Proper mist collection necessary for shop floor safety

Proper mist collection necessary for shop floor safety

The metalworking fluids commonly applied during machining processes generate airborne mists that must be carefully controlled.

The metalworking fluids (MWFs) commonly applied during machining processes generate airborne mists that must be carefully controlled. Otherwise, the mists pose a variety of health risks to workers and create a dirty and unsafe work environment. It is important to understand the hazards associated with oil mists, as well as exposure limits set by the Occupational Safety and Health Administration (OSHA) and other entities. This article will review these issues and describe the role of proper mist collection in keeping machine tools and the surrounding shop area clean.

Regulations and Guidelines

The emissions generated by machining processes are formed because of a combination of mechanical and thermal effects and fall into three general categories:

- Coolant-mist liquid aerosols, which are formed via condensation as a result of cooling or mechanical processes.

- Coolant vapors, i.e., gaseous-phase substances that result from heating liquid coolant.

- Coolant fumes, the finest solid particles in the air, which are generally formed during combustion processes.

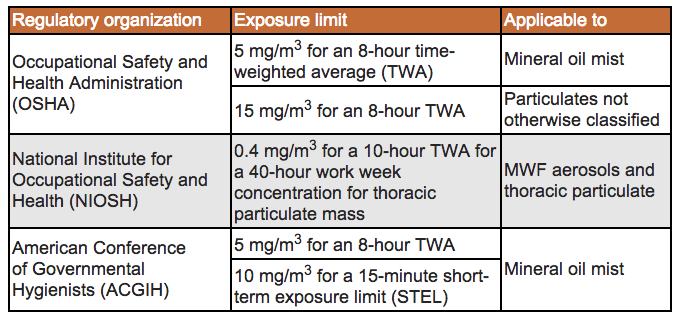

Three different entities have established and published exposure limits that apply to MWFs: OSHA, National Institute for Occupational Safety and Health, and American Conference of Governmental Hygienists (Table 1 below).

Table 1. Exposure Limits for Metalworking Fluids

OSHA also published the Metalworking Fluids: Safety and Health Best Practices Manual in 2001, which incorporates recommendations from multiple sources. It does not carry the force of law or regulation, but it is meant to be advisory and informational. Its goal is to help employers develop prevention programs that will create safer workplaces for employees exposed to MWFs.

The list of adverse health effects associated with MWFs is long. It includes respiratory ailments such as asthma, chronic bronchitis and hypersensitivity pneumonitis; pancreatic, colon, bladder and liver cancers and tumors of the brain and respiratory organs; contact dermatitis, eczema and other skin disorders; irritation to the respiratory tract and mucous membranes; and changes in organs, as well as potential nerve damage, damage to genetic material and immune

disorders.

The exposure limits defined in Table 1 have been developed to protect workers against many of these adverse health effects. If your facility is meeting OSHA requirements but workers are still experiencing symptoms, it may be necessary to set lower limits.

There are two general categories of MWFs used in machining processes:

- Emulsion coolants: Water-soluble and water-mixed coolants are cooling-lubricant concentrates that are diluted with water, to their usage concentration, prior to use. The oil or lubricant proportion is typically about 5 to 11 percent. They offer effective heat dissipation and are used primarily for cooling.

- Pure, or "straight oil," coolants: Non-water-soluble coolants are not mixed with water and are used according to the composition provided by the manufacturer. Straight oils are generally used for their excellent lubricating properties–unlike water-mixed emulsion compounds, which provide some lubrication but primarily cool.

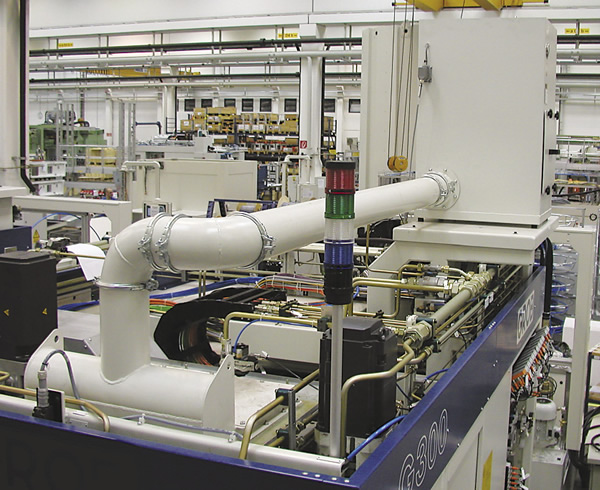

Figure 1. A fiberglass V-bag-style mist collector.

Mist Collectors

A variety of equipment captures mists generated when these coolants and lubricants are applied. Most commonly used are multiple-stage, fiberglass V-bag mist collectors (Figure 1). These units feature a first-stage Chevron metal filter, a second-stage aluminum mesh filter and a third-stage fiberglass V-bag with a 95 percent ASHRAE (formerly American Society of Heating, Refrigerating and Air-Conditioning Engineers) efficiency rating. The efficiency rating is a bit misleading in that it has nothing to do with oil removal. The ASHRAE rating system is used to measure efficiency in removing dry particulates. Most units also offer an optional fourth-stage HEPA final filter for added protection and cleanliness. A HEPA filter is usually designed to remove 99.97 percent of airborne particles measuring 0.3µm or greater in diameter.

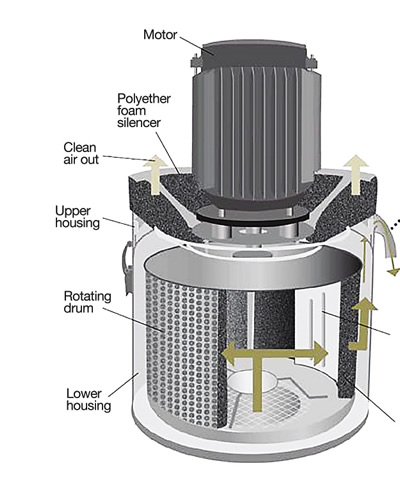

Also prevalent are centrifugal-type mist collectors that use a rotating drum to spin the oil (Figure 2). Typically, a pad inside the unit functions as a final filter, but most contaminants are removed by the rotating action of the drum. If chips collect in too high a volume, the unit can become unbalanced and malfunction, creating a health hazard and a maintenance headache.

Figure 2. A centrifugal-type mist collector.

Both styles of collectors are usually designed for double duty, meaning they are used on straight oil and emulsion coolants. As a rule of thumb, they work well in light-duty applications but are not as effective for heavy-duty use and long production runs. V-bag and centrifugal collectors have a relatively low initial cost but are limited in terms of run time, filter service life and filtration efficiencies.

Because of these limitations, many parts manufacturers recognize that one collector size and type does not fit all applications. Straight oils and emulsion coolants have different properties and characteristics. As a result, consider a

collection system that is specifically engineered for use with one type or the other.

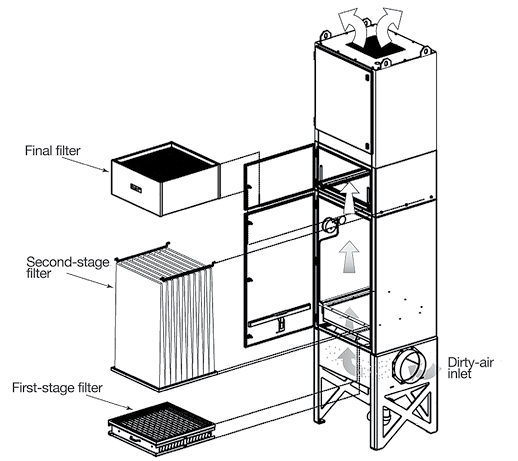

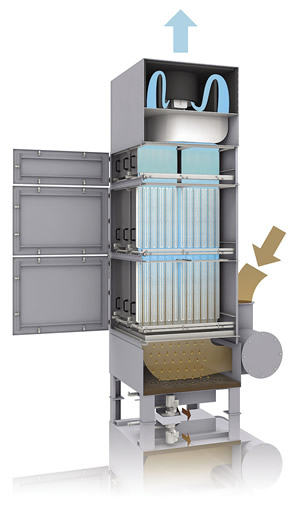

Figure 3. A high-efficiency mist collector for emulsions and coolant oils.

Figure 3 shows a high-efficiency mist collector for removing airborne contaminants emitted by water-based coolants and emulsions. It uses two stages of long-life coarse and fine-filter demisters and a final-stage HEPA filter; the high-efficiency mist collector offers a capture efficiency of 99.9 percent on particles 0.3µm and larger. This is much higher than the capture efficiencies achieved with fiberglass V-bag filters. The HEPA-filter stage is optional and is typically used for processes that generate smoke or very fine particulate.

This unit also has a patented integrated spraying system that performs two functions: It counteracts emulsion "clumping" in the system by maintaining the correct balance of water to oil, and it cleans the demister filters. This self-cleaning system reduces maintenance and extends filter life.

Figure 4 shows a mist collector designed for pure or straight lubricant oils. A first-stage coarse-mesh filter removes large particles and chips, followed by two stages of diffusion filters: a prefilter and fine filter. Media separators in the filter packs allow optimal airflow while providing maximum usable media area within a compact space.

This design combines high-efficiency separation performance and a self-cleaning capability via drainage of the separated cooling lubricant. Benefits include reduced energy consumption, extended filter life and enhanced protection of the optional HEPA final filter, which may be used for removal of ultrafine mists, clean-air recirculation or both.

Figure 4. A high-efficiency mist collector for straight oils.

Achieving separation efficiencies up to 99.97 percent on 0.3µm and larger particles, it can operate 24/7 and withstand the most challenging applications.

Design Considerations

When designing equipment for mist removal, the best solution is a source-capture collection system that will contain mist at the machine. Ceiling units that provide ambient ventilation are sometimes used. However, these will remove some of the mist but are not as effective as source-capture systems.

The design challenges are greater when retrofitting older machine tools with mist collectors. Machines built 20 or 25 years ago were often not designed for mist collection. Newer machines have better ductwork designs and provide better airflow patterns to pull air out of the machine at the recommended airflow (measured in cubic feet per minute).

Any time you can reduce the load on a collector, it's a good thing. Lots of metal chips can drastically shorten filter life. A general rule is to maintain a slight negative pressure when machining. This will augment the capturing of fine mist without pulling chips, emulsion or oil into the collector.

One recommended option is to equip the oil-mist or emulsion-coolant-mist collector with a variable-frequency drive. During machining, the VFD speed should be reduced to a level just adequate to contain the mist in the machine. In a newer machine that is fairly airtight, you may be able to ramp down to 25 percent of full airflow while the doors are shut. Maximum airflow when the doors are shut can pull mist and chips into the collector and plug filters.

When it comes time to change parts and the doors are open, the fan can be ramped up to full airflow. It is advisable to keep airflow at 50 to 75 feet per minute (15.24 to 22.86 meters per minute) through the door opening while changing parts to keep the mist inside the cabinet. The best-designed systems leave most of the oil and all of the chips in the machine.

Another strategy is to use a special chip gate to separate chips and preclean the oil. Basically, it acts like a horizontal cyclone designed for the airflow you need in the machining center. Chip gates can sometimes be retrofitted onto older equipment.

Equip ductwork with fittings and seals made specifically for oil. There is a misconception that mist collectors and ductwork always leak. That is not the case. If leakage occurs, the causes usually are unsuitable fittings and seals. Also, make sure the cabinet is leakproof and won't allow oil to seep out. Otherwise, employees will be at risk of slipping and falling on oily floors. Even small cracks allow oil to seep out.

General Work Practices

You can tell when you walk into a machine shop whether or not good work practices are being observed. When they are not, you can literally smell, feel and taste the oil in the air. There are many factors involved in keeping machine shops as safe and clean as possible:

- Always employ best-practice mist collection. As noted, it is often preferable to use a collector designed specifically for either oil-mist or emulsion-coolant-mist removal, as opposed to a "general-purpose" collector. This is particularly important for machines used for heavy-duty applications and long production runs.

- Require the supplier to provide a written guarantee on filter life and emissions performance. Also, look for equipment that has been dye-tested and certified as leakproof by the manufacturer.

- Inspect equipment regularly to make sure it's working as designed. Sometimes, emissions will be fine at startup, but that may change after the collector has been in operation for a significant amount of time.

- Frequently collect air samples to make sure you are well within the required personal exposure limits. Monitors that measure emissions and show milligrams per cubic meter being emitted are suitable for testing within the facility. If you suspect a problem or need independent verification of emission levels within the facility, it is best to hire a company that specializes in air-quality testing.

- If you see oil on the floor, be sure not only to clean it up but also to find the source and take corrective measures to stop further leakage.

- Monitor trends in the differential pressure across the filters and make sure pressure is within the manufacturer's recommended operating range. Pressure monitoring should be done daily. There are a number of monitoring devices available that will measure differential pressure, as well as other critical functions, and trigger alarms at designated set points.

- Train and educate employees on the health risks associated with overexposure, on good work practices and on the importance of good housekeeping.

- Require handwashing several times a day if workers do not wear gloves. Do not allow workers to wear fluid-soaked clothes.

- Prohibit food, beverages and any other personal items in any work area that may become contaminated.