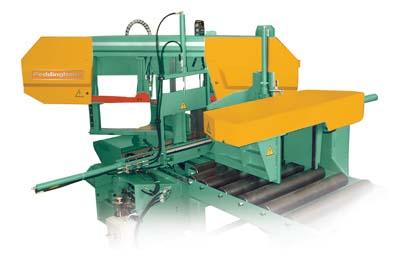

Peddinghaus Corp. offers a wide range of Eco-Line band saws for cutting of steel. The heroes of any shop are band saws such as the 410 DGA and the 320 G-HSS, as they are quick, efficient and take up minimal footprint.

Peddinghaus specifically developed the Eco-Line steel band sawing machines to meet the needs of daily production requirements. These patented Peddinghaus band saws offer an economical solution while providing the superior cutting performance, which Peddinghaus band saws are known for.

As with all Peddinghaus products, the Eco-Line band saws were developed with the user's needs in mind. These saws can cut at a 30 degree, 45 degree, 90 degree, and 135 degree angles. Offering a full range of capabilities, the Eco-Line band saws facilitate the integration of straight and miter cuts into the section size.

These heavy-duty saws with a patented miter system are packed with features to fit the needs of day-to-day use. This line that is best suited for cutting material with different cross-sections and frequent change of straight miter cuts. The swivel of the saw head remains the same for each miter cut above the intersection of the saw blade, and fixed vise so that there is a datum measuring point that does not change, resulting in no material loss. As with all Peddinghaus equipment, the saws offer plenty of power and will provide you with years of trouble-free operation.

The 320G-HSS model delivers fast and efficient miter sawing economically. The 320G-HSS saws up to 305mm (12") high, and 495mm (19.5") wide at 90 degrees, with a 178mm (7") high, and 178mm (7") wide capacity up to 60 degrees. The 320 Series band saws are designed and manufactured for lighter duty operations. However, like its counterparts, the 320 models are built with the same rugged performance components. This saw is capable and ready for cutting tasks associated with beams, columns, tubing, pipe, angle, channel, round and square stock.

The production minded 410 DGA 2300 is ideally suited for streamlined orientated manufacturing, steel stocking centers and fabrication shop production. This automated saw delivers CNC accuracy and repeatability up to 410mm (16") high and 698.5mm (27.5") wide at 90 degrees as well as 400mm (16") high and 317.5mm (12.5") wide up to 60 degrees.

Contact Details

Related Glossary Terms

- bandsaw blade ( band)

bandsaw blade ( band)

Endless band, normally with serrated teeth, that serves as the cutting tool for cutoff or contour band machines.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- sawing

sawing

Machining operation in which a powered machine, usually equipped with a blade having milled or ground teeth, is used to part material (cutoff) or give it a new shape (contour bandsawing, band machining). Four basic types of sawing operations are: hacksawing (power or manual operation in which the blade moves back and forth through the work, cutting on one of the strokes); cold or circular sawing (a rotating, circular, toothed blade parts the material much as a workshop table saw or radial-arm saw cuts wood); bandsawing (a flexible, toothed blade rides on wheels under tension and is guided through the work); and abrasive sawing (abrasive points attached to a fiber or metal backing part stock, could be considered a grinding operation).

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).