Redex USA showcased advanced machine tool drives at IMTS

Redex USA showcased advanced machine tool drives at IMTS

Redex USA showcased its portfolio of high-performance drives for machine tool applications at IMTS.

Redex USA showcased its portfolio of high-performance drives for machine tool applications at IMTS.

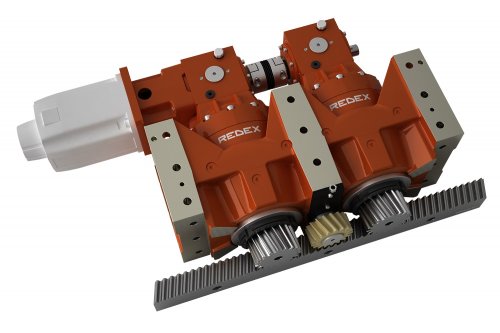

The Redex machine tool lineup features preloaded rack & pinion solutions for linear axis drives, ring gear and pinion for rotary axis drives, and 2-speed spindle drive gearboxes providing constant power to the spindle. Redex rack & pinion dedicated reducers are uniquely designed to provide high stiffness and work in combination with our DualDRIVE mechanical and TwinDRIVE electrical preloading technologies to eliminate backlash and ensure precise positioning over the entire axis length.

At Redex's booth were:

- Redex' latest SRP+ and KRP+ Rack & Pinion Dedicated Reducers. These enhanced gearing solutions feature minimal transmission error for smooth operation and low noise while providing an excellent surface finish when driving machine tool axes. Thanks to continuous enhancements, SRP+ and KRP+ rack & pinion dedicated reducers offer seven to 40 percent greater torque capacity compared to previous versions.

- - Dual KRP Rack & Pinion Drive. This closed-loop system combines two KRP reducers and a DualDRIVE mechanical preload to eliminate backlash. Only one motor is required to drive the axis.

- -MSR High-Torque VTC Table Drive. Combining two identical right angle two-speed gearboxes that equally share the driving torque during turning, this turntable drive delivers precise, C-axis motion without backlash for milling and drilling operations.