Industry News

12/27/2022

Mazak continues to grow and invest in Kentucky machine tool production operations.

12/23/2022

Do you have safety resolutions for the new year? If so, we have some advice for you.

12/22/2022

How can you get the most out of an existing press-hardening line? According to AP&T, a company that develops high-performing production solutions for the sheet metal forming industry, when updating a press-hardening line there is significant potential to shorten cycle times and increase production.

12/21/2022

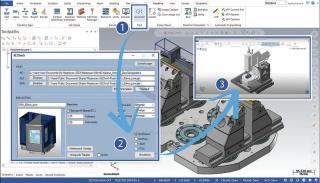

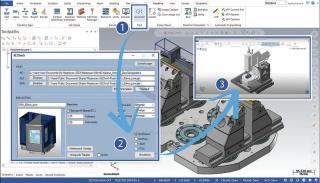

Under a new partnership that provides G code simulation with Mastercam, users can simulate the entire machining process with the click of a button.

12/20/2022

OSG USA Inc., a subsidiary of OSG Corp., has promoted Donna Gialo to vice president of marketing, e-commerce and customer success.

12/19/2022

OSG USA Inc., a subsidiary of OSG Corp., announced that Rick Harris has been hired as national accounts strategic manager.

12/16/2022

Magid wants to help the industrial workforce battle stress, which costs U.S. industries $300 billion a year.

12/16/2022

Shortly after Mike Winters started his company in his garage on Nov. 10, 1982, first as Winters Carbide Tools and now TJ Grinding, in Waukesha, Wisconsin, he had the good fortune of being at a K.O. Lee facility in South Dakota and saw an interesting piece of equipment -- the FastGrind TG4 from an Australian company called ANCA.

12/15/2022

Jorgensen Conveyor and Filtration Solutions has entered into a partnership with Will-Fill, a manufacturer of fully automatic coolant monitoring and managing systems.

12/14/2022

Sandvik Coromant and NAIT celebrate the renewal of a long-standing 15-year partnership through 2025.

12/13/2022

Platinum Tooling now offers Rineck shrink-fit tooling and shrink-fit machine technology for customers in the United States and Mexico.

12/12/2022

Mikron Tool has constructed a 1,000-square-meter, two-story production facility.

12/09/2022

Jorgensen Conveyor and Filtration Solutions has promoted Karl Kleppek to the position of company president and COO.

12/07/2022

Walter USA has relocated its Americas Technology Center along with the regional business operations from Waukesha, Wis., to Greer, S.C.

12/07/2022

Rollomatic Inc., a subsidiary of Rollomatic Holding Switzerland, has appointed Jason Hodgin as regional sales manager for several key manufacturing areas in the Southeastern and Central United States.

12/06/2022

David Ducsai has been named group customer service manager of North America for The Rollomatic Group.

12/02/2022

In the latest episode of ANCA Academy’s video series, host Hugh Ingham, an ANCA mechanical and application engineer, has an in-depth discussion of machine fundamentals.

11/30/2022

There are a lot more than dollar signs to consider before purchasing a new machine tool.

11/29/2022

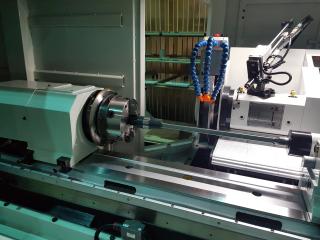

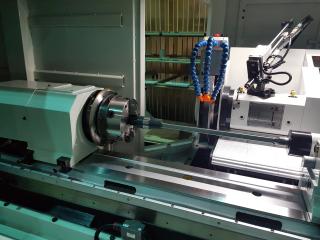

Palmary Machinery cites NUMgrind software as a key product differentiator.

11/28/2022

Challenging customer projects have a long tradition at Mikron Tool. In recent years, the number of inquiries from the machining industry from a variety of areas has increased sharply, always looking for the most suitable drills and milling cutters or more efficient machining strategies.