Contain the mess for cleaner, more precise grinding

Contain the mess for cleaner, more precise grinding

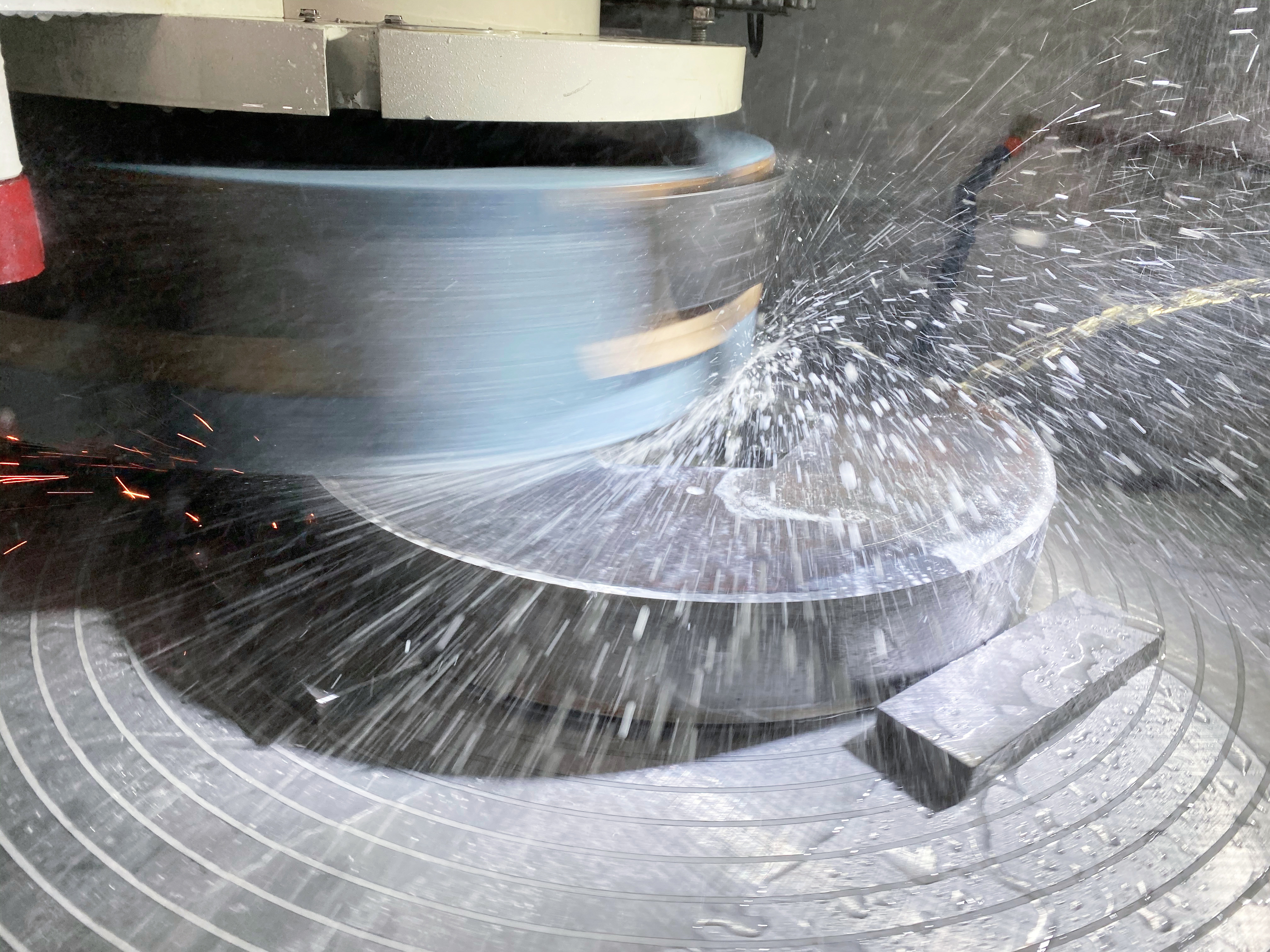

Advanced precision rotary units are designed to minimize surface grinding mess and completely contain any debris.

Today's advanced surface grinders work to contain the cloudy haze of dust, swarf, and debris generated during the grinding process. The grinders work by minimizing the amount of material that must be removed to achieve very precise tolerances, and incorporate shrouds, air misting, and cooling filtration systems that contain the mess almost entirely.

"Many people know they are in a shop with a conventional surface grinder as soon as they walk in the door because there is a unique smell due to the breakdown of the abrasive, combined with the burning of the material. It is also not uncommon to see a cloud of dust over the grinding area," said Erik Lawson, engineering manager at Winona, MN-based DCM Tech, a designer and builder of industrial rotary surface grinders.

In precision metalworking shops, grinding the surface of parts is often required to achieve certain specifications for size, tolerance, flatness, or surface condition. Regardless of the reason, traditional surface grinders are notoriously messy – producing dust, debris, and swarf, which is a combination of the material removed and the consumed abrasive.

However, in precision machine shops today there is increasingly less tolerance for excessive grinding mess. Machine shops prefer tidy operations and so are increasingly searching for more modern, automated surface grinders that are easier to operate, provide much more precise grinding, and do so while containing the debris.

Times have changed

A decade or two ago, a messy, dusty shop floor may have been acceptable, but not today. Precision machine shops have evolved and now both customers and operators have much higher expectations for tidiness, according to Lawson.

"For customers, a messy shop floor can indicate a lack of attention to detail and raise questions about the ability to be precise. Shop operators do not want to work in a cloud of dust and swarf all day, go home dirty, and have their family smell it on their clothes," said Lawson. In the past, he said, machine shops may have swept their floors once a week or, at best, once a day.

Today, many machine shops take pride in presenting an extremely clean work environment. Since the grinding process is inherently messy, however, the first key to achieving a clean shop while meeting all quality criteria is grinding to spec without overgrinding.

"Automated, precision grinders minimize mess because the machine only removes the minimal amount of material and so prevents overgrinding, which generates excess dust and debris for no real purpose," said Lawson. "On top of that, some material is quite valuable, so overgrinding can be costly."

Machine shops primarily utilize surface grinders with a reciprocating table and a horizontal spindle that turns the grinding wheel. Reciprocating table grinders are precise but have a slow material removal rate and require multiple passes. Traditional rotary surface grinders are a faster option but can be problematic in the hands of less experienced operators. With limited control of spindle speeds as well as manual controls, the equipment requires sophisticated operators that can factor in complex calculations, and considerable expertise and experience are required.

Although both types of conventional surface grinders can be found in many shops, they typically have an open configuration, which allows dust and debris to escape the machine and become airborne.

In contrast, modern vertical spindle, rotary table surface grinders have a table that rotates with the workpiece held firmly in place underneath a vertical spindle. The grinding is not performed by the peripheral edge of the wheel, but by the entire diameter of the abrasive surface, which facilitates grinding performance and consistency.

"The less material that is removed while meeting all specs, the less debris that goes into the air or gets into the coolant," said Lawson.

Today, surface grinders like DCM Tech's IG 282 SD are also designed with much more advanced sensors and controls that automatically maintain very tight tolerances, removing material down to within one ten-thousandth of an inch of the final thickness. This can prevent overgrinding and enable operators to be much more intentional about how much material they would like to remove from each part.

When it is essential to contain debris to avoid a mess, selecting such an advanced rotary unit with an integrated shroud is also important. "The shroud, which is a sliding door with a built-in window for viewing the process, encloses the grinding area," he said. He added that a fully enclosed shroud also reduces the noise produced by the machine.

In addition to a shroud, grinders like the IG series provide an integral air mist collection system that draws particulate from the air and moves it away from the operator to enhance the cleanliness and safety of the work environment.

Because of the importance of clean coolant when grinding, IG grinders provide through-spindle and external coolant flow, as well as a self-contained recirculating filtration system with a 3μm roll style paper pre-filter and 5μm in-line canister filter.

The most advanced units even offer programmed features that allow the machine to automatically rinse parts when grinding is complete, which is what a good operator would do.

"The rinse clears the debris from the tooling mating surfaces, so there is no problem loading the next part. This is very advantageous, particularly in automated settings where there is no operator on the machine," he said.

Although "messy" and "grinders" have been synonymous for decades, modern design improvements provide machine shops with much cleaner, high-performance options. Today, modern rotary surface grinders can be configured with sophisticated, automated features that make the messiest grinding operations a thing of the past.