Full-diameter slotting of steel

ProvenCut recipe 551 shows how to achieve a high material removal rate while maintaining a reliable cut using a light-duty machine with a 6.35 mm (0.25") endmill to slot 4140 alloy steel.

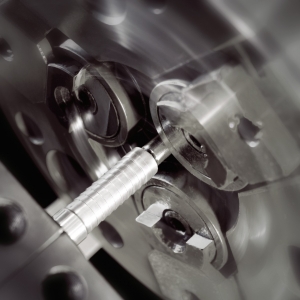

The video, a supplement to our Shop Operations column in the June 2020 issue of Cutting Tool Engineering, shows the slotting operation in action. To learn more about when full-diameter steel slotting is the only option, read the related Shop Operations column.