Mastercam’s 2018 Wildest Parts competition winners

Mastercam’s 2018 Wildest Parts competition winners

CNC Software Inc. has announced the winners of the 2017-2018 Wildest Parts competition. The company develops the industry leading CAD/CAM software, Mastercam, and holds the Wildest Parts Competition each year to encourage student interest and participation in manufacturing. The competition is open to students at the secondary and postsecondary levels to create parts demonstrating creativity and technical skill using Mastercam.

CNC Software Inc. has announced the winners of the 2017-2018 Wildest Parts competition. The company develops the industry leading CAD/CAM software, Mastercam, and holds the Wildest Parts Competition each year to encourage student interest and participation in manufacturing. The competition is open to students at the secondary and postsecondary levels to create parts demonstrating creativity and technical skill using Mastercam.

In the Secondary Division, Caelen DeVall from Hamilton High School submitted a spiral didgeridoo, which is a large wind instrument, typically from 1 to 2 meters in length (which is long and hard to transport). DeVall plays the didgeridoo and owns one, but he wanted a more compact instrument to bring around with him. So, his idea was to design a more efficiently spaced didgeridoo that has been wrapped to fit into a smaller space and function as an instrument. He applied Mastercam's Dynamic OptiRough toolpath for the inside of the instrument and applied both rough and finish toolpaths for the outside. Grayson Weber from Capital High School placed 2nd with a fly tying kit, and Zane King from Capital High School placed 3rd with his submission of dirt bike pegs.

Caelen DeVall, a student at Hamilton High School, won 1st place in the secondary division for producing this spiral didgeridoo. His instructor is Brent Holmes.

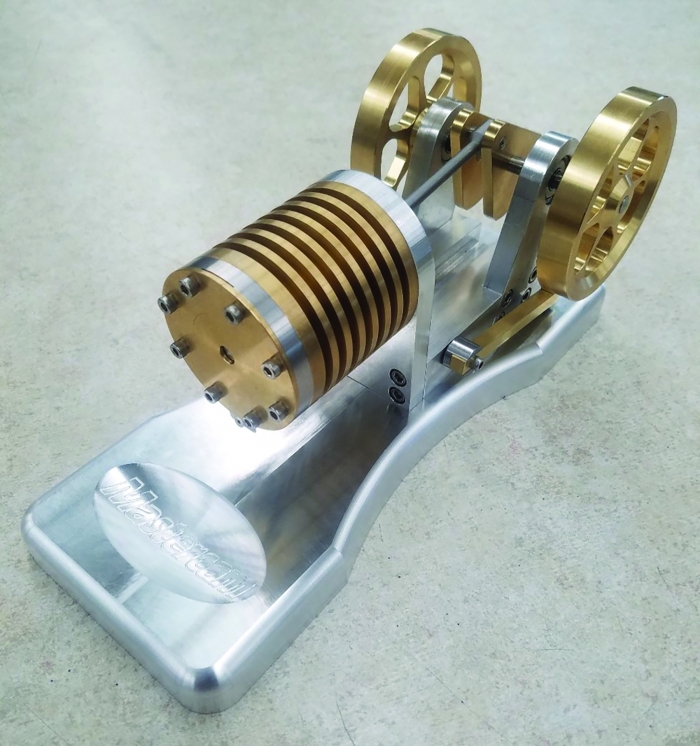

In the Postsecondary Division, Andrew Nicosia from Erie Community College submitted a vacuum engine. He wanted to challenge himself with a complex machining project for his Advanced CNC class. The engine is designed to run off a butane or propane torch held in front of the small hole in the top of the cylinder. There are 24 different parts in this assembly, and a total of 32 mill programs and five lathe programs to create the engine. Nicosia learned how to push the machine and cutting tools to their limits in Mastercam and noted that Mastercam took his abilities to a whole other level and showed him what he is truly capable of making. Sam Galliart from Pittsburg State University placed 2nd with a gorilla face injection mold.

Every participant receives a Mastercam t-shirt, and the winning students receive cash awards while their instructors are given shirts, plaques and other prizes for encouraging their students to enter. The Gene Haas Foundation provided support for the Wildest Parts Competition. The Gene Haas Foundation also awards scholarships for continuing education: $1,500 for 1st place, $750 for 2nd place and $250 for 3rd place.

Even as this year's winners are announced, it's time for teachers and students to start thinking about what they will submit for the 2019 Wildest Parts Competition. Submissions must be received before the June 28 deadline.