Industry News

03/07/2018

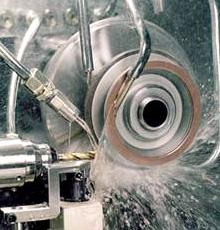

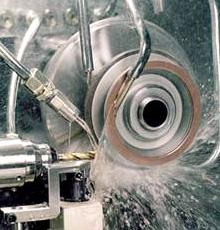

For the May issue’s focus on abrasive machining, I’m writing a multiple-source article about honing. One of the sources is Lapmaster Wolters LLC.

03/06/2018

Julian Cornwall, a 17-year-old junior in the Butler Tech precision machine program at Colerain Career Center, has a big decision ahead of him. Companies looked at his portfolio and shop samples and talked to his instructor about his work during a recent skills competition. He had 11 job offers in hand when a trio of executives from the Feintool Group stopped by his machine to talk to him. When they left, his options had increased by another offer.

03/06/2018

A precision machining supplier has come up with a way to address the skills shortage problem. Micron Manufacturing Co., Walker, Mich., lets workers create their own schedules. You want to be there for your first-grader's field trip? Do it. Want to have a long lunch with your aging mom? You can.

03/06/2018

Nearly 100 percent of the solid-carbide tool assortment is suitable for reconditioning, according to Sandvik Coromant Co. Once a solid-carbide tool has been reconditioned three times and is no longer a candidate for reconditioning, it can be recycled.

03/04/2018

Futura Automation LLC, Scottsdale, Ariz., added George Wilken to its management team.

03/04/2018

The surface treatment global business unit of Ludwigshafen, Germany-based BASF SE's coatings division, operating under the Chemetall brand, was awarded the highest supplier award in the aerospace company Airbus SE, Leiden, Netherlands, Supply Chain & Quality Improvement Program known as SQIP.

03/04/2018

Seco Tools AB, Fagersta, Sweden, and MachiningCloud Inc., Camarillo, Calif., are partnering to provide Seco Tools product data in the cloud.

03/04/2018

Metrology provider ASF Metrology SRL, Varallo, Italy, is acquiring the coordinate measuring machines business from metrology provider Nikon Metrology NV, Leuven, Belgium.

03/03/2018

2018 marks the 35th anniversary of CNC Software Inc., Tolland, Conn., the developer of Mastercam CAD/CAM software.

03/03/2018

Röhm Group, Suwanee, Ga., is now part of Dr. Helmut Rothenberger Holding GmbH.

03/03/2018

CGTech, Irvine, Calif., the developer of Vericut software, is celebrating three decades of innovation and consistent growth.

03/03/2018

Dave Greene joined Franklin Bronze Precision Components LLC, Franklin, Pa., as operations manager.

03/03/2018

Kitagawa North-Tech Inc., Schaumburg, Ill., which manufactures standard chucks, advanced chucks, custom-engineered workholding and steady rests, hired Edward Borsos as regional sales manager.

03/03/2018

Precision Surfacing Solutions, Mount Prospect, Ill., formerly Lapmaster Wolters Group, a supplier of equipment and services for precision lapping, polishing, grinding and honing, acquired Reform Grinding Technology GmbH, a provider of machine tools and systems for high-precision grinding applications.

03/02/2018

Arno Werkzeuge USA LLC, Harvard, Ill., a manufacturer of cutting tools and positive- and negative-style inserts for metalcutting machine tools and Swiss-style turning machines, hired Rob Hampton as technical support and sales engineer for the Northeast region of the U.S.

03/02/2018

Sunnen Products Co., St. Louis, acquired BTA Heller Inc., a U.S.-based manufacturer of deep-hole tooling and systems for primary hole generation.

03/02/2018

GWS Tool Group LLC, Tavares, Fla., the parent company of GW Schultz Tool and CGI Tool, acquired Alliance CNC Cutter Grinding Services Inc.

03/02/2018

Ben McGruder was appointed director of customer service and inside sales for Dorner Manufacturing Corp., Hartland, Wis.

03/02/2018

Hypertherm Inc., Hanover, N.H., a manufacturer of industrial cutting systems and software, is celebrating its 50th year of industrial cutting innovation by introducing programs designed to deliver greater value to longtime customers.

03/02/2018

Mazak Corp., Florence, Ky., named Jim Rutan general manager for the Northeast region.