Industry News

01/30/2024

As of Jan. 1, 2024, all support for Elliott Tools will transition to Elliott. This includes sales and service support for all metal finishing, burnishing, recessing and mechanical joining tools previously sold by Monaghan. This will open the door for the company to focus on its goal of being a “cutting tool expert.”

01/29/2024

Koyo Machinery USA, a provider of precision grinding machines, will be integrated into JTEKT Machinery’s range of products.

01/26/2024

Velo3D Inc., a metal additive manufacturing company, announced that Benny Buller has stepped down as company CEO at the company's request, effective immediately. Brad Kreger was appointed Interim CEO.

01/25/2024

GROB Systems, Inc., a developer of manufacturing systems and machine tools, broke ground in December 2023 on a 135,000-square-foot expansion project.

01/24/2024

Lyndex-Nikken, manufacturer and provider of high-performance machine tool accessories, has expanded its sales team to "better serve the evolving needs of industry in the U.S."

01/23/2024

The European project Target-X has launched its second open call to strengthen important economic sectors in Europe by integrating 5G and 6G, accelerating the digital transformation.

01/22/2024

Ceratizit has received an environmental award known as the Prix de l'Environnement 2023 from the Luxembourg industry association FEDIL for the process used to manufacture the carbide grades in the upGRADE family of cutting tools.

01/19/2024

CGTech, the Irvine, California-based developer of VERICUT CNC machine simulation software, celebrated 35 years of growth and innovation in CNC simulation and optimization in 2023.

01/18/2024

EXAIR Application Engineer John Ball has recently achieved CAGI CCASS (Certified Compressed Air System Specialist) certification.

01/17/2024

After a four-month voting period with around 20,000 votes cast, winners in 24 categories of the Best of Industry Awards have now been determined. WFL Millturn Technologies was one of the winners, earning the award in the Modular Machine Concept category.

01/16/2024

The United Grinding Group strengthens its Southeast Asian footprint and establishes a subsidiary in Singapore.

01/15/2024

Star Cutter Company, a provider of custom-engineered tooling solutions for precision applications, will display its cutting tools tailored for firearms manufacturing at the Shot Show 2024, Jan. 23 – 26 at the Venetian Expo + Caesar’s Forum in Las Vegas.

01/12/2024

The Certification Gives Government Agencies, Contractors, and Other Security-conscious Customers Enhanced Protection Against Cyberattacks

01/11/2024

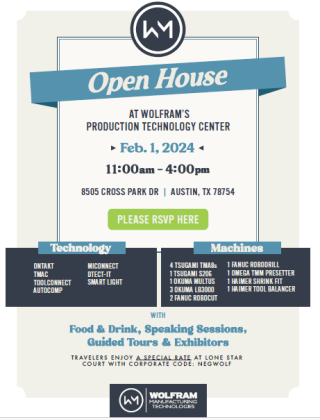

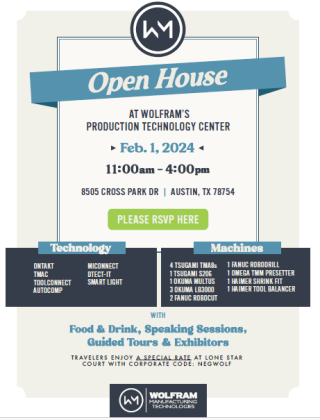

Wolfram Manufacturing Technologies, a developer and integrator of advanced machine tool technologies, has expanded its machine shop footprint, adding new machines and tripling machining throughput. These advances will be showcased at an open house scheduled for February 1, 2024.

01/10/2024

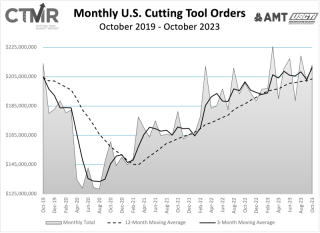

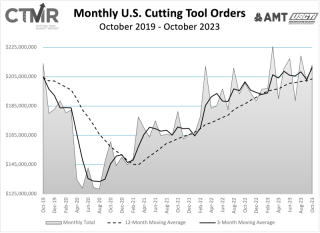

October 2023 U.S. cutting tool consumption totaled $219.2 million, according to the U.S. Cutting Tool Institute (USCTI) and AMT – The Association For Manufacturing Technology.

01/10/2024

Ceratizit has reallocated responsibilities on the executive board as of Dec. 1, 2023. Following the planned retirement of Executive Board Member Thierry Wolter from the operational business, the Executive Board will consist of three members in future: Melissa Albeck, Andreas Lackner and Frank Thomé.

01/09/2024

Surface finishing experts, Fintek, have in invested in a new Bruker Alicona EdgeMaster. The automatic metrology system for cutting tools is supplied and supported by Optimax Imaging Inspection & Measurement Ltd in the UK.

01/08/2024

The Christmas season and its traditions may have faded into memory, but one traditional Christmas icon now has a metal counterpart that will last for many Christmases to come.

01/04/2024

In his new role, Herendeen is responsible for overseeing an expansive sales team and dealer network for MC Machinery lasers, press brakes and automation equipment in North America. He also works closely with Mitsubishi factories on research and development, pricing, ordering and more.

12/13/2023

BASF’s North American Apprenticeship Development Program has expanded for a second consecutive year in 2023, launching at eight additional regional manufacturing sites.