True or false: Measuring parts and collecting data, unlike other processes, are not subject to variations.

This statement is, of course, false. Variation is inherent to any system, and the measurement and data-collection processes are no exception.

All images courtesy PQ Systems

A digital caliper and a digital micrometer.

A perfect measurement system does not exist; every system introduces some amount of variation. An excessive amount of variation in the measurement system may lead to false signals on control charts and untrustworthy recorded measurements that render the process of analyzing data with statistical-process-control tools futile.

Quality managers strive to reduce or limit variation in their measurement systems. In addition to using operational definitions to ensure measurement consistency, companies should periodically perform repeatability and reproducibility (R&R) studies on their gages and regularly recalibrate them.

Most part manufacturers understand the importance of regular calibration to ensure their gages and other measurement devices are within acceptable tolerances. But while calibration assesses the accuracy of the measurement device, it doesn’t guarantee overall measurement accuracy. Outside influences that affect measurement systems are always present. For example, even an extremely precise and accurate gage, if used by a poorly trained operator, may generate faulty results.

The Two ‘Rs’

A comprehensive plan to reduce measurement variation includes conducting gage R&R studies. While calibration assesses only gage accuracy, a GR&R study can identify many areas of variation. Most notably, a completed study will yield a breakdown of the contributing sources of equipment and appraiser variation. These two elements, combined, yield an R&R percentage.

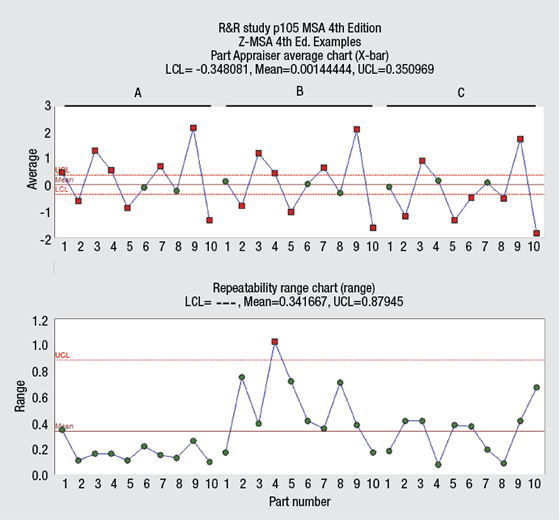

The first R, repeatability, reflects measurement error when all factors are kept constant: the same appraiser, gage, measurement procedure, and part or sample. This part of the study determines what variation can be attributed to the equipment. Reproducibility, the second R, compares the measurements of all appraisers (typically the same technicians that use the gages) to determine if there is a significant amount of variation among them.

Regularly scheduled GR&R studies can be incorporated into an organization’s quality system. The first study can serve as a baseline to determine how well the measurement system is performing. With the initial study recorded, quality managers can then investigate the main sources of variation. With that knowledge, they can take appropriate steps to correct and reduce measurement system variation.

GR&R studies usually open a dialog between the gage users and their supervisors. This discussion can lead to improved measurement procedures and even operator retraining, if necessary.

Besides the measurement systems, variations can arise because of the workplace. Common sources include the workpiece material, gage, manpower, production methods and the manufacturing environment. The workpiece material being measured, for example, can expand over the course of normal production and affect the measurements taken. The accuracy of the gage is obviously critical, as are the measuring methods used and the people taking the measurements.

The manufacturing environment is an often-overlooked factor. Temperature and humidity where the measurements are taken can influence study results, sometimes in dramatic ways. Other environmental factors include excessive dust, vibration and magnetic fields.

Careful Calculations

Preparation is critical to the validity of a GR&R study. It can be easy to head down the wrong path at the onset and become bewildered by confusing data at the end of the process. And, a study can take a long time. Some studies may begin weeks before the first measurement is taken.

A random selection of parts must be gathered ahead of time. It’s important to have a good spread of the natural process variation. Simply grabbing the last 10 parts off the production line could lead to a poor R&R percentage because of how the results are calculated.

Sample of a part appraiser chart (top) and a repeatability range chart.

When conducting a GR&R study, users of the gage being studied should also be the appraisers. Parts should be measured in a random order, and the results should be concealed from the appraisers to prevent one appraiser from influencing another’s measurements. Also, the environment where the GR&R study is conducted should be the same as where measurements are normally taken, or as close to it as possible so as to avoid introducing new elements of variation.

After measurements have been gathered, calculations can be performed using one of several approaches, such as the measurement system analysis (MSA) method from the Automotive Industry Action Group, the ANOVA (analysis of variance) method or the EMP III (evaluating the measurement process) method.

As mentioned earlier, all the calculations yield an R&R percentage, but each can provide additional details about the source of variation in the measurement system. After finding a method that works well and meets auditing requirements, it is important to use the same one for subsequent GR&R studies.

No matter which calculation method an organization employs, software can streamline the calculation process. GR&R studies are like forms to be filled out, which means the data can be calculated automatically. This is a better method than performing calculations manually, which is not only time consuming but also increases the risk of error. Calculating at least one study by hand helps you understand how the results are computed, but, after that, let a program churn out the results. Numerous software programs are available.

GR&R studies improve understanding of measurement systems. They can identify sources of variation that might otherwise not have been discovered. With study results in hand, quality managers can improve manufacturing and measurement procedures, thus reducing unwanted variation. The goal is to have as little measurement variation as possible so gage users react only to actual process variation. CTE

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.

- micrometer

micrometer

A precision instrument with a spindle moved by a finely threaded screw that is used for measuring thickness and short lengths.