With its global 3i modernization program, REDEX has transformed its Senonches plant into a state-of-the-art center of gear excellence. As a result, REDEX is now offering aeronautical and motor racing quality gears as a standard in its axis drives to machine tool OEMs.

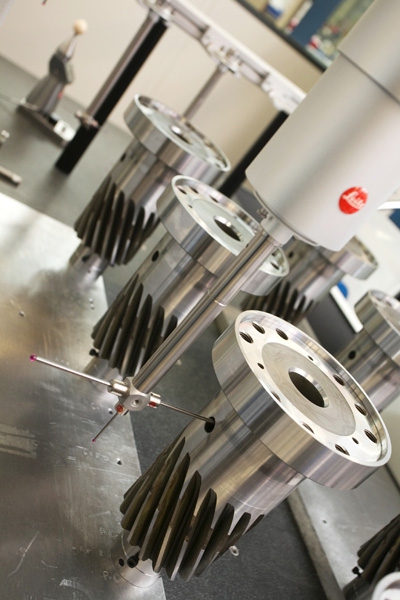

REDEX has invested more than 20 million euros upgrading the company´s industrial organization to the most modern levels. The company's second French plant (Senonches) has been transformed into an innovative gear facility in the fields of cutting, finishing, and 3D control (cylindrical gear, straight or helical and spiro-conics).

The production methods used there are the most unique for industrial gearbox producers (for instance: HP-GS hard cutting of spiro-conics or superfinishing of inner teeth). The ultramodern machines utilized worldwide, despite their full digital control of multiple CNC axes, do not operate at optimal levels without the tools and production methods developed specifically by REDEX.

With 65 years of experience in top quality planetary gearbox design, REDEX engineers are able to provide the company's specific added value through these tool designs. This vital additional input for the running of the machines accounts for up to 40 percent of the global investment costs. The workshops receiving such advanced machine-tools are fully air-conditioned to work almost as "clean rooms." The industrial processing of gears, where the required accuracy is almost everywhere in theµm magnitude, cannot escape from such a high-tech global environment.

These gears are mounted in the core of planetary reducers and advanced gearboxes fitted with the most modern machine-tools (built by renowned OEMs such as DMG, Mazak, Mitsubishi), with REDEX as a key supplier.

The quality in the finishing of the gears is not just a theoretical target for engineers, but rather an integral component in the constant improvement of industrial drives. REDEX offers machine builders better efficiency, lower noise level, longer lifetime and makes innovation and new design more risk-free than ever.

The Gear Center has been developed in less than 5 years by drawing upon the internal resources of the REDEX group as well as the centers of excellence in mechanical training of the INSA of Lyon and Rouen. Automation, flow management, and operating methods complete the range of techniques used in the factory, measuring more than 5000m2, employing 50 high skilled engineers and technicians, and carrying out a trade volume of nearly 10 million euros. Since 2012, the Gear Center of Senonches, in addition to the internal REDEX group, has developed subcontracted trade at high added value for the aeronautical sector.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.