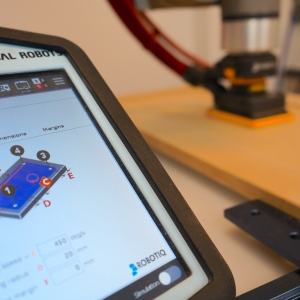

Automation Systems

Presenting an automated coolant delivery system

Precision Tool Technologies Inc., Brainerd, Minnesota, developed the FullShop automated coolant delivery system to eliminate manually monitoring and replenishing coolant so that the shop could enable unattended machining. This video, presented as a video supplement to CTE's May 2020 Productive Times article, offers a quick overview of the company's FullShop system, which monitors coolant usage at a machine tool sump and automatically replenishes coolant before it runs low.