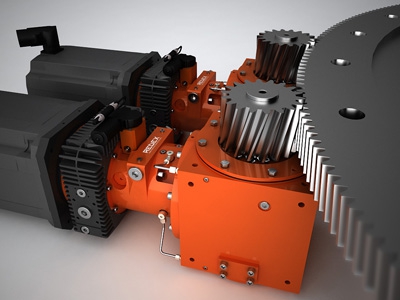

The latest version of REDEX' MSR TwinDrive dramatically simplifies the mechanical transmission system on large vertical lathes. As a result, the design of turning tables becomes much easier while improving the precision and making the machine more compact. REDEX has once again produced innovative products and solutions that offer machine builders cutting-edge designs that feature easy use and maintenance.

REDEX has once again enhanced its solutions for turning tables on large vertical lathes. The latest MSR drive designs have been refined using the newest generation of drive and control systems (i.e. from Siemens CNC or FANUC). The MSR drive is composed of two identical gearboxes (TwinDrive system), sharing the driving torque (50 percent-50 percent) during turning operations. With the help of the CNC system which manages the motor preload torque, the system is able to cancel 100 percent of backlash. In addition, MSR exclusive features enable a very accurate positioning level. Thus, it allows the execution of additional functions on the C-axis, without any additional mechanical devices. For instance, top accuracy is kept during milling operations with one motor driving and the other motor braking.

REDEX provides the unique commercial solution for turning and milling drives in the machine-tool market. Before MSR, turning table manufacturers used 2 different types of drives when a C axis was needed: a main drive for turning operations driven by a big spindle motor and a feed-preloaded gearbox to cancel the backlash during C-axis mode that needed to be clutched and unclutched to the crown. In addition, the main drive need to be shifted to neutral ratio.

The MSR drive solution from REDEX reportedly dramatically simplifies the design of turning table mechanical transmission systems. It eliminates the need for developing a complex and expensive gearbox for the C-axis, including a complicated system of clutching/unclutching, according to the company. A solution with two motors is less expensive and easier to manage. In comparison to high-duty turning tables used in conventional configurations that require a 160kW motor, the MSR uses two 80kW motors, which are more standard and less expensive (despite the fact that there are two of them). When the diameter of the chuck or part to machine is large, conventional home-made kinematics consisted of using a different stage ratio of 1/1, which resulted in high costs and loss of efficiency. MSR kinematics allow the drive to be placed right under the chuck directly meshing with the crown. Spare parts management is simplified with the use of a smaller motor. Furthermore, there is no need to manage the C-axis gearbox manufacturing with all its components.

For this new MSR drive solution, developed as a turnkey system by REDEX, the latest generation of MSD two-speed gearbox is combined with the improved version of cubic R Series right angle bevel gearbox. The design upgrade includes a new and more compact and reliable speed changer as well as a new lubrication arrangement. The external appearance has also been improved as required for high-tech machine-tool component design. Supplied as a self contained sub-assembly, this integrated and compact system is ready to be implemented. Depending on machine arrangement, OEM can use the bevel box as an option.

The new range improves features of the 4 sizes, MSR330- MSR640- MSR650- MSR660 with torque capacity at pinion from 2000/4000Nm (2 x 40Kw motors) up to 9000/18000Nm (2 x 100Kw motors) with 3 possible ratio combinations of 7.66&2, 9.88&2, 11.49&3. This solution, combined with pinion/ring ratio of about 10 to 15 offers turn table torques from 20 0000Nm up to 270 000Nm and global ratios (gearbox + ring gear) of 77/20 and 172/45.

Contact Details

Related Glossary Terms

- backlash

backlash

Reaction in dynamic motion systems where potential energy that was created while the object was in motion is released when the object stops. Release of this potential energy or inertia causes the device to quickly snap backward relative to the last direction of motion. Backlash can cause a system’s final resting position to be different from what was intended and from where the control system intended to stop the device.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.