Industry News

11/25/2022

Regional Sales Manager Nick Falgiatano has been promoted to marketing manager of sales area Americas effective Dec. 1.

11/23/2022

The company relies on veterans for their transferrable skills and rock-solid work ethic.

11/22/2022

Mohawk Innovative Technology teams with Velo3D to boost efficiency and durability, taking 60% off the price of anode off-gas recycle blowers.

11/21/2022

The World Robotics Report shows that robot installations in the United States were up by 14% to 34,987 units in 2021 -- the second most successful year for the robotics industry in the U.S.

11/18/2022

Bystronic Laser AG, working jointly with EMCO GmbH from Hallein/Salzburg, undertook a complete redesign of the machine frame machining process so that it could be carried out by EMCO Mecof's Megamill high-gantry milling machine.

11/17/2022

Abrasive Technology LLC has named Guy Topping as its managing director of Abrasive Technology Ltd.

11/16/2022

Representatives from ANCA and Fravic Daunert signed a distribution contract at IMTS 2022 to sell ANCA products in portions of Mexico.

11/15/2022

Lotus Cars Ltd. is known for the design and manufacture of high-performance cars born out of legendary success on the racetrack. Its latest sports car, the Emira, is by far the most accurate model ever built by Lotus thanks to the use of a 5-axis HC-90TR twin-arm coordinate measuring machine from LK Metrology.

11/14/2022

Parts cleaning is critical to achieving precision, process reliability and high efficiency in processes and production technologies.

11/11/2022

The production of high-precision parts with complex interior geometries requires top quality along the entire production chain. In order to be optimally prepared for future cleanliness requirements, a Swedish manufacturer replaced one of its existing solvent cleaning systems. They chose an Ecoclean EcoCcompact fitted with Ultrasonics PLUS, to mention only one of the system's features.

11/10/2022

Additive manufacturing is not perfect, and one area where significant issues reside is in the surface finish of AM parts as they come out of the build chamber or off the build plate.

11/09/2022

Power skiving is the fastest-growing method of gear machining.

11/08/2022

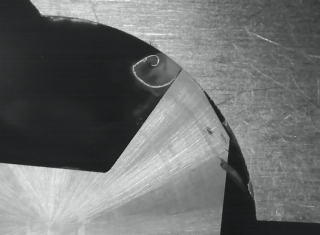

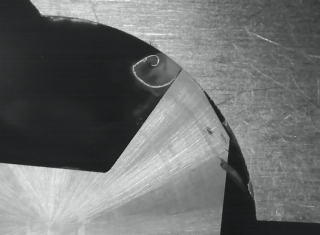

The research and development team at Blaser Swisslube, a Swiss expert in metalworking fluids, set about planning and implementing an idea to capture a machining process, chip formation and the behavior of the metalworking fluid more precisely than ever before through photos and videos. The idea came about as part of a joint project with the renowned ETH Zurich.

11/07/2022

Vomat developed a new air conditioning unit that converts excess energy from production and peripheral machines, such as grinding machines, oil extraction systems and machine pumps, and can then use it to heat or cool the production hall.

11/04/2022

ANCA USA, a manufacturer of CNC grinding machines, has named Amanda Bakun to the newly created position of marketing and communications manager for the Americas.

11/03/2022

Big Daishowa will donate a tooling certificate valued at 20 percent of every order from an NTMA member company to the buyer’s school of choice.

11/02/2022

The two-day event scheduled for November 2-3 in Auburn Hills, MI, focuses on advanced manufacturing solutions.

10/31/2022

Automation tasks are becoming more challenging. However, using intelligent software in combination with the relevant automation solutions not only enables workpieces to be loaded and unloaded but also means that machine tools can be set up fully automatically through the automatic replacement of tools and clamping devices.

10/28/2022

The Haoneng Group, a Chinese manufacturer in the field of vehicle transmission synchronization, is operating four WGT series inspection machines from Liebherr to help ensure the quality of its components.

10/27/2022

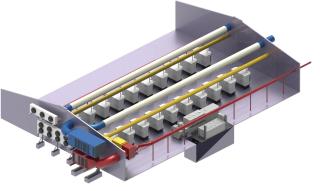

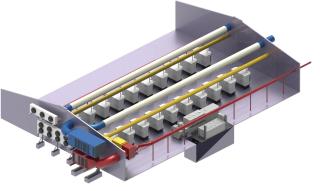

At the Teisnach plant of the Rohde & Schwarz technology group, the PHS 1500 Allround pallet handling system from Liebherr-Verzahntechnik GmbH automates four HF 5500 5-axis machining centers from Heller.