Turning Plus

Turning Plus

Vertical turning systems now integrate functions like grinding, combining precision and automation to handle tight tolerances in electric vehicles and jet engines.

When surveying the latest products that offer vertical turning, shops will see that much of the recent progress has not come in the form of improvements to the turning process itself. Instead, the news has been mostly about what can now be packaged with vertical turning. This includes additional machining functions that have traditionally required separate systems, as well as automated part-handling options that minimize the need for human intervention in the manufacturing process.

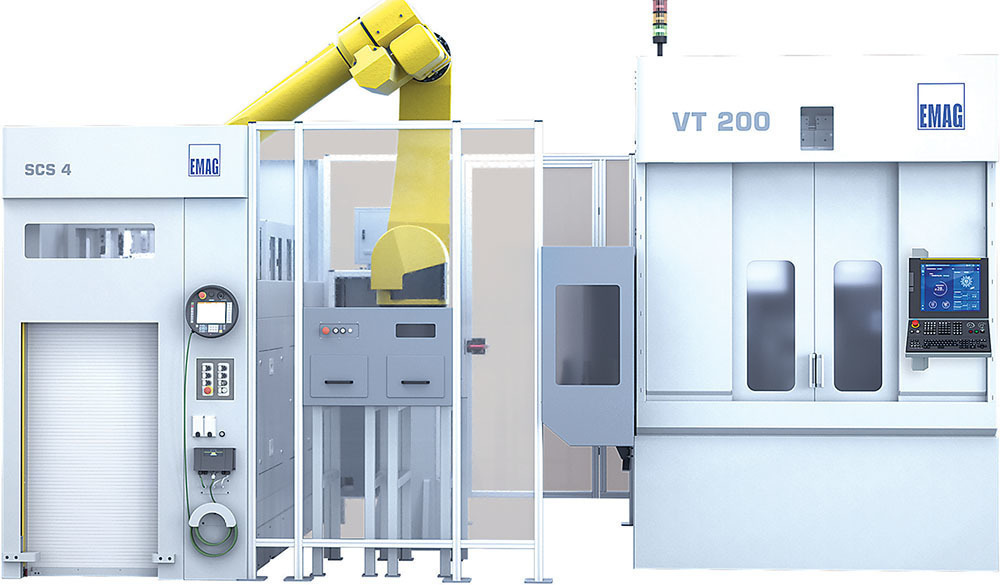

One example of the type of process integration taking place today is the combination of vertical turning and grinding capabilities in a single machine, noted Jeremy Elder, manager of sales and key accounts at EMAG LLC, a machine tool manufacturer in Farmington Hills, Michigan. Elder pointed out that these combo machines meet the needs of shops making parts with finished ground surfaces. "Having a single machine that's able to do your hard turning and grinding in the same clamping adds to the accuracy and reliability of your process," he said.

According to Elder, these machines are popular with manufacturers of rotor shafts and other components for electric vehicles that have demanding accuracy requirements. "All electric vehicle rotor shafts have very tight tolerances on the journals and diameters because (manufacturers) are worried about road noise," he explained. "The tighter that tolerance, the less noise that component would make in the system. So we've had a large number of requests for making those types of components that require a hard-turned ground surface. That's where these machines really shine."

In addition to EV manufacturers, Elder reported that combination turning-and-grinding machines have drawn interest from makers of jet engine motors that require tight tolerances, as well as tractor manufacturers that need to produce highly accurate gear features.

Besides improved accuracy, Elder pointed out that combo machines are easier for shop personnel to maintain than systems that do the same thing but consist of a separate turning lathe and grinder, as well as a robot working between them. In addition, they often take up less space than the conventional alternative. "As floor space in the industry becomes more important, a machine with combination capabilities and a smaller footprint can be beneficial to the facility," he noted.

As for cost, the purchase price of a combo turning-and-grinding machine is similar to that of a conventional lathe-grinder-robot setup, according to Elder. "You might think it would be less," he said. "But because of the accuracy a lot of these combination machines need to hold, they have a lot of extra hardware" — including glass scales on all axes, which may be lacking in standard lathes, as well as heavier bearings and heavier vibration-dampening mineral bases.

More Combinations

Other combo options on the market offer turning, grinding and milling capabilities. An example of this type of system is the DMU 210 FD mill-turn portal machine with integrated grinding, sold by DMG MORI USA in Hoffman Estates, Illinois. Like combination turning-and-grinding machines, the DMU 210 FD makes it unnecessary to move parts from machine to machine to complete different operations. In the case of a machine offering three machining functions, this eliminates errors caused by setting up parts three separate times for different machining processes, noted John McDonald, vice president of technology at DMG Mori USA.

McDonald added that the DMU 210 FD occupies roughly the same amount of floor space as a large vertical turning lathe, which could save users the expense of expanding their facilities to accommodate a separate VTL, milling machine and grinder. And while this machine is "probably a little bit more expensive" than a traditional VTL, he pointed out that combining multiple functions in one machine also reduces the need for machine-tending personnel at a time when shops are having a hard time finding workers.

Another variation on the combo theme are machines that offer vertical turning as well as gear-cutting capabilities. Among these are the VTM-1200YB and VTM-2000YB from Okuma America Corp. in Charlotte, North Carolina. According to Okuma lathe product specialist David Fischer, these machines feature upgrades that include a higher-power (50 hp) milling spindle, a faster tool changer, and heavy-duty roller guideways that took the place of box guideways to accommodate multitasking.

After these changes were made to the machines, Okuma added a package of capabilities that includes gear hobbing and skiving, as well as profile milling of gear teeth. Fischer said the integrated gear-cutting package can reduce the handling of large parts and eliminate the need to send them out for additional machining. For hobbing and skiving, the VTM-1200YB and VTM-2000YB synchronize their turning and milling spindles to cut the gear, he explained.

Bucking the Trend

Although combining two or more functions in a single system is desirable in many machining scenarios, that's not always the case. For instance, Fischer points to aerospace applications that require removal of relatively large amounts of difficult-to-machine materials. For these situations, he reported, many customers "were buying our VTM, which can do (vertical) turning and milling, but they never used the milling." These customers, he said, "wanted tool-changing and turning only."

So Okuma came out with a large vertical CNC lathe called the VT1000EX. Equipped with a tool changer but no milling capability, Fischer said this machine is aimed primarily at the aerospace industry but is suitable for any application "where you're dealing with difficult materials and you have a lot of material to remove."

The VT1000EX is "a beast of a machine," he noted, featuring Z-axis thrust of 24.6 kN, X-axis thrust of 27.3 kN, and 5,000 N·m of spindle torque. In some applications involving the machining of nickel-based alloys, the VT1000EX has cut cycle times by more than 50%, he reported. And with the tool changer and a number of backup tools, he added, the machine can run for long periods of time without operator intervention.

Automation Integration

Regardless of whether vertical turning is combined with other machining functions, it's becoming more common to add some form of automation to the process. "Automation is the wave of the future and a key to increasing the productivity of any machine," noted Rick Collins, senior applications engineer at Mazak Corp., a machine manufacturer in Florence, Kentucky.

On the downside, Collins pointed out that robots can break down and sometimes perform part-handling jobs more slowly than a diligent operator. On the other hand, he noted, robots are very consistent in how long they take to do a job and in part placement. In addition, "they don't take breaks like operators do, nor do they get sick or take a vacation," he said, adding that they also free up operators to perform other tasks.

According to Collins, working with robotics is becoming easier for shop floor personnel, thanks to more menu-driven setup and programming, as well as less-sophisticated language to learn in order to perform these tasks. Once a robot is paired with a machine, it knows where to pick up parts and place them in the machine, as well as where to come back for the parts and place them after machining.

For easier robotic and human machine control and part handling in setups with two machines, Mazak offers "right-hand" and "left-hand" vertical turning machines that are basically mirror images of each other. There's no difference between the two in terms of functioning or capabilities, but right-hand machines have the chuck on the left side and the turret on the right side while the opposite is true for lefthand machines, Collins explained.

Right- and left-hand machines can be placed side by side, in an L shape or facing each other. All these arrangements produce an ergonomic advantage, Collins noted, because the doors and controls are closer together, which means an operator doesn't have to move as far when running the two machines. It's also an advantage when implementing automation, he added, making it easier for a single robot to service both machines.

Automation possibilities for machines that offer vertical turning include optional systems that load and unload part-holding pallets to keep unattended machines running. An example is DMG Mori's PH Cell 500 automation system, which works with the company's DMU 65 (FD) monoBLOCK 2nd Generation 5-axis machining center that offers both milling and turning. Capable of handling up to 32 pallets and 500 kg transfer weight, the PH Cell 500 can be added to machines already in the field whenever users decide they're ready for automated pallet handling, McDonald noted.

Are there any good reasons for machine shops not to opt for process integration and automation? "I don't see any downside," Mc-Donald said. "Of course, they have to have the skill level to be able to manage a more complex machine, but that will come with learning and experience."`