The digital revolution has impacted everyone. The newspaper industry, for example, is slowly being replaced by information distributed on tablets and PCs. The cost of working in a paper-based environment is likely driving some of this change, but the cost savings involve more than simply eliminating paper. The data and intelligence that can be gained by going digital represents a far greater upside.

As is typical with a disruptive technology, expected cost savings drive initial adoption. But, over time, far greater impact is achieved once the new technology is better understood. For example, the Internet and e-mail have dramatically reduced the volume of mail carried by the U.S. Postal Service, threatening its entire business model.

The digital revolution has also impacted manufacturing. Information-driven, digital ecosystems drive manufacturing operations. While paperless adoption might have been initially implemented to achieve cost savings, now the speed and depth of knowledge acquisition from paperless operations is rapidly making it a must-have technology. This is because electronic information can be aggregated, cleansed, distributed and used more readily, accurately and effectively across a global enterprise than printed information. Ready access to knowledge improves decision making, customer satisfaction and operational performance.

However, paper is not necessarily the source of ineffective knowledge management or disbursement—other factors are also at play. The global economy moves at light speed, thanks to e-mail and other collaboration technologies. Organizations that can’t quickly adapt to this pace will have difficulty competing. They risk loss of industry leadership, market share and profitability.

Most manufacturers are aware of the broader paperless revolution and have successfully implemented some best practices. For example, use of the Internet for customer service and support is widespread, though not ubiquitous. The challenge companies confront is how to map a transition plan to a “pure” paperless environment without disrupting operations or breaking the bank. Companies must move beyond a few best practices and implement information technology strategies that allow them to compete in the “new” information-based economy.

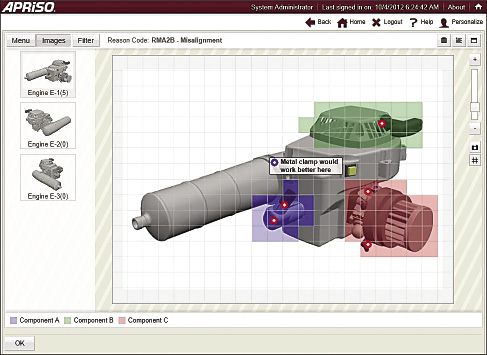

Courtesy of Apriso

Apriso for Paperless Manufacturing’s visual Quality Detect Tracking (vODT) feature enables digital annotation.

There are two general approaches to implementing a new IT strategy: a gradual transition or the “big bang” approach. Given the risk of disrupting operations, a staged transformation is often advisable, starting with a platform-based solution that can ease the journey. “True” paperless operations require more than automated data capture. Information must be instantly distributed and readily available across the decision network.

This type of information access entails direct, real-time data sharing between functions, departments and locations to avoid additional handling and the reentry of data. This type of information strategy cannot be effectively implemented as an add-on to legacy applications or systems designed for a paper-based environment. Users need a “native” paperless platform to capture all the potential benefits without suffering a loss in productivity or effectiveness.

Apriso for Paperless Manufacturing is an example of this kind of platform-based solution. It can be used to implement anything from a basic paperless offering—electronic work instructions and reports that enhance intraplant communications—to a complete enterprise solution that covers paperless production, warehouse, quality, maintenance and labor activities. With this solution, a manufacturer can improve control of its work instructions, engineering changes, quality characteristics, components, resources and safety procedures.

Beyond simply eliminating paper, there are significant cost savings and performance improvements that may not be initially apparent. Similar to other technology disruptions, the potential benefits to manufacturers when leveraging a platform-based paperless solution are substantial, including:

- Improved quality. With constant control and monitoring, errors are identified and corrections introduced earlier, reducing production defects and raising overall product quality. This can be accomplished at a low cost with minimal waste.

- Reduced time-to-market. By eliminating time-consuming, paper-based manual activities, new product introduction can be accelerated while simplifying engineering change management. This approach helps to ensure the most current design is used in production to avoid recalls, ultimately improving customer satisfaction.

- Increased innovation. By reducing the change-related administrative workload, manufacturers have more time to develop innovative products and processes. Simply stated, if you were to see a minor improvement but faced a mountain of paperwork to push it through, would you suggest the change? Not likely. In a paperless world where change is embraced and easily accommodated, design and execution improvements can be more readily made. Moreover, continuous improvement can be boosted by analytics possible with digital data.

- Improved performance. By allowing employees to focus on executing processes as directed—with seamless integration and access to the latest design processes—individual performance can be improved. This productivity improvement complements the previously mentioned innovation concept—making changes and improvements much easier to accomplish.

- Automated adherence to compliance and traceability. An electronic process provides automated tracking and linking, thereby ensuring better audit results and greater accuracy when managing product recalls or meeting traceability requirements. Having a complete record of all components, resources, processes characteristics and executed operations not only certifies regulatory compliance, but also helps reduce warranty claims and limit the need for product recalls.

Access to timely, accurate data is critical to the effective implementation of best manufacturing practices. Continuous process improvement plays a key role in achieving and sustaining competitive viability. For global enterprises, a paperless approach is important to establishing an aggregated perspective on operations visibility—from both the plant’s and the headquarters’ perspectives. It is also an essential part of an efficient change-control process that allows companies to compete while complying with government regulations.

Now is the time to prepare a paperless strategy and map your path to success. With the option to “crawl, walk and then run,” much of the risk of implementation can be mitigated. Quick and increasing cost savings can fuel a program through to completion. It’s critical to evaluate what stage your company is at compared to the competition. Can you afford to let your competitors benefit from paperless operations while you are left behind? CTE

Related Glossary Terms

- payload ( workload)

payload ( workload)

Maximum load that the robot can handle safely.