Engine plant reduces power, water consumption by about 30%

Engine plant reduces power, water consumption by about 30%

At the BWM Group's engine plant in Steyr (Austria), in a reference project accompanied by the Technical University of Vienna, Ecoclean Monschau has significantly raised the energy efficiency of a flexible EcoCFlex Classic robot cell that had been in service for several years. The system's electric power and water consumption were each cut by around 30 percent. These energy efficiency measures are now intended to be implemented on another 95 systems of the same type installed at various sites throughout Europe and Asia.

At the BWM Group's engine plant in Steyr (Austria), in a reference project accompanied by the Technical University of Vienna, Ecoclean Monschau has significantly raised the energy efficiency of a flexible EcoCFlex Classic robot cell that had been in service for several years. The system's electric power and water consumption were each cut by around 30 percent. These energy efficiency measures are now intended to be implemented on another 95 systems of the same type installed at various sites throughout Europe and Asia.

The BMW Group has been using EcoCFlex Classic robot cells made by Ecoclean Monschau for around 12 years in several of their factories to debur and clean engine parts such as, e.g., cylinder heads for diverse car models. At the Steyr (Austria) engine plant, 30 first-generation units of this flexible cleaning machine are in use. Now as before, their cleaning performance is reportedly beyond reproach. However, in terms of energy efficiency – a parameter closely monitored by the BMW Group – the systems are no longer up to today's standards. Their water consumption in particular has proved too high. BMW Steyr, therefore, contacted the equipment manufacturer, inquiring if and how the machines could be energetically optimized.

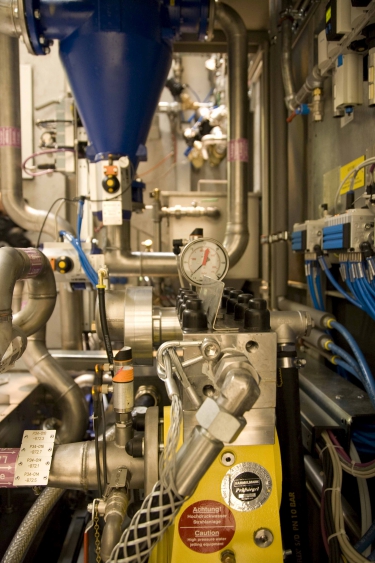

Energy efficiency measures yielded an approximately 30 percent reduction in the electric power and water consumption of an EcoCFlex Classic robot cell that had been in service for several years. Photos: Ecoclean

Potential analysis revealed saving options

Ecoclean has developed a potential analysis especially for this type of task. In their investigation, the equipment maker's service staff will focus on factors such as the water consumption, cleaning agent input, electricity demand of power drawing equipment, and the consumption of compressed air. Flow measurements revealed that large quantities of vapour were extracted from the cleaning cell, causing the machine's elevated water consumption. Furthermore, the analysis identified a major electricity saving potential in operation of the feed pumps.

Small measures, large effect: 30 percent savings

One measure taken to reduce the water consumption involved changes on the air control dampers. Moreover, the flow velocities inside the system were adapted via a modified fan control regime, resulting in substantially less vapour getting discharged. In the case of the booster pump, a variable-frequency drive unit now provides demand-based control and hence, energy savings.

Thanks to these relatively minor improvement measures the system's overall electric power consumption was cut by around 30 percent. Savings of the same magnitude were achieved at the level of the water consumption, and are additionally reflected in a reduced need for cleaning chemicals.

Due to the integration of a variable-frequency drive unit, the booster pump is now controlled as a function of demand so that the unit uses much less energy.

An independently validated reference project

The measures were initially carried out on a system installed in the Steyr/Austria-based engine plant. For an objective evaluation of results, the Technical University of Vienna accompanied the reference project with extensive pre- and post-optimization measurements. Depending on the availability of national or regional programs, the unbiased attestation of this successful efficiency improvement may support applications for public funding.