‘Toolbox of Technology’ for Grinding Machines

‘Toolbox of Technology’ for Grinding Machines

From 3D simulation software to LaserPlus, an in-process measurement system, to RoboTeach, which makes robotic loaders accessible and easy to program – ANCA has been building a toolbox of technology for our customers to reap the benefits of automation and Industry 4.0.

From 3D simulation software to LaserPlus, an in-process measurement system, to RoboTeach, which makes robotic loaders accessible and easy to program – ANCA has been building a toolbox of technology for our customers to reap the benefits of automation and Industry 4.0.

Russell Riddiford, president, ANCA Machine Tools said: "We are happily experiencing a very strong market in the America's at present. Customers are reporting record level orders and with the tax incentives driving significant growth in the US manufacturing sector – sentiment is at an all-time high. The challenge of meeting the demand in boom times is how to scale up production without incurring huge infrastructure costs. Automation is proving to be by far the best solution for tool manufacturers as it beefs up capacity and the cost of that investment is quickly realized with the increased volumes. For example, one customer we helped by developing a dual robot grinding cell managed to reduce production costs by 50% through lights out manufacturing.

"We are working closely with our customers to help them realize the benefits of automation and have our own AR300 robot loader on the stand. The first production ready model and I am confident our customers will love the cost-effective technology that offers huge efficiency opportunities," Russell concluded.

Simulation and 3D modelling tools offer a way for businesses to measure and plan without requiring the use of materials outside the digital environment.

Simulation:

-

reduces the learning curve for new operators

-

provides precise design simulation with a full-range of compensation and adjustment options

-

designing the tool digitally achieves significant reductions in tool waste as there is no need to perfect the tool by grinding numerous versions

For example, Scripting, a simple programming language created specifically to automate tasks within ANCA application software, can be used to automate most tool design tasks, such as entering parameter values or drawing line/arc elements in 2D editors. It can also be used to create sophisticated fully-featured custom tool wizards with graphical user interfaces. This means less work for the operator, knowledge retention through capturing design and process intelligence and reduced programming and setup time.

"In the past, the simulation was in my head and that's true of many manual cutter grinders. You have an idea of what you want, and after making the tool you hope it is produced to look like what you've been dreaming about. ANCA's simulation software allows us to create the tool with all the given parameters and see what the finished tool will look like. That combined with being able to program off machine has revolutionized how we make cutting tools," said Alfred Lyon, cutting tool supervisor at AB Tools.

Tool manufacturers are applying cloud technology - ANCA's Management Suite/Redax - to monitor machines and production in real time, allowing better informed decisions to be made at the time when they will have the most impact ability to remotely schedule, control and monitor networked machines so factories today can access real-time information, providing enhanced visibility and greater control over manufacturing data.

"With the installation of the Production and machine monitoring software REDAX, we have expanded the possibilities of data analysis more than ever. Thanks to this excellent software, we can track our production planning more accurately. It means we can track the current status and activity of our machines and use the data to plan our production processes," said Tarık Öztürk, production manager at Turcar.

Data analytics are already a core component of many tool manufacturers operations. The use of advanced analytics is being applied end-to-end across the production and supply chain activity. This is providing valuable insights into areas including production levels,

inventory, available capacity, quality levels, order status to optimize manufacturing processes, predict machine failures before they happen and ensuring production uptime is maximized.

About 70% of ANCA customers buy machines with robotic functionality. Far from a nice-to-have add on, CNC machines now come with operator panels that provide in-built control over both the grinding software and the robotics function opening the door to greater automation efficiencies.

More recent trends are to include dual robots within a single machine - a market first from ANCA - allowing more complex grinding to be completed with ease and improving overall productivity. The primary robot performs principle automation tasks like changing wheel packs, part loading and pallet management, while the second robot can perform a range of functions such as part washing, metrology, part identification and laser etching to enhance flexibility and productivity.

RFID technology is used in grinding to increase the flexibility of tool programming, automate the tool loading process and remove the need for operators to program individual loader pallet pockets to a specific tool, enabling businesses to run overnight and weekends 'lights out'.

Tarık Production Manager at Turcar continued, "There are a lot of advantages of the RoboMate. The biggest advantage is that instead of a machine standing idle, automation means production can be significantly increased. Process accuracy is another advantage of this technology and the accurate surface finish is why our customers choose to work with us."

With increasingly demanding requirements for precision when it comes to tool manufacturing, the challenge has been to grind tools accurately, while still maintaining a high level of productivity and reducing waste. Enter automated measuring solutions that can inspect and measure both in process and offline.

As an example, Zoller measurement technology has been integrated with ANCA software allowing tools to be ground, measured and validated remotely to ensure they are of the right quality to create top-grade parts. The results are automatically sent to the ANCA machine to correct any discovered errors, ensuring 100% tool accuracy.

"The ability of the Zoller Genius to network directly into the ANCA machine has helped us be more competitive in the marketplace because we're able to give customers exactly what they're asking for, with diameters down to the millionths and cutting geometries that are plus or minus one degree," Jordan Armitage, manufacturing manager at California Tool and Cutter.

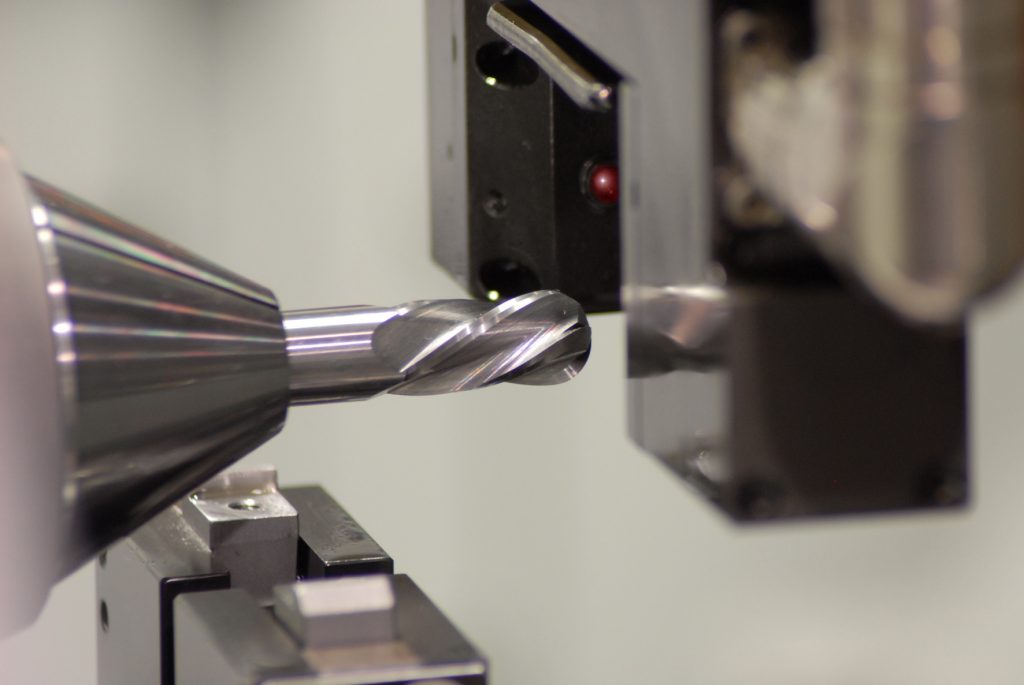

In process measurements like ANCA's LaserPlus, allow the measurement of tool geometries to tolerances of 2 microns or less without removing the tool from the grinder, saving time in the manufacturing process and ensuring maximum accuracy in measurement.

"We have a very strong brand name and we have been making excellent tools since 1996," said Benchmark Carbide owner Paul St. Louis. "But our customers are expecting more from us in terms of tolerances than ever before. Automation plus ANCA's on-machine laser checking system LaserPlus has allowed us to make sure every tool is reproduced to exactly the same specs every time, while operating unattended seven days a week. The better job we do, the more business we can get."

For many years surface marking required screen printing or engraving. These processes were typically invasive, expensive, and non-permanent. In its place, laser marking offers the factory of the future a way to mark the surface of goods without the drawbacks of traditional processes. Already it has been adopted in many businesses and recognized as an essential component in the factory of the future.