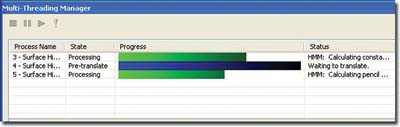

Multi-threading gives you the power to segment complex tasks in a multi-core computer, delivering faster processing as well as other benefits. Mastercam Mill from CNC Software Inc. introduces multi-threading support, and gives you the option to turn it on or off. This degree of control allows you to optimize performance for a particular job and environment. With multi-threading turned on, toolpaths that are designed to be multi-threaded will be processed in a multi-threaded mode. Toolpaths not designed for multi-threading will be processed as they would normally, without any action on your part. The multi-threading manager directs the supported toolpaths to their own core processor for processing or regeneration in separate threads as processors become available. During this processing, Mastercam is free to continue working on other tasks. You have control over the number of processors to use and the priority of specific operations being processed. You can also pause and cancel processing of any particular operation. Multi-threading delivers two benefits. First, you can continue working on other tasks in Mastercam while the multi-threading manager processes toolpaths. Without multi-threading, users have had to run multiple Mastercam sessions so that other work could continue while waiting for Mastercam to process a toolpath. A second benefit is an often dramatic decrease in toolpath processing time.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.