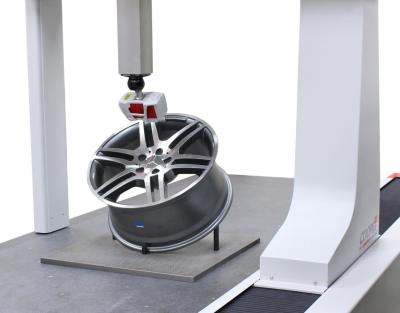

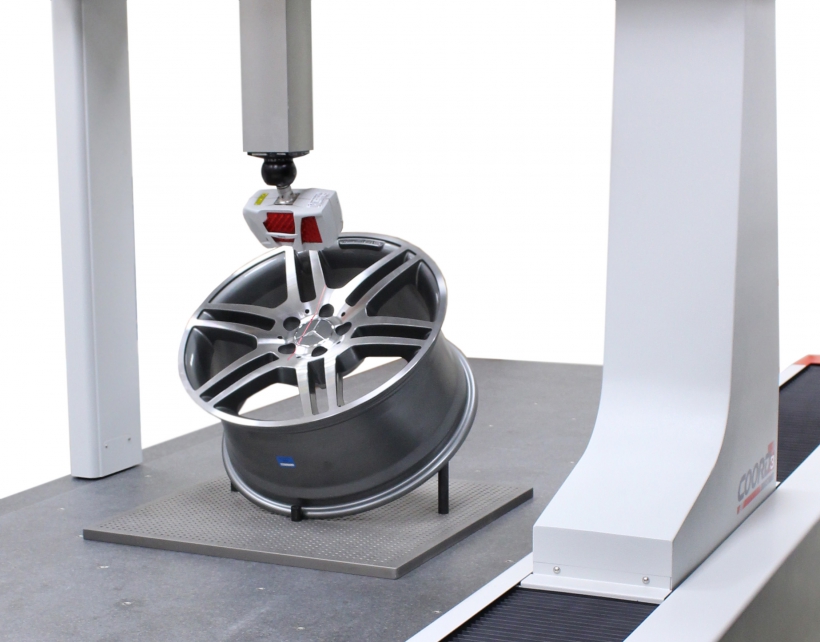

Perceptron Inc., Plymouth, Mich., recently launched the Expert Coordinate Measuring Machine, a CNC multi-sensor system that seamlessly integrates touch-probe and laser scanning functionality into a single measuring station, according to a company news release issued Feb. 8.

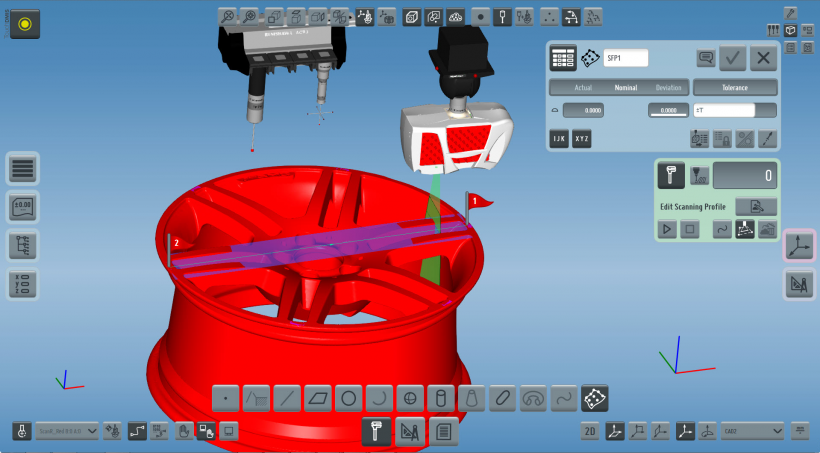

Operated exclusively by touch software, the Perceptron Expert CMM reportedly offers full point-cloud geometric feature extraction and direct comparison to CAD for automated inspection of production parts. The company added that the automatic scanning package is said to be priced comparable to lower accuracy manual portable arm measuring solutions.

Operated exclusively by touch software, the Perceptron Expert CMM reportedly offers full point-cloud geometric feature extraction and direct comparison to CAD for automated inspection of production parts. The company added that the automatic scanning package is said to be priced comparable to lower accuracy manual portable arm measuring solutions.

The Expert CMM reportedly builds on Perceptron's expertise in automated inline production metrology for global vehicle production by widening the reach of its industry-leading scanning technology for general manufacturing, according to the news release.

Perceptron’s TouchCloud™ software module add-on for its TouchDMIS™ software puts the Expert CMM into the solution, and significantly reduces the necessary user skill level, the company explained. Full feature extraction from point-cloud is said to provide for faster and more accurate measurements. Part features also can be touch-probed or laser-scanned, depending on feature type and tolerance.

The Expert CMM can be supplied with any size and configuration CMM from the Perceptron Coord3 CMM range, or retrofitted to existing customer-installed CMMs, the company added.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.