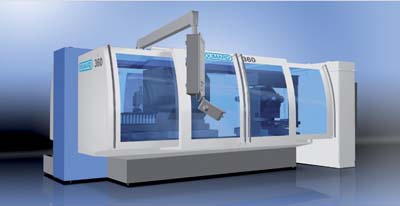

The new VM 360 ID/OC grinding machine from Peter Wolters of America Inc. was developed from the design of the proven VM 300 grinding machine. VM 360 operates with seven CNC axes, which can be optionally supplemented by another five CNC axes. For this reason the Peter Wolters continues its performance according to the requirements of their customers within the aircraft industry, the spindle industry as well as other mechanical engineering industries. In a single pass, the VM 360 grinds workpieces with a weight of up to 1300 lbs., a length of up to 52" and with an OD of up to 32" . One major feature is the stable and rigid turret-mounted grinding spindles for external grinding. It carries two grinding wheels; each with diameters of 16" or 20". The VM 360 can therefore be used as an external cylindrical grinding machine. For internal grinding, four separate high-speed grinding spindles are mounted on a second indexing turret.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- cylindrical grinding

cylindrical grinding

Grinding operation in which the workpiece is rotated around a fixed axis while the grinding wheel is fed into the outside surface in controlled relation to the axis of rotation. The workpiece is usually cylindrical, but it may be tapered or curvilinear in profile. See centerless grinding; grinding.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding machine

grinding machine

Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpiece surfaces. When ultrasmooth surfaces and finishes on the order of microns are required, lapping and honing machines (precision grinders that run abrasives with extremely fine, uniform grits) are used. In its “finishing” role, the grinder is perhaps the most widely used machine tool. Various styles are available: bench and pedestal grinders for sharpening lathe bits and drills; surface grinders for producing square, parallel, smooth and accurate parts; cylindrical and centerless grinders; center-hole grinders; form grinders; facemill and endmill grinders; gear-cutting grinders; jig grinders; abrasive belt (backstand, swing-frame, belt-roll) grinders; tool and cutter grinders for sharpening and resharpening cutting tools; carbide grinders; hand-held die grinders; and abrasive cutoff saws.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.