Pulling through

Pulling through

A Chicago broaching shop remembers its past to invigorate its future.r

Operator Salvador Leanos at V W Broaching Service sets up a ball valve to broach an internal spline.

In many ways, one cannot think about the future of a broaching company like V W Broaching Service Inc. without thinking about its past. Broaches stored along a wall, hundreds of them, new and old, are visual reminders of countless jobs, of past challenges, of literally the blood, sweat and tears of a family, the Roschman family.

Patriarch George Roschman started V W Broaching nearly 60 years ago, and his family lineage can be seen today. His son Russell Roschman serves as president, and grandson Steve Hanna as vice president, with other family members working in the front office.

The business began in 1955 in a rented basement, and, by 1959, had moved into its current 54,000-sq.-ft. facility, located next to the elevated railway tracks that run along Chicago's Lake Street.

While much of the company has remained constant over the years—its location, leadership and many of its employees—that doesn't mean the company stands still. Acquisitions and investments in new technology have increased capacity and capabilities.

Over the years, the company has produced just about anything and everything, from farm equipment to medical device components, parts for rockets and knobs for consumer electronics. Diversification, Roschman said, is the key to the future, as it was to its past.

In the 1960s and 1970s, the company flew high on sales to the automotive industry, literally by keeping passengers from flying out of their seats. The company produced millions of seat belt components. Eventually, that business faded.

"I miss the old days of having jobs like broaching 11.5 million seat belt pins that held seat belts into a carriage," Roschman said. "Those were wonderful days, when the customer would literally back up the truck with broaching jobs for us."

Today, the company compensates for the loss of high-volume orders by serving a wider range of clients, with more than 2,000 active customers around the world, according to Roschman.

One of its biggest current projects harkens back to broaching's roots in rifle making. The company has a major contract to broach rifle stock and create the well that holds ammunition magazines on the AR-15 semiautomatic rifle. In the 1800s, job shops often broached, or rifled, weapons with broaching tools not too dissimilar to today's cutters.

Tooling ExperienceJust as in the 1800s, and in the 1950s when the business began, the quality of the cutting tool is the key to effective broaching. V W Broaching has an expert broach maker in Tooling Manager Brian Gillund, who brings more than 30 years of experience to the task. Preferring his practiced touch and simple grinders over automated methods to make and maintain the tools, Gillund can often be found hunched over a broach, measuring and fine-tuning tools.

Broaching, in the main, is not a difficult concept, but the devil is in the details, such as a finely honed edge and the pitch of a cutting tooth. A broach combines roughing and finishing in one operation, and often in one pass, where the broaching tool is pulled through the workpiece. The tool consists of a series of teeth, with each tooth removing a small amount of stock, and the teeth are gathered into three distinct cutting sections. The first set is the largest and does the rough cut, the second set semifinishes, and the last set, with the fewest teeth, imparts a fine finish.

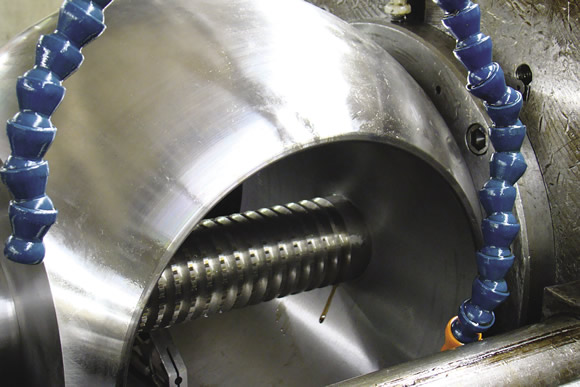

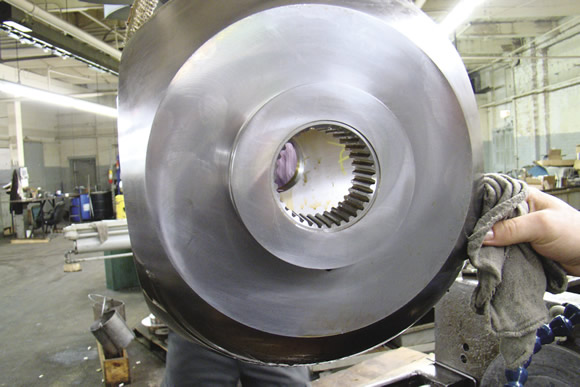

V W Broaching used a horizontal broaching machine (above) to cut an internal spline on this 24"-dia. ball valve. Below: In a few seconds, this spline was broached.

The secret to a fine finish, said Tim Espy, production manager, is in the gradual increase of tooth height over the length of the tool. This rise per tooth determines the amount of material removed and chip size. The rule of thumb for rise per tooth is 0.0025", he added, but varies according to finish requirements.

As opposed to yesteryear's relatively soft, ferrous tools, today's broaches are made from HSS, heat treated and coated to increase the tool's surface hardness, lubricity and wear resistance. The broaches are often made from PM-M4 HSS, hardened to 65 HRC.

In addition to the broaches it makes for the jobs it runs, V W Broaching also produces custom and stock broaches for customers who do their own broaching, and sharpens and reconditions the tools.

Broaches are designed with a proprietary CAD program or CAD files sent in by its customers. While most broaches start with a part drawing, V W can reverse engineer from an existing part.

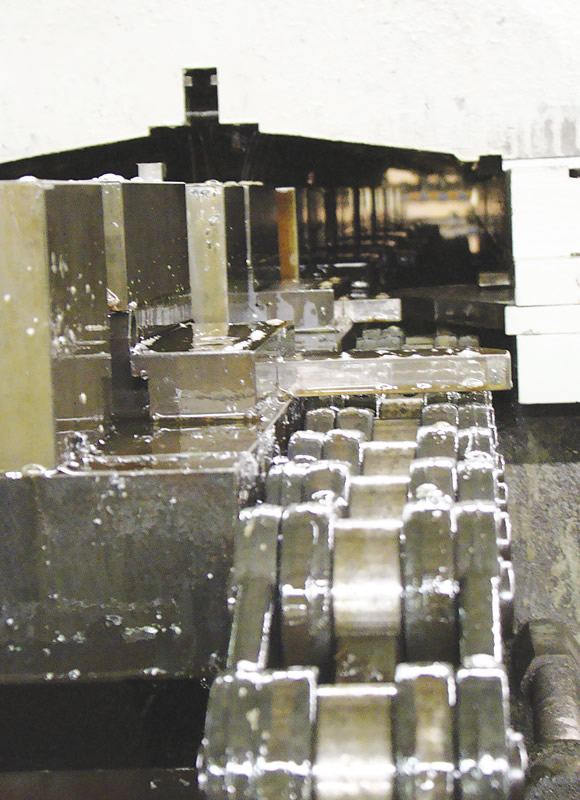

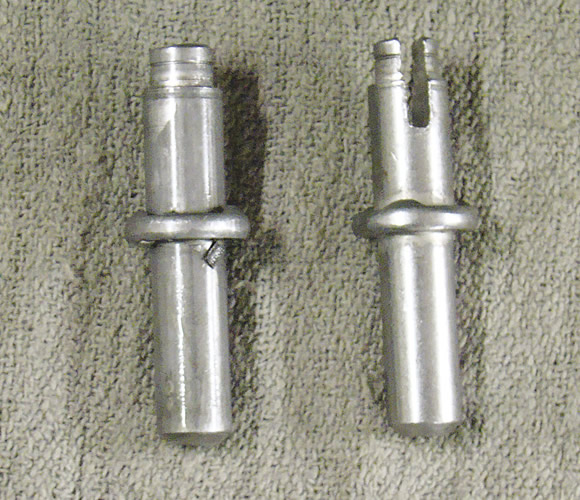

The chain on a continuous-chain broaching machine pulls parts through the work envelope (above), where multiple cutting tools remove stock. Below: A part before and after a slot is cut on the tip using a continuous-chain broaching machine.

"Typically, the part to be reverse engineered will be something like a splined hub that connects a wheel to a shaft, and the customer comes in with a shaft or a hub and wants the mate," Gillund said. "That's a challenge, because we have to design a tool to figure out what the spline specs are through careful, multiple measurements, then design a tool to make the spline cut."

Most broaches at V W Broaching are owned by customers, but left at V W's plant. Keeping the broaches maintained and ready for use is a key issue, in part, because of the long lead times for new broaches. A broach in the 6"- to 7"-dia. range could take 8 to 10 weeks to produce and cost up to $25,000, Hanna said. If properly maintained, however, the broaches can last for years and drive down the cost per part to pennies, he added.

The tradeoff of this high cutting tool cost is the high cutting speeds and short cycle times broaching can achieve. Broaching speeds vary from 20 to 120 sfm, and cycle times are typically from 5 to 30 seconds. For example, the cycle time to broach the AR-15 well is about 5 seconds.

More than MillingBroaching's lightning-fast speed has helped keep competing processes like CNC milling at bay. When broaching internal part features, for instance, "then it is no contest, broaching wins. It is simply too fast," Roschman said.

Also, if the internal feature has a square-sided shape, it typically cannot be done with a CNC mill because the cutter has to spin, and that usually eliminates any job with such a feature. "Jobs with square-sided internal or external shapes can really only be done by broaching, wire EDMing, laser cutting and waterjetting," Roschman said.

Operator Antoine Osby broaches a part.

When it comes to external part features, CNC milling can sometimes compete, unless the job calls for a simple slot or a series of slots and the piece can be magazine-loaded. In that case, "by the time the workpiece is loaded into and ejected from a CNC mill, broaching is already finished and moving to the next piece," Roschman said.

V W Broaching Service has more than 60 horizontal, vertical and continuous-chain broaching machines. The company also utilizes vertical shapers and wire EDMs. With this capacity, the company can broach nearly any size part made of almost any material, Espy said.

He added that the company does high-volume production work as well as single-part runs. "We can create complex forms using modular tooling and multistage operations," Espy said. While internal and external broaching are the company's bread-and-butter, V W Broaching also does complex specialty broaching, such as spiral, blind-hole, straddle and pot broaching.

Horizontal broaching was the first broaching method developed and is still the most common way to cut internal shapes and forms, such as keyways. The company has several of these machines, each distinguished by its length of cut, which is a direct function of its total stroke and tonnage. In a typical horizontal broaching of an internal feature, the workpiece is fixtured to a base plate and the cutting tool is pulled through the piece. "We can cut up to 84" in length using one pass, with a maximum of 25 tons," Hanna said.

On a recent project, Hanna and his team used an old Colonial horizontal machine to broach an internal spline on a 24"-dia. stainless steel ball valve. While this valve is large, the company can broach larger products, including a 48"-dia. valve that required removal of the machine's front panel to set up the workpiece.

"The internal spline on that valve takes about 10 seconds to complete," Hanna said. "If that were on a gear-shaping machine, it might take a couple hours."

The company uses many different setups on its vertical broaching machines. Typically, the ram moves past the workpiece, carrying its broaching tools mounted in holders, and the part is secured in a fixture using hydraulic or mechanical clamps.

V W Broaching produces sprags, the clutch components that allow a flywheel to turn in one direction but not in the reverse direction. An operator of a vertical broaching machine, in a pull-down configuration, feeds bar stock into a broach, pulls down the ram and produces 24 sprags at a time in less than 4 seconds. In one shift, the company produces about 12,000 of these components.

A high-speed broaching method often employed at V W Broaching Service is continuous-chain broaching, which Espy refers to as "a train." This train consists of a series of workpieces mounted to "cars" that enter an enclosed cutting envelope. The workpiece is chain-pulled past the cutters, each of which removes a small amount of stock. One recent job called for a deep slot to be cut into the tip of a part, reaching the required 3⁄8" depth with the help of 18 modular cutting tools.

This method is geared to high-volume production of external features and is extremely fast and efficient, Espy said. Another benefit is that it does not require a one-piece, solid broach; instead it uses smaller, modular cutting tools. "Instead of ordering a $10,000 broach and waiting weeks for it, we can make this tooling package in-house for a nominal fee and be up and running that day," Espy said.

Modular tooling is appropriate for simple, external forms like slots and notches. However, when cutting complex internal forms such as irregular shapes and involute splines, the only option is a solid, one-piece broach.

Other MachinesThe company often looks for ways to save its customers money and decrease cycle times, Roschman said. Sometimes, grinding a broach is not cost-effective, he added. "If we are talking about onesies and twosies, and it has a straight-sided shape, we can do it with our vertical shapers," Roschman said.

While many general machine shops no longer have vertical shapers, V W Broaching uses several of them as well as keyseaters, which generate about 15 percent of the company's annual income. A shaper uses a single-point cutter to progressively remove material in multiple passes. "The vertical shaper is very versatile. It can do very large and heavy parts, and it can do very small parts. We don't need to make an expensive broach to get the job done," Hanna said.

For example, the company used a vertical shaper to generate an internal spline. The part was machined in two passes, a rough and a finish pass, and the tolerance was 0.008".

"We hold it to a plus, but never a minus tolerance," Espy said.

The company also wire EDMs parts when the application is appropriate. V W's EDMs are sequestered in a temperature- and humidity-controlled room. EDMed parts are designed using Esprit CAD software.

The wire EDM department is just part of V W's plan to add machining capacity and expand into secondary operations, including, grudgingly, CNC milling. About 90 percent of all jobs are done without the need for subcontracting, but Roschman would like to improve on that figure.

It is no secret, he said, that these are challenging times for broaching companies, as margins are tighter, new technologies are entering the marketplace and engineers and part designers are creating products that do not require broaching. Because of that, Roschman said the company has to continue to increase market share and offer more capabilities.

Within the last 10 years, the company acquired Broach and Fixture Renewal Service, Harvey, Ill., High Speed Broaching Co., Franklin Park, Ill., and Hennig Broach and Tool Co. Inc., Thornton, Ill., which brought into the company more experienced staff and equipment. The Hennig acquisition, which was the most recent, enables V W Broaching to provide an entire new line of stock keyway broaches. These acquired companies were renamed V W Broaching Service, and now operate under the corporate banner, helping to carry the company into the future. "There are not many broaching companies who make their own broaches on-site anymore," Roschman said. "That is why the acquisitions were so important to the company."

For more information about V W Broaching Service Inc., call (800) 966-6052 or visit www.vwbroach ing.com. CTE

Broaching's bright future?

A broach is CNC-sharpened to help the tool produce parts with tight tolerances.