CHALLENGE: Upgrade QC to reduce the amount of time required for dimension measurements.

SOLUTION: Utilize an image-dimension-measuring system that enables hundreds of features to be measured in seconds.

END USER: Autocam Corp. Inc., (800) 747-6978, www.autocam.com.

SOLUTION PROVIDER: Keyence Corp. of America, (888) 539-3623, www.keyence.com.

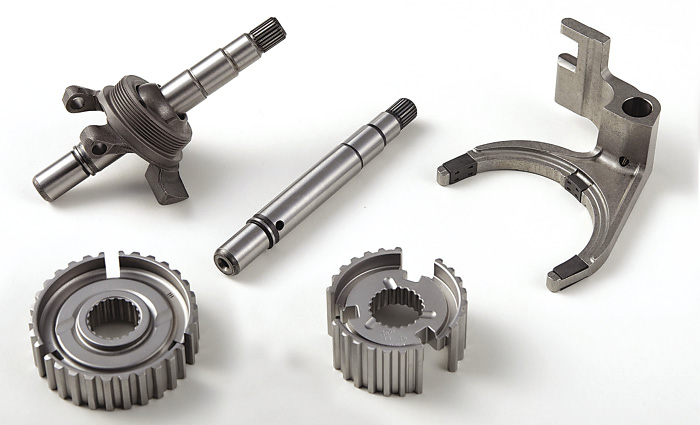

Autocam Corp. Inc., Marshall, Mich., specializes in producing components for emerging fuel technologies in the automotive industry. These parts require in-process measurement because they play a critical role in transportation safety. In the past, the company utilized five different mechanical hard gages and five different inspectors, resulting in slow measuring speeds and high costs.

To improve in-process measurements, Autocam’s Precision Components Group purchased an image-dimension-measuring system from Keyence Corp. of America, Itasca, Ill., for its QC measurements.

A dedicated CMM programmer is not required for the image-dimension-measuring system from Keyence. Once a program is created, a user loads a part and presses a button. Image courtesy Keyence.

The system from Keyence’s IM series incorporates a specially designed lens to provide a wide field of view. Coupled with an auto-focus capability, the measuring device reportedly ensures that the part is always in focus while a telecentric lens maintains a constant image size regardless of height differences on the target. This allows the accurate measurement of parts with uneven surfaces.

The system automatically adjusts the lighting, focus and program to match each part on the stage. It recognizes the profile and reflective images of each part, compares it to preprogrammed tolerances, indicates “pass” or “fail” for each dimension, and saves the data locally or to a network. With the push of a single button, it prints a full inspection report in 3 seconds.

“With the Keyence IM, we can perform the checks of all five gages with one inspector at more than twice the speed,” said Spencer DePew, quality/gage technician at Autocam.

The IM series has 24 internal lenses, four of which are large telecentric lenses that provide a 4" (101.6mm) field of view. Telecentricity is desirable for inspection systems, as it provides constant magnification (object size does not change) over a range of working distances. This virtually eliminates perspective-angle errors and means that object movement does not affect image magnification, which provides highly accurate measurements.

The system is portable, because of its specially designed lens housing, allowing for transport from location to location without the need for recalibration or the use of a granite slab. And DePew pointed out, the user interface is easy to understand. Once a program is created, the operator just has to load a part and press a button, he said. The programming does require some training from Keyence, but DePew noted it’s not too difficult, “especially for those with a metrology background.”

Because of the critical role that Autocam parts play in transportation safety, inspection and measurement systems are used throughout the production floor to perform in-process quality inspection. Image courtesy Autocam.

A challenge in using the IM system, according to DePew, was false positives due to an imperfect part washing process. “We had issues with false rejects due to rust-preventative buildup from our washing process. We had to alter our process to accommodate.”

He added that the correlation between mechanical hard gaging can be tricky. “The IM has more flexibility in how you can measure a part feature, and, so, to correlate, you have to try and mimic how and where the mechanical hard gages measure.”

The IM system has improved quality by reducing damage from hard gaging. “Operators can get quick feedback on their quality checks, which prevents unnecessary scrap due to waiting on a slower measurement system,” DePew said. “The IM has given Autocam the ability to add additional quality checks, as needed, in a short amount of time without adding additional gaging or cost.”

Related Glossary Terms

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.