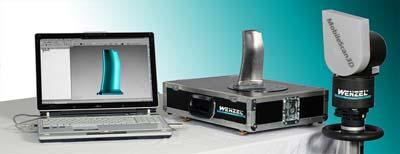

Giles Gaskell, North American sales manager for 3D Imaging Products for Wenzel/Xspect Solutions says, "For anyone who is looking for portable 3D imaging technology for reverse engineering or inspection, the MobileScan3D system provides the quality and repeatability of a CMM-based laser scanner in a portable and highly flexible system. MobileScan3D's configuration is not constrained by a CMM frame or portable CMM arm and has interchangeable laser sensors to adapt to different sizes and shapes of parts, from jewelry to full-sized automobiles. Because MobileScan3D offers full CNC automatic scanning, the accuracy of the acquired dataset is significantly enhanced over the same data acquired by other portable systems and provides automatically structured and ordered data, minimizing subsequent data "clean-up" and processing time. In addition, MobileScan3D can also be used for the verification of production parts against nominal geometry data and can either be used in complete CNC mode or in semi CNC mode where the motors can be disengaged and the laser manually guided to define the scan path before re-engagement for CNC scanning. This semi CNC mode allows for rapid set-up for inspection of one-off parts." Gaskell adds, "There are many portable scanning solutions available today, but almost all have human influences on the actual measurement results that can cause inconsistency in measurements. Our research with customers has indicated that most companies would like to have a portable measurement system that takes the human influences out of the equation. Hence, the development of MobileScan3D." MobileScan3D comprises of a 2-axis CNC swivel head providing A and B rotational axes; the scanning sensor is mounted to the swivel head using a "quick-change" adaptor, minimizing changeover times between the three available sensors. The MobileScan3D laser scanner system consists of a tripod with three interchangeable scanning heads; a 100mm to 290mm head with accuracy of plus or minus 0.01mm; a 400mm to 570mm head with accuracy of plus or minus 0.05mm; a 1000mm to 1800mm head with accuracy of plus or minus 0.15mm and an average line length of 43, 185 and 270mm, respectively. This system has full 3-axis CNC capability and uses a red laser stripe to scan up to 100,000 points per second. Scanning accuracy down to 10µm can be achieved with the system. The density of scanned lines can be controlled by programming the velocity of the A and B axes of the swivel head. Integral thermal sensors, with environmental control, insure scanned data set accuracy. The sensor body is manufactured from carbon fiber, eliminating and thermal growth due to heat generated from the laser source. The sensor outer-casing is independently mounted, allowing isolation from the sensor optics and electronics, eliminating the potential for calibration errors caused by rough system handling during transit. Interchangeability takes only a few minutes. The system is controlled by a PC and a small portable controller. It has the ability to non-contact scan with full CNC control using a simple operator user interface. The scanned ordered dataset is streamed real-time into the accompanying data evaluation software. A full 3D CAD model can be generated for output in STL, IGES, STEP or ASCII file formats. MobileScan3D can be supplied with the Wenzel Pointmaster V5 software or any of the major reverse engineering and verification software packages.

Contact Details

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.