Automation Systems

Contact Details

Automation boosts shop's productivity 41%

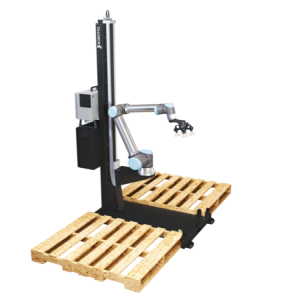

The sixth episode of this Cobotics Corner video series demonstrates the use of a Universal Robots UR5e arm with a Schunk three-finger gripper loading and unloading a Haas Automation SL-20 CNC machine. This automation solution reportedly helped increase productivity by 41%, according to Fusion OEM.