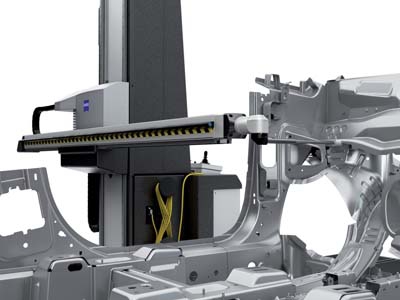

Carmet II from Carl Zeiss was developed specifically for suppliers and manufacturers in the automotive industry. This new horizontal-arm measuring machine is available in four sizes up to a measuring range of X = 7m, Y = 1.6m and Z = 2.5m. It comes standard with the RDS stepping articulating probe holder featuring CAA (Computer-Aided Accuracy). The F.I. (Foam Insulation) technology successfully introduced with the new ACCURA is also used for Carmet II. Carmet II has a relatively small footprint. This is the result of the onboard controller on the machine. Sensitive machine components are enclosed in a special high-tech material, thus providing the machine with high temperature stability. Machine availability is increased through the shortened maintenance time. All maintenance-relevant parts are easily accessible. With the new CNC-guided Carmet II, Carl Zeiss offers a measuring machine with a robust guideway system whose premounted friction drives unite a high level of safety and quietness. The horizontal-arm design makes it easy to load the measuring machine even with the complex components that are commonly found in car body measuring.The design also facilitates access to the measuring location. The company says the machine is not only robust, but also flexible: numerous angular positions of the stylus system provide maximum flexibility. Thanks to RDS and CAA, users of touch-trigger sensors achieve shorter calibration times and thus increase their productivity. Hard-to-reach areas, such as in the wheel arch of a car body, can be easily accessed with different touch-trigger sensors and extensions up to 350mm.

Contact Details

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.