I have heard versions of this story repeated so many times it isn’t funny. There are two machine shops in the same market with similar equipment, software and customer bases. Shop A is struggling to get enough work and maintain healthy profit margins while being continually under the gun to meet difficult delivery schedules. There is never any time to investigate new manufacturing approaches and software that might improve this situation. The owner of shop A is convinced shop B is undercutting him with ridiculously low pricing that will ultimately cause both shops to suffer.

The owner of shop B would agree that CNC machining is a challenging business, to say the least. Part designs are becoming increasingly difficult to manufacture and the pressure is on to deliver small part runs on short notice. OEMs know that advanced CNC machining systems have reduced labor costs, and they are demanding part pricing that returns some of this savings to them.

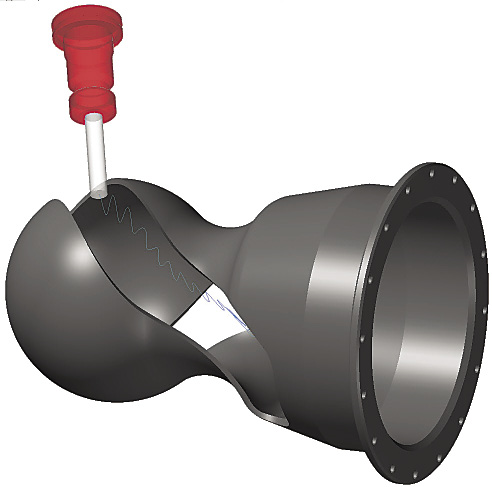

CAM software features, such as the 5-axis oscillating toolpath in Mastercam X7, can provide productivity gains. This toolpath significantly increases tool life and eliminates grooving by oscillating the tool to spread wear over a long user-definable section of the tool’s flute during a trimming operation.

Even under these difficult conditions, shop B has a growing stream of work and profit margins that allow it to invest time and money in new technology and training. This lets the shop out-machine the competition. Regarding “CAM initiatives,” shop B has them, and shop A does not.

CAM initiatives are on-going programs (large or small) advocated and driven by top management, who encourage shop personnel to take the time necessary to investigate how they can use equipment and software they already own or could easily acquire to do their work more efficiently. CAM initiatives are sometimes formal, including a written policy with specific goals and frequent reviews to make sure progress is being made and results are obtained. More often, CAM initiatives are simple, ad hoc efforts to solve a problem or do some frequently repeated task more efficiently.

When management smiles down upon CAM initiatives, shops can realize numerous benefits. The following are some ways to achieve them.

Educate everyone to their potential. I know a shop that finds a way to say yes to nearly every request employees make for additional training. It funds or partially funds e-courses, such as those conducted by Mastercam University, and course work that can be purchased in book form or electronically. The shop also encourages off-site training at local resellers and subsequent in-shop mentoring of those who couldn’t attend.

CAM is, after all, the lifeblood of a CNC machine shop. The person programming the machine tool not only uses it, but so do those who create manufacturing process documents, make fixture designs and do cost estimating. Machine operators who understand CAM software frequently make edits or even do a program overhaul even if they were not the originators of the NC program. Therefore, the more employees who are conversant with CAM, the better. Because CNC manufacturing talent is hard to come by, CAM initiatives help parts manufacturers grow their own.

Combat the curse of tool wear. Prematurely worn tools cost a shop a lot of money. They impede productivity by compelling frequent tool changes. They can hurt quality by making tool wear an impediment to achieving accuracy and finish. Software vendors are aware of this and have been making concerted efforts to reduce tool wear. For example, in the last few releases of Mastercam, dynamic toolpaths use higher speeds, minimal step-overs and full flute engagement to minimize wear.

In the latest version, Mastercam X7, a 3-D oscillating toolpath spreads the wear over a large tool area during trimming.

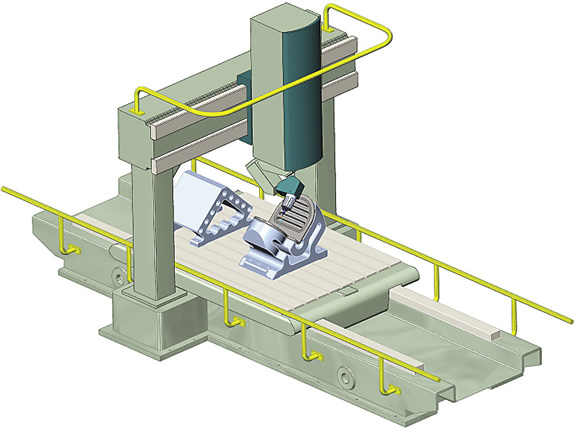

Run lights out. There are small “garage shops” that are nearly doubling their productivity by running CNC equipment at high speeds on a lights-out basis. This enables them to compete more effectively against larger shops. Unattended machining helps amortize the cost of sophisticated equipment over many more spindle hours per day. By using material-aware dynamic toolpaths with improved reliability features and incorporating in-process inspection with spindle probes and automated offset correction, shops can achieve unattended machining success rates that approach 100 percent.

As implemented in Mastercam X7, machine simulation allows multiaxis equipment to operate safely when unattended.

Embrace complexity. Many CAM initiatives look at ways advanced technologies can broaden the company’s market space. Most of the manufacturing jobs that have migrated overseas have involved simple parts that can be readily made using manual equipment in low-labor-cost countries. Becoming conversant with 5-axis and multitask CNC and CAM technology has allowed U.S. manufacturers to stay in the game by producing parts of increasing geometric complexity in a single setup. These same manufacturers translate their experience and knowledge base, as well as their manufacturing systems, to new markets when their traditional customer base, such as automotive, suffers a downturn. They are in a stronger position because their customers are diversified.

Fix what’s already working. “If it ain’t broke, don’t fix it” is an antiquated idea that costs many shops big dollars. There can be gold in refining manufacturing processes that were good enough just a couple of years ago but can be greatly improved by current CAM capabilities. Some machine shops have realized the enormity of this opportunity and turned some of their workers into process improvement specialists who develop highly efficient processes for existing and potential jobs.

Every CNC machining operation needs to encourage CAM initiatives so that they can make the most of their existing technology and software. Trustworthy CAM software resellers, of which there are many, are eager to work with machine shops to develop initiatives ensuring that CAM technology investments—money already spent—provide the highest possible payoff.

Because of their years of experience observing how things are done in many different shops, they are in a unique position to recommend equipment, best practices and innovations that can improve a business. A shop may have a specific improvement area in mind, but that is not always necessary. Simply ask the question: “What can we do to improve our productivity using our CAM system?” Chances are the answer will begin with, “Here’s a thought, what if we tried …” CTE

Related Glossary Terms

- 3-D

3-D

Way of displaying real-world objects in a natural way by showing depth, height and width. This system uses the X, Y and Z axes.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- in-process gaging ( in-process inspection)

in-process gaging ( in-process inspection)

Quality-control approach that monitors work in progress, rather than inspecting parts after the run has been completed. May be done manually on a spot-check basis but often involves automatic sensors that provide 100 percent inspection.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.