameters is the first step to sizing a hole correctly. Find a good cutting tool manufacturer and let them guide you to the best tool for the job. Modern boring tools are phenomenal, and finding a tool for boring tight tolerances has never been easier (or more expensive).

In the modern machine shop, diameter issues are more often a metrology issue than a cutting tool issue. Air gauges are the most accurate way to check bore diameters. Air flows through a small orifice that creates back pressure when the flow is restricted. After being set with a master ring gauge, a low pressure reading indicates a hole that is larger than the master. Conversely, a high pressure reading indicates a diameter that is smaller. Air gauges are expensive and usually reserved for high production or extremely expensive parts.

A high-quality dial bore gauge is sufficient for measuring most bearing seats when the added cost doesn't justify an air gauge. Like the air gauge, it is always best to set the dial gauge with a gauge ring. More than once, I have seen parts rejected when someone used a micrometer to set a bore gauge. That's a common, but risky practice.

Sometimes there is a roundness requirement on the drawing that mandates a roundness check, and it is a good practice to check roundness even when there is not a tolerance. Both types of gauges are also good for checking roundness of the bore.

I witnessed a machining line in the automotive industry scrap a lot of parts that an air gauge indicated were good. The bearing seat was machined with a rough and finish-boring operation. The roughing tool was set wrong and did not leave enough stock for the finish tool to correct the clover leaf shape left by the roughing tool. After finishing, the hole was lobed where the finish tool cut in some places but not in others. Machinists could not see the problem because the diameter was about 10" deep in the part. If we had been checking roundness, the problem would have been detected sooner.

Surface finish of the machined seat is less critical to bearing and shaft life than the other elements. This does not mean it can be ignored. Surface finish can affect the fit of the bearing to the seat reducing the amount of interference between the two. If the surface finish is not specified, there are design specifications published by the bearing manufacturers that give recommended surface finishes for bearing seats.

Rotating components can be exposed to severe conditions like high loads and high rpm. While the type and quality of the bearing is the primary engineering consideration, the structures supporting the bearings influence the function and life of components in the system. Machining bearing seats is one of those operations that requires additional care and attention to ensure equipment works as designed.