Turning

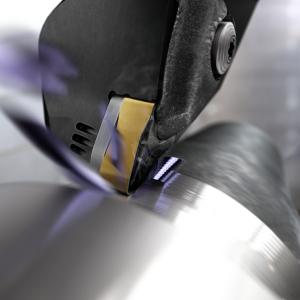

AddMultiTurn – Front turning, back turning, profiling, and face turning with ONE SINGLE TOOL

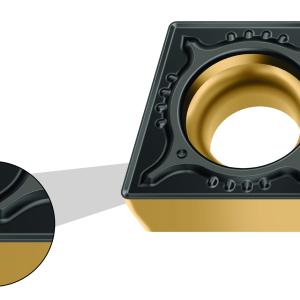

AddMultiTurn – Front turning, back turning, profiling, and face turning with ONE SINGLE TOOL. Tungaloy's 6-corner inserts with the company's ultra-secure Y-PRISM clamping design for high versatility, economy, and productivity. Available in 80° or 35° corner angle.