Automation Systems

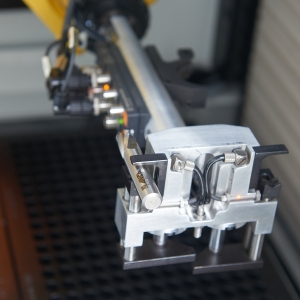

CNC machine tending with Haas VF-2SS & UR10e

Watch a Cobotics Corner demonstration that helped increase productivity by 43% using a Universal Robots UR10e arm with a Robotiq dual parallel servogripper on a 2018 Haas VF-2SS CNC machine, according to Fusion OEM. For more information about systems integration services, please contact Fusion OEM at [email protected] or visit www.fusionoem.com.