As someone who visits job shops and manufacturers almost daily, I know why some are thriving, while others struggle. The ones that are thriving have invested and continue to invest in equipment, software, training and consulting services. Those struggling often say, “I would invest more in these areas, but I can’t afford them because my competitors keep underbidding me. They must be giving parts away.”

More often than not, owners of thriving shops are not underbidding their competitors—they’re out-machining them. They are taking full advantage of all the competitive benefits made available by their machining systems and advice from consultants to operate more profitably. In short, they’ve learned to pick the low-hanging fruit available to them and reinvest their profits to bring even higher fruit within easier reach. The following are some examples.

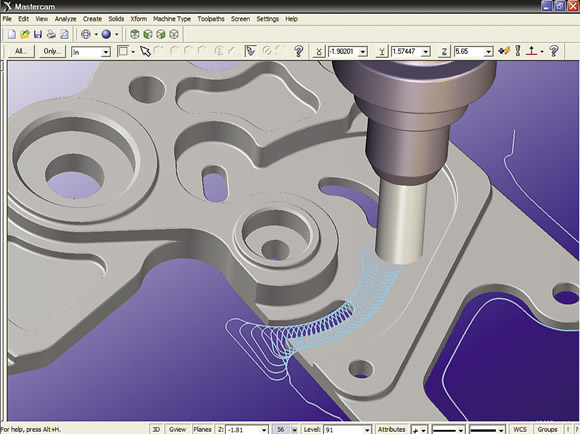

Courtesy of CNC Software

Trochoidal toolpaths make circular nibbling cuts around corners to cut faster and extend tool life. Almost all CAM software offers some variation in trochoidal milling, and users need only high-speed spindles to take advantage of it.

Table 1. CAM software contains numerous productivity-boosting tools.

|

CAM software tool |

Benefit to user |

|

Dynamic milling |

Uses CAD model to automatically set optimal speeds and feeds. |

|

Create stock model |

Eliminates air cutting of castings and other preformed workpieces. |

|

Tooling libraries |

Allows well-organized management of tools and efficient cost/benefit analyses. |

|

Save to geometry |

Enables zooming in and making critical microadjustments to toolpaths in confined areas. |

|

Feature-based machining |

Evaluates a part’s features and automatically designs an effective machining strategy. |

Very low hanging—request CAD files instead of PDFs: Many shops I visit are racing to convert customer-supplied PDFs into CAD models to generate CNC machining and inspection programs. “Where do you suppose those PDFs came from?” I ask. The answer is mostly from AutoCAD, SolidWorks and ProE CAD files.

These shops can trim hours of engineering time from their quotes if they request that customers supply CAD files instead of PDFs. Most customers are more than willing to oblige when they understand the shop is saving time, reducing costs and eliminating data-entry errors that result in bad first-piece parts and model-based inspection results that look good but really aren’t.

Out of reach for some—3+2 machining: 5-axis machines give manufacturers the ability to perform advanced contouring work, putting them in the upper echelon of all shops. Job shops that can do 5-axis machining generally secure a higher level of work. If part families are also required, they will be in a position to capture the entire project—nobody likes to break up a family.

However, if a shop has access to only a little 5-axis work at the moment, how does it justify the investment in equipment, software and training? Here’s a surprise: It may not be that much of a reach. If you have the right equipment, such as a 3-axis, CNC vertical milling machine, a small investment in a trunnion table makes it possible to convert the machine to a 3+2 machining center. This allows 3-axis work that requires multiple setups to be done in one setup in many cases.

Further, the shop’s CNC programmers will be learning to deal with parts, tools and workholders in a 3-D space. If you want to get into contouring work, you will be halfway there. If not, you are still more productive.

Within reach for most—run machines faster: Any shop can immediately run their equipment faster by employing trochoidal toolpaths. These toolpaths make circular nibbling cuts around corners to cut faster and extend tool life. Almost all CAM software offers some variation in trochoidal milling, and users need only high-speed spindles to take advantage of it.

But that is just the beginning. Software vendors are continually introducing toolpaths, such as Mastercam’s Dynamic Mill and OptiRough, that run faster while reducing tool wear. Make learning what they are and how to use them a priority. [Editor’s note: see “Get with the Program” in the September 2012 issue for more information about Mastercam’s dynamic toolpaths.]

Quick picks—so many options: Your CAM software probably has many tools that could boost productivity if used properly. The trick to mastering them is avoiding the trap of trying to learn everything at once. Instead, choose one tool and use it for a week or two. Only move to the next one when you’ve got the first tool down. After a year, you will have mastered dozens of these productivity boosters. Table 1 on page 36 describes some of the available tools.

There for the taking—free consultation: Many software, tooling and machinery vendors provide their customers and prospects with a tremendous amount of support, such as free seminars and consultation services. Find some you feel comfortable working with and let them know you have a significant, high-volume project you would like to produce faster. See what each comes up with.

Plus, in the course of your discussions, they are likely to offer other low- hanging CNC fruit you could go after. Tuck these ideas away for future use after you have made progress in boosting productivity and can enjoy the fruits of your labor. CTE

Related Glossary Terms

- 3-D

3-D

Way of displaying real-world objects in a natural way by showing depth, height and width. This system uses the X, Y and Z axes.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- milling machine ( mill)2

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.