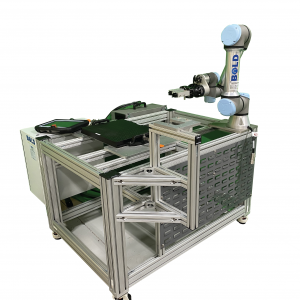

Cobotics Corner Case Study: Increasing productivity 32%

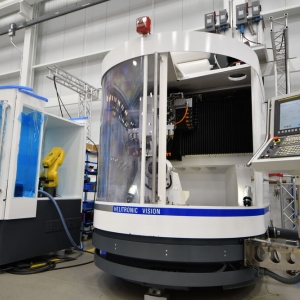

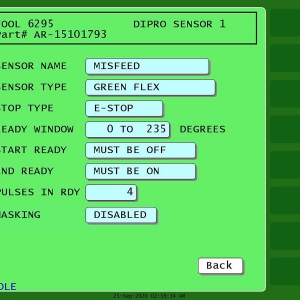

Watch a Cobotics Corner demonstration that helped increase productivity by 32% using a Universal Robots UR5e arm with a Robotiq dual parallel servogripper on a 2018 Haas Automation VF-2SS CNC machine, according to Fusion OEM. For more information about systems integration services, please contact Fusion OEM at [email protected] or visit www.fusionoem.com.