Industry News

10/14/2019

Although the title of a book I received a digital review copy of is “Basic Benchwork for Home Machinists,” it contains information that even metalworking professionals might implement on the shop floor or at least enjoy reading.

10/14/2019

Since 1992, RobotWorx has been refurbishing industrial robots, restoring the workhorses of manufacturing environments to like-new condition. Robots are commodities today, performing everything from welding tasks to handling intrinsic materials in solar panel clean room environments. For RobotWorx, opportunity beckons when companies upgrade their plants, close their facilities, or when old robots are replaced. Regardless of their condition, RobotWorx gives used robots new life.

10/11/2019

CNC machining is a common industrial process with specific design features that work best. Learn the ins and outs of CNC design in this detailed guide.

10/11/2019

Machining a part requires knowing the correct speeds and feeds for a cutting tool and material — a skill that can take years to master. What if a resource existed that made it possible for anyone to run a CNC machine and successfully cut a range of materials, from plastic and stainless steel to titanium? What if the same resource could help seasoned machinists learn how to optimize a new cutting tool or a new material?

10/11/2019

As manufacturers continue to be challenged by a shortage of skilled workers and the need to boost productivity, automation remains a topic of significant interest. That was certainly the case at the Wisconsin Manufacturing & Technology Show. The biennial trade show took place Oct. 8-10 at the Exposition Center at Wisconsin State Fair Park, West Allis, Wisconsin.

10/10/2019

After a bit of a hiatus, I received a new book about metalworking, “Essential Guide to Metals and Manufacturing” by Krishan Katyal. The author is a mechanical engineer who has worked for four decades designing and manufacturing machine tools, consumer appliances, diesel-electric locomotives and heavy concrete construction products for Chicago area companies.

10/08/2019

NVision Inc., in cooperation with the Nasher Sculpture Center in Dallas, is making it possible for those with vision-impairment to interactively engage with some of the great works by modern sculptors. NVision, a leader in 3D noncontact optical scanning/measurement for more than 29 years, recently scanned several sculptures by Auguste Rodin (perhaps best-known for his sculpture, The Thinker) and Julio González for the Nasher. The scanning data was used to 3D-print to-scale replicas of the sculptures for a tactile educational experience for the blind and visually impaired.

10/08/2019

Master Fluid Solutions, a Perrysburg, Ohio-based manufacturer of metalworking fluids and associated chemicals, announces its acquisition of Wilhelm Dietz GmbH. Based in Düsseldorf, Germany, Wilhelm Dietz GmbH primarily serves the needs of the pipe and tube expansion, forming, wire drawing and metalworking industries under its WEDOLiT brand name.

10/07/2019

The Oregon Manufacturing Innovation Center Research and Development (OMIC R&D) announced this week that Urmaze Naterwalla has joined the organization as its Research Operations Officer. Naterwalla, formerly senior engineer for machining solutions at Boeing Portland, will be developing research operations at OMIC R&D in this new role for the organization.

10/07/2019

The National Institute for Metalworking Skills (NIMS) and the Oregon Manufacturing Innovation Center – Research & Development (OMIC R&D) have united to define a set of Metrology standards and to develop a metrology certification process. Metrology, the study of measurement, has far-reaching applications in the manufacturing industry. The ability to compare and verify a physical part against its CAD model is in high demand, and that demand is predicted to increase.

10/04/2019

At first blush, hardness and toughness may seem like interchangeable concepts, but they actually exist at opposite ends of a continuum that defines indexable and solid tool performance, particularly when it comes to carbide inserts. Harder inserts offer greater wear resistance for superior performance and tool life in hot cutting environments, while tough inserts can handle greater impacts and stressors for the highest feed and depth of cut. For any given application, there is an optimal balance of hardness and toughness – and toolmakers have worked diligently to establish metallurgic principles to offer a range of tools that can meet the diverse needs of manufacturers.

10/03/2019

Force Control Industries celebrates 50 years of manufacturing long lasting oil shear clutches, brakes and clutch brakes. Although industries and applications have come and gone in the five decades that the company has been in business, Force Control Industries continues to develop new uses for its unique oil shear technology.

10/02/2019

MC Machinery Systems is known as a supplier of Mitsubishi EDMs and laser machines, and Mitsubishi EDM/Laser is prominently displayed on the company’s headquarters in Elk Grove Village, Illinois, but several seminars focused on hard milling and 5-axis machining were presented during its EDM National open house. The event took place Sept. 26.

10/02/2019

As additive manufacturing and 3D printing of metal parts continues to make inroads into production environments, the need to efficiently and effectively finish-machine them when typically required gains importance.

10/01/2019

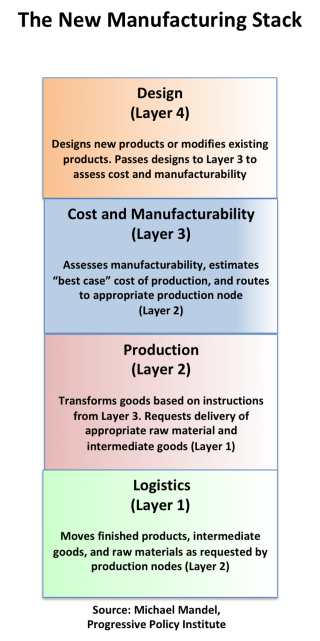

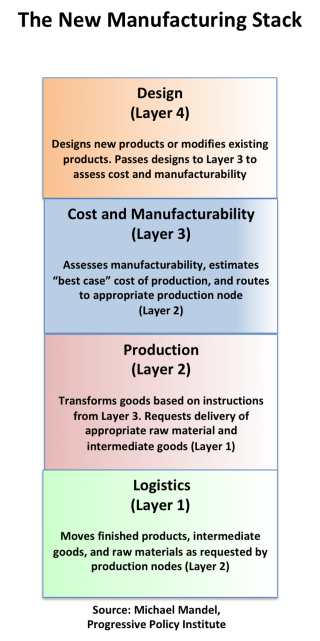

Manufacturing is transitioning from a linear supply chain world to a much more adaptable internet of goods. Just as the internet is built on the TCP/IP stack, the internet of goods will be built on a new manufacturing stack that goes beyond the factory floor.

10/01/2019

Our discourse on the manufacturing renaissance is marked by a failure to take hysteresis into account. First, I will select representative voices from the discourse. Then I will present a bracing article from IndustryWeek. I’ll conclude by merely alluding to remedies.

10/01/2019

ARCH Cutting Tools announced that the Richards Micro-Tools product portfolio is being rebranded as KEO Micro Tools.

09/30/2019

The National Institute for Metalworking Skills (NIMS) is now offering standardized CAM credentials, CAM Milling and Turning. “The CAM field continues to grow and is expected to create almost 100,000 new programmer, designer, and engineer jobs by 2024,” said NIMS Executive Director Montez King. “It is imperative that people entering the field are properly trained and capable, and these credentials show a potential employer that applicants are ready to program CNC machine tools. Further, employees already on the job may wish to secure an official, portable, industry-recognized certification.”

09/27/2019

Precision and efficiency have become the leading demands for manufacturing. Modern equipment is changing rapidly. Sturdier, harder materials are used, complex geometries with tight tolerances and fine surface finishes are required, and all that has to be done at a faster pace. This race toward product perfection involves using professional custom machining services for more and more industries and for a lot of different purposes.

09/27/2019

When tariff hikes began in spring 2018, companies associated with manufacturing immediately went on alert. Over the past year and a half, continued escalations have increased pressure on U.S. and China relations, leaving international companies that rely on Chinese manufacturing looking to reduce uncertainty with short- and long-term solutions.