Machines/CNC

Contact Details

Contact Details

Contact Details

CTE Playlist

A CTE featured video playlist.

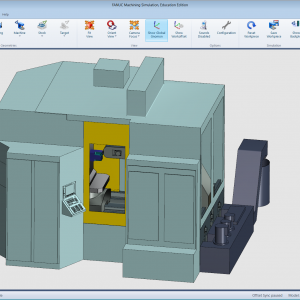

Hybrid machining demos

View video presentations by ModuleWorks and Open Mind Technologies USA to learn more about hybrid manufacturing. The videos are presented here as a video supplement to the hybrid machining article in the October 2020 issue of Cutting Tool Engineering.