API launches independent CMM calibration business

API launches independent CMM calibration business

API Services has added coordinate measuring machine calibration to its portfolio of machine tool, industrial robot and laser tracker calibration services. API offers both a standard CMM certification and a premium CMM calibration service to original OEM CMM specifications.

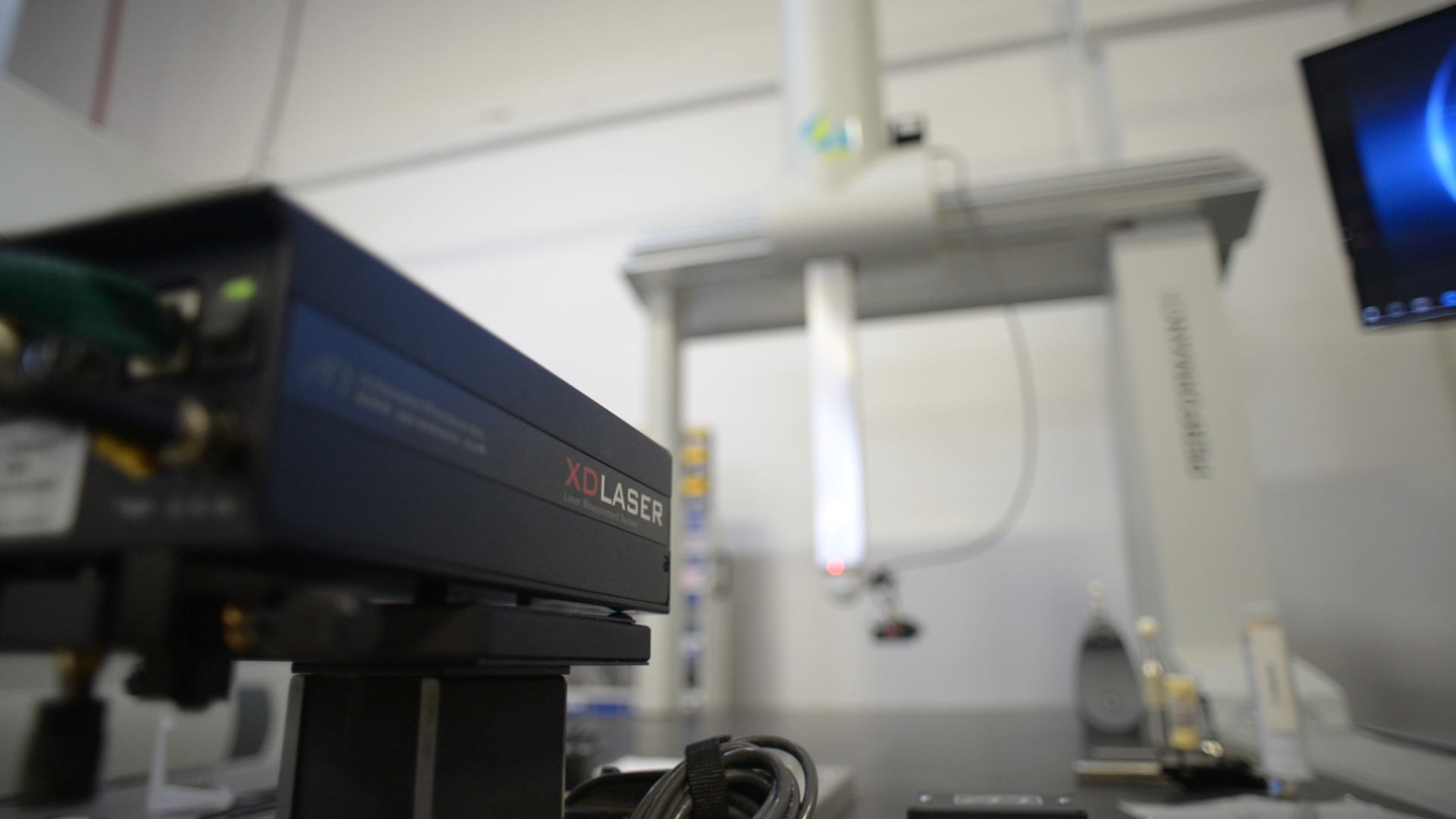

API Services has added coordinate measuring machine calibration to its portfolio of machine tool, industrial robot and laser tracker calibration services. API offers both a standard CMM certification and a premium CMM calibration service to original OEM CMM specifications. The latter includes a full 21 parameter error-map created using the API XD laser interferometer and 6 degrees of freedom (6DoF) calibration. Calibration reports include "before" and "after" information.

API's CMM calibration service allows users of all popular CMM brands to maintain their investment by contracting API, as an independent third-party provider, to calibrate CMMs to OEM or better specifications in accordance with ISO 10360-2.

API's CMM service uses a "revolutionary" software utility, which allows the calibration of all CMMs by importing, reading and modifying the original CMM error maps, regardless of whether the map is located in the CMM controller or in the CMM metrology software.

API offers highly skilled calibration technicians and the award-winning XD 6DoF laser interferometer, which measures all 21 errors of the CMM in a single setup. In addition, all CMMs are evaluated using an "acceptance check" fixture, based upon a rigid body, with high-precision calibrated measuring standards.

API is accredited to ISO/IEC 17025:2017, ANSI/NCSL Z540-1-1994, ISO 9001 and AS9100 with all equipment calibrated and traceable through NIST.