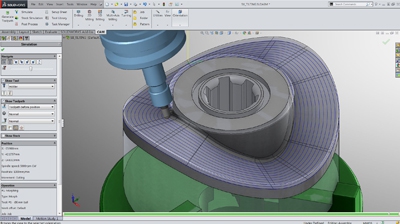

Autodesk announced the release of HSMWorks 2015, a fully integrated CAM solution for users of SolidWorks software. The availability of HSMWorks 2015 marks the third major release of the HSMWorks product line since Autodesk acquired HSMWorks in October 2012. In that time, the company has also released twelve updates with hundreds of new features and enhancements. These enhancements allow users to turn their models and assemblies into machined parts, all within a fully integrated design to manufacturing workflow.

"This new release is a great example of our ongoing commitment to our customers, regardless of which CAD system they use," said Robert "Buzz" Kross, senior vice president at Autodesk. "The feedback from users tells us HSMWorks is valued for its integration, ease-of-use and performance. This release takes the software even further with innovative new updates and features."

HSMWorks 2015, with support for SolidWorks 2015, includes many new enhancements, including a significant update to Adaptive Clearing, the product's high-efficiency roughing technology. It reduces valuable cycle time from machining jobs by taking advantage of highly efficient toolpath motion that maintains constant cutter engagement during material removal. The updated Adaptive Roughing feature also now includes taper support for helical ramps, enhanced stay-down linking and optimized z-level transitioning, which directly contributes to reduced cycle times and more efficient operation on the machine. Stock simulation has been updated with improved performance in 3D mode, important for customers in the mold/die industry and those who frequently work with large models with 3D and sculpted surfaces.

HSMXpress 2015, a free version of HSMWorks offering professional CAM capabilities exclusively for 2-½ Axis milling machining projects, has also been released as part of this update. HSMXpress includes all the same 2D Milling and Drilling capabilities as HSMWorks, along with solid part simulation and post processing system.

HSMWorks 2015 also supports the latest Intel Xeon Processors and high-end workstations, like the HP Z840 Workstation, configurable up to 36 total processor cores in one system. This allows HSMWorks 2015 to take advantage of the latest in computing power to speed toolpath calculation and post processing times; making it easier to accommodate last minute engineering changes and get CNC programs to the shop floor faster.

"Our development efforts are 100 percent focused on delivering meaningful tools that help users produce professional quality results, regardless of their level of experience," said Anthony Graves, CAM product manager at Autodesk. "HSMWorks has always been a customer-driven product and this new release is a prime example of how user input results in better software."

"As a long-time HSMWorks and SolidWorks customer, I was anxious when Autodesk acquired a tool that had become an essential part of my manufacturing operations," said Steve Pearson, president and head engineer at Wills Wing. "With the release of HSMWorks 2015 I am more confident than ever that Autodesk is committed to the HSMWorks product and the SolidWorks community."

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.