Tips for trouble-free tapping

Tips for trouble-free tapping

Make a quick, quality thread without breaking the tap.

In this article I will discuss the tapping operation. There are a number of factors to take into consideration for trouble-free tapping. I will not discuss tapered threads such as those used for pipe threads, but rather straight threads in blind or through holes. My goal is to make a quality thread quickly without breaking the tap. A tap that breaks in the hole can be a significant hit to profitability. Taps are made of hard material. There are gadgets available to extract a broken tap, but I have never had any luck with them, and I've been playing this game for 50 years. There are two sure alternatives, remove a broken tap with an EDM machine or scrap the part.

Images courtesy of B. Taylor

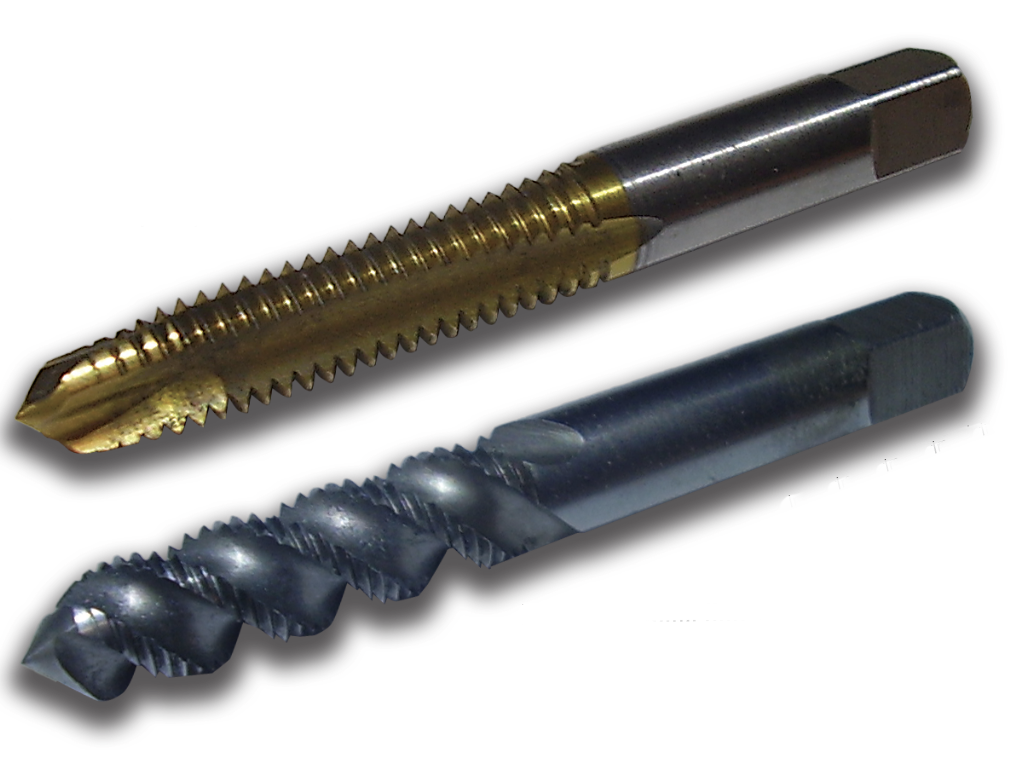

For trouble-free tapping, it's about torque applied to the tap versus the tensile strength of the tap. Too much torque and the tap breaks. Taps that have a helix on the cutting edges will shear the chip and cause it to curl away from the cut. The shearing action reduces the applied torque to cut. The curl causes the chip to move away from the cut, not ball up between the tap and the workpiece, and jam the process. There are two styles of taps that have a helix on the cutting edges. Spiral point taps cause the chips to spiral ahead of the tap and are good for through holes. Spiral flute taps cause the chips to spiral up the flutes of the tap and are good for blind holes. Spiral point taps generally have a larger cross-sectional area and are thus stronger. They are also self-cleaning. Running the tap into the hole pushes the chips through the hole, and, on retraction, the chips are left behind. With spiral flute taps the chips will wrap around the tap and must be cleaned away after each hole is tapped.

Figure one shows a spiral point tap and figure 2 shows a spiral flute tap. If you need to bottom tap a blind hole, spiral flute bottoming taps are available. When bottom tapping, first use a spiral flute tap with a chamfered end, then the bottoming tap.

The tap drill size is very important as the thickness of the chip removed by the tap impacts the torque to tap. It is an exponential factor. Double the chip thickness the torque goes up by a factor of 4. So, use the biggest tap drill possible for the thread being made.

The fluid used for tapping is also very important. The fluid used can be the difference between success and failure. A good fluid will cut the torque required and produce an excellent surface finish. My experience is that all fluids that have water in the mix cause problems. There are a number of specialty tapping fluids on the market. Tap Magic products work for me.

Finally, there is cutting speed. Slower is faster. As the cutting speed goes up, the amount of metal removed per minute goes up and so the cutting torque goes up. Unless you are making a million parts, the few seconds it takes to thread a hole at a slow speed are not going to affect the bottom line much — especially if a tap breaks in an expensive part.

Happy tapping.