Trade fair for deburring technologies and precision surfaces is set

Trade fair for deburring technologies and precision surfaces is set

At the DeburringEXPO from Oct. 8-10, 2019, over 170 exhibitors will present innovative and advanced technologies, products and services for quality-critical production steps. This unique range of exhibitors is complemented by an attractive frame programme with theme parks, research pavilions and a bilingual expert forum.

At the DeburringEXPO from Oct. 8-10, 2019, over 170 exhibitors will present innovative and advanced technologies, products and services for quality-critical production steps. This unique range of exhibitors is complemented by an attractive frame programme with theme parks, research pavilions and a bilingual expert forum.

With over 170 exhibitors, the 3rd DeburringEXPO not only boasts an increase of around 15 percent compared to 2017's event, but is also able to present a comprehensive range of solutions for deburring, chamfering and the production of precision surfaces. "This concentration of technologies, services and providers in a focussed framework enables visitors to have a kind of overview which would not be possible at any other fair," remarks Hartmut Herdin, CEO of fairXperts GmbH & Co. KG and organiser of the DeburringEXPO.

The fact that this kind of technology monitoring is becoming more and more important emphasizes the changes in many industry sectors. Over recent years, deburring and surface finishes have become critical factors for quality and a company's competitiveness. An indicator of this is that providers of these solutions more and more often are benchmark partners for production companies that are involved comparatively early in the product development phase or an optimisation process.

Industry get-together presentation of numerous innovations

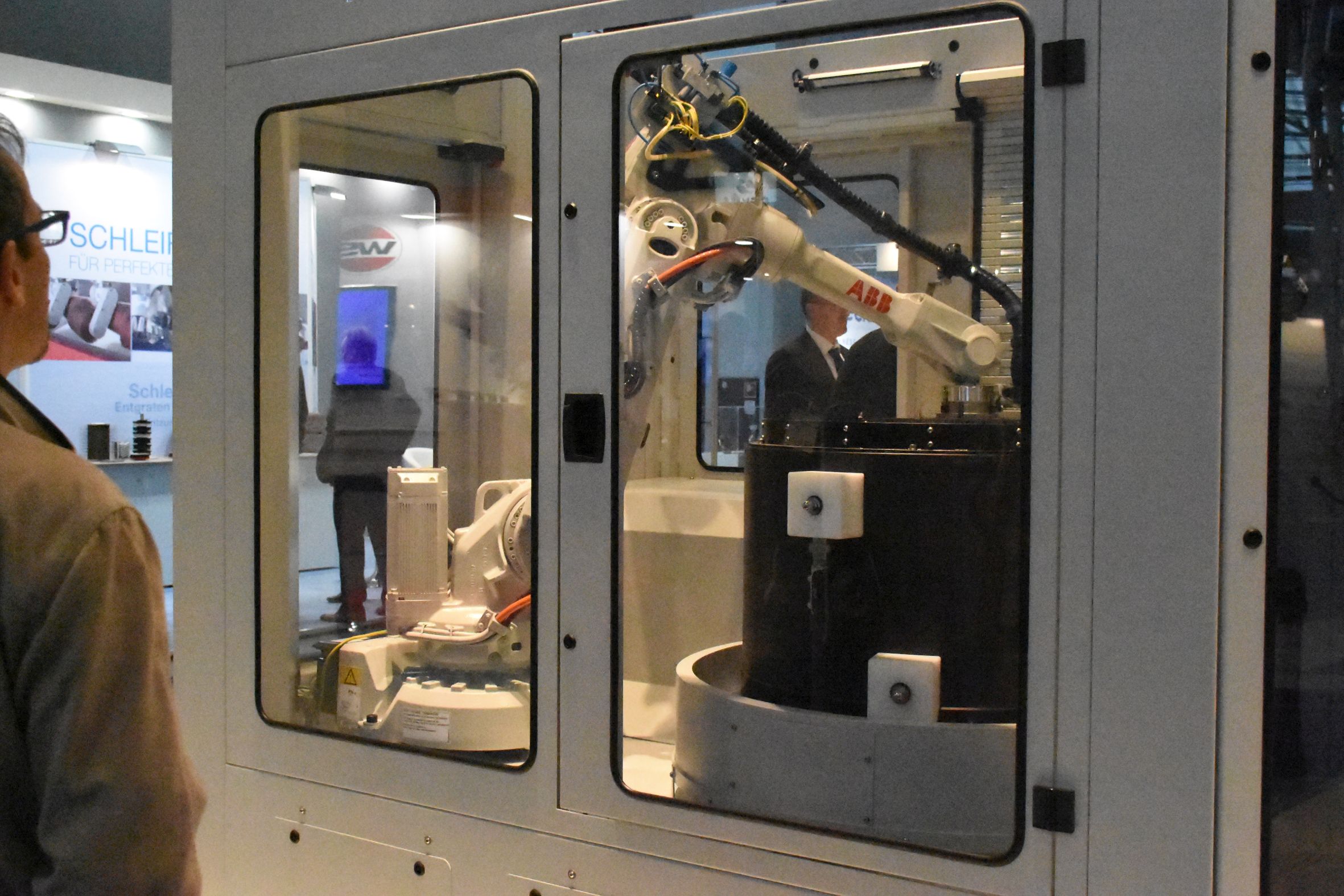

This also becomes clear when we look at the sheer number of new and advanced technologies, products and processes that will be shown in all exhibition areas at the DeburringEXPO this year. "This includes innovative machines for fully automated deburring and cleaning of components within a single process – for high-pressure water processes, as well as for ultrasonic, or dry with CO2 snow. Visitors can also expect novelties in the areas of electrochemical (ECM) and thermal deburring machines (TEM), as well as the deburring and processing of thin and thick metal sheets. Deburring tool providers will also be travelling to Karlsruhe with the most varied of novelties for automatic and manual deburring of bores and bore intersections, for example. Even when it comes to microprocessing or the manufacture of surfaces fit for application, the exhibitors' new and advanced products and technologies always ensure high precision and efficiency.

Additive manufacturing: post-processing 3D-printed parts

For the first time, the post-processing of additively manufactured parts will be demonstrated at the DeburringEXPO, both in the "AM Parks Finishing Theme Park" and by other exhibitors. "Due to the ever-increasing use of additive manufacturing in mass production, the demands placed on 3D-printed component surfaces are increasing rapidly. This development is taken into account by the new exhibition format and has garnered great interest from the respective companies," explains Herdin. The spectrum ranges from the removal of support structures through to powder removal and cleaning right up to finishing, i.e preparing the surface for the next production step. The exhibition will also present novelties in this area.

Component cleanliness: cleaning after deburring

Increasingly higher demands on the technical cleanliness of components – whether it be for smooth function or to ensure the quality of subsequent processes – cannot be met without reliable removal of burrs and flakes, as well as subsequent cleaning. The exhibitors of the theme park cleaning after deburring and further companies from all areas of industrial cleaning technology will present solutions to achieve the required cleanliness in a reliable and economical way.

Live: work steps in the process chain of metal sheet deburring

The highlights of this year's DeburringEXPO include the theme park process chain metal sheet deburring. In this event space, which was jointly initiated by experts and market leaders in the industry, various technologies and downstream processes are shown in addition to the production steps such as degreasing, removal of oxide layers, deburring, chamfering and surface finishing, originally attributed to metal sheet deburring. "All steps of this process chain will be demonstrated live on a sample part. This makes the theme park a unique performance show we have never seen before", adds Herdin.

Bilingual: expert knowledge for optimised deburring and finishing

Transfer of knowledge and exchange of experiences are the central focus of the three-day expert forum during the DeburringEXPO. A total of 29 presentations by renowned experts from industry and science will be simultaneously translated (German <> English). "With this, we are taking the considerably increasing international demand for information in the areas of deburring technologies and precision surfaces production into account," says Herdin. The program, which was worked out in technical cooperation with Fraunhofer IPK, Institute PTW, TU Darmstadt and LIMA Ventures GmbH, is divided into the following six presentation sessions: mechanical deburring, AM parts finishing, deburring and functional surface processing in one step, cleaning after deburring – deburring and cleaning, undefined deburring (blasting, TEM and other processes), as well as metal sheet deburring. Participation is free for trade fair visitors.

Latest research: Discover what is being researched

Yet another novelty of this year's leading trade fair for deburring technologies and precision surfaces is the research pavilion. This will enable visitors to inform themselves about recently completed, ongoing and future research projects influencing the quality factor that is deburring.

Further information, the list of products and exhibitors, as well as the expert forum programme can be found on www.deburring-expo.de.