Is there a user out there that has never experienced the following situation? Programmed nominal data does not comply with real, actual data. A situation that can lead to costly collisions within the machine tool. With its new software module tool realityCheck ZOLLER has developed a solution to prevent expensive machine crashes.

So far, users have only been able to ensure collision-free machining while working in single record mode. And over the past years, simulation systems have been developed trying to avoid such practice. Most of these systems however leave the following problem unsolved: the baseline information used for the simulation typically does not match up with reality.

Especially in the tool and mould making industry a considerable amount of time passes between the creation of a NC program and the actual use of "real" tools in the machining center. A lot of times, another simulation with the "real" tool data becomes necessary shortly before the tool is actually being used.

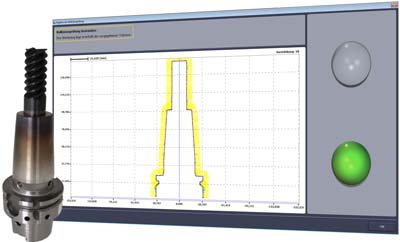

ZOLLER's newly developed software module tool realityCheck allows a fast and precise collision check, to determine whether the scanned tool matches the tool originally used for the simulation. The tool's real, actual contour is recorded while being rotated, thus simulating the actual machining process.

This check makes collisions virtually impossible. The user simply has to enter the start and end point of the requested tool contour. The measuring program will then automatically position the camera at the starting point and measure the contour during rotation. Afterwards, an actual/nominal comparison along with the results of the collision check are being displayed on the screen. A "green light" means "Go," the machining process can be performed, and "red" stands for "Attention: collision!"

This software module is available for all CNC-controlled tool presetter and measuring machines from ZOLLER.

Contact Details

Related Glossary Terms

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.