All images courtesy TDM Systems

Tool data management optimizes production resources and data.

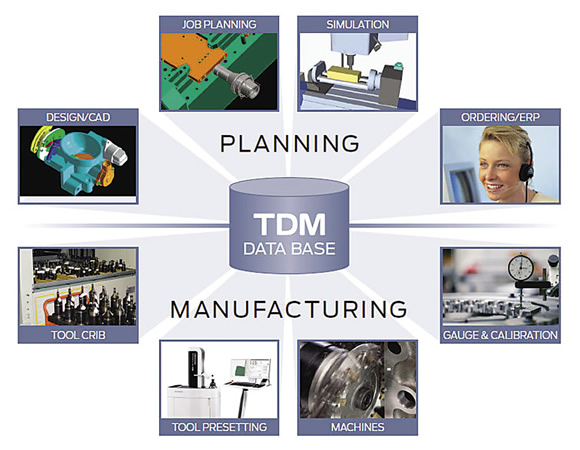

We live in a digital age, and tool data management (TDM) is part of the digital revolution in the metalworking industry. TDM software can enhance productivity, quality and profitability in a variety of ways, many of which are obvious and immediate and others, less obvious, are no less far reaching and profound.

For starters, TDM software provides rapid responses to some of the most basic questions in manufacturing: What tool assemblies, tool items and related equipment are needed for an operation and where are they located? That’s no small matter, because the number and variety of tools, tool items and setup equipment present manufacturing plants with significant, and frequently time-consuming, selection and assembly challenges.

Not only is the needed equipment located in different places, but the data resides in different locations as well. Tool and setup data may be in the machine tool controller, tool presetter, toolcrib or, generally, in all three locations. Lacking an integrated and transparent system, this data has to be reentered once or more during the manufacturing process, possibly from loose data sheets and tool lists stored in folders, sometimes with significant variances between the documents. Needless to say, this is a time-consuming procedure, one rife with possibilities for error.

Integrated Database

TDM software addresses these challenges and more. With a TDM base module, users can create an integrated and transparent central database of tools and production resources that gives them the ability to save tool or manufacturer catalog data in a unified format at the item level, including 2-D graphics and 3-D models. This information then travels with the tools throughout the production process to wherever it is needed. There is no longer any time-consuming searching for or inputting data or troublesome data discrepancies.

Further functions range from efficient tool provisioning and procurement (with each tool and tool assembly linked to inventory and enterprise resource planning systems and supplier and pricing information) to tool optimization calculations to production planning and NC programming. In addition, the system contains logic to easily generate tool assemblies. With just a few mouse clicks, the programmer can obtain the desired tool assemblies along with stored technical data for NC programing and simulation.

Accurate simulation requires high-quality digital data on tools, as well as auxiliary components and fixtures. By interfacing its central database of tools and production resources with the CAD/CAM system, TDM permits the rapid and accurate transfer of that data. This grows increasingly important as ever more complex processing requires realistic 3-D models to identify interference contours and ensure manufacturing reliability. Not only does process reliability increase with accurate simulation, but so does productivity, because the entire planning process is optimized and supported from the onset, saving significant time.

Avoid Customization

Users should opt for a TDM system that offers standard interfaces for a broad range of CAD/CAM systems. Similarly, modules that offer standard interfaces with leading enterprise resource planning (ERP) and manufacturing execution system (MES) protocols—as well as widely used tool presetting systems, tool cabinets and tool vending machines—optimize the value of the central tool and resource database that TDM provides.

A screen shot of TDM Systems’ software. When using tool data management software, users can keep tool data and graphics in a central location. As a result, current tool data is always used during planning and manufacturing.

TDM is thus able to function as a production data management system. Everything related to production data can be saved in the TDM database in an organized and transparent manner: tool items, tools, tool lists, measuring and inspection equipment, devices, technical data and machine data. If an operator needs to know which tools are used in which lists and NC programs, or which assembled tools are still in presetting or already connected to a machine, TDM will provide the information. It also provides data on which toolholders are available for a specific tool or which fixtures are available, including setting instructions and diagrams. Adding higher level interfaces to the mix, such as to MES and ERP systems, makes all of this data available to those systems in a comprehensive, accurate and timely manner. This optimizes planning processes, saving significant time and, thus, boosting productivity.

Purchasing, too, is optimized, allowing part manufacturers to ensure that precisely the right tooling and auxiliary equipment is in inventory when it is needed. Information on tool use history from TDM’s central database helps users order from suppliers with the best price and performance records. This information also helps users standardize their tooling, eliminating unneeded variety and duplication and reducing tool purchasing costs by as much as 25 percent.

The Power of Knowledge

Of course, tool use history is important for production as well. Knowing the amount of time a tool has been used is valuable. Often, though, that information is tracked and recorded in a haphazard manner—if at all. TDM permits users to quickly compare that information with the manufacturer’s recommended tool life. As a result, users can optimize tool utilization and improve part quality.

There is also the problem of legacy tooling. When a toolmaker decides to discontinue a tool in the user’s inventory, finding the right replacement is often a long, tedious process. With TDM, users can review the jobs a tool has been used on, then employ that information to identify suitable substitutes.

In manufacturing, knowledge is power, especially the knowledge the production staff has accumulated over time. TDM enables the production staff to record data that documents their experiences with individual tools and tool lists. In this way, an enormous pool of knowledge is created and made available to other production personnel, as well as to the planning staff, in a standardized and easily accessible format.

Ultimately, TDM software impacts an operation in many ways. Its broad functional scope ensures a reduction in machine-related downtime, decreased setup time and huge savings in data entry and programming time and expense. Uniform feeds and speeds for planning and production are always available in a comprehensive data pool, thus boosting part quality. Unifying processes provides transparency in the toolcrib, which reduces tool costs. And by providing an integrated and transparent production resource database, TDM makes production planning and purchasing more efficient and cost effective. It’s truly an investment worth considering. CTE

About the Author: Dan Speidel is sales director-USA for Tool Data Management Systems Inc., Schaumburg, Ill. For more information about the company’s software, call (847) 605-1269 or visit www.tdmsystems.com.

Related Glossary Terms

- 2-D

2-D

Way of displaying real-world objects on a flat surface, showing only height and width. This system uses only the X and Y axes.

- 3-D

3-D

Way of displaying real-world objects in a natural way by showing depth, height and width. This system uses the X, Y and Z axes.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.