Machines/CNC

Outpace the Competition with Okuma Automation Solutions

Searching for skilled labor and ways to increase overall efficiency and productivity has just gotten much easier with Okuma’s automation solutions. Whether you’re looking to integrate automation on your existing machine or need a machine that comes fully equipped, Okuma can help you outpace the competition by using state-of-the-art technology. Automation solution options include automatic tool changers, automatic pallet changers, gantry loaders, external conveyor belts and robotic cells. Learn more about Okuma’s automation solutions in this video.

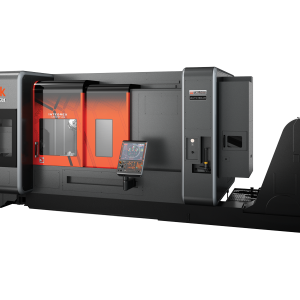

Mazak HQR-250MSY Multi-Tasking Turning Center

The Mazak HQR-250MSY Multi-Tasking turning center features a highly productive twin-spindle, twin-turret configuration for unequaled part processing opportunities and high-volume throughput. Watch as it demonstrates its ability to machine parts complete – from raw material to finished part – in a single setup.

Learn more about this highly productive machine here: https://www.mazakusa.com/machines/hqr-250msy/

Contact Details

What's the secret to over 60 years of manufacturing success? Finding the right partners.

For over 60 years Cox Manufacturing has been serving a wide variety of industries with high-quality machining services. Company Owner and President, Bill Cox standardized his machines on FANUC CNCs. This strategy helped the company thrive and outperform industry peers.

For more information visit us at https://www.fanucamerica.com/products/cnc