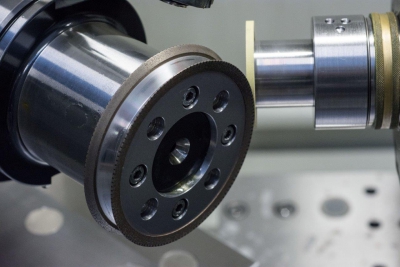

Meister Abrasives USA, Inc. has introduced a new generation of cDD Diamond Dressers that deliver certified tool radius tolerances, which are essential for most demanding microprecision grinding applications. The radius form tolerance of these new microprecision diamond dressers can be certified accurate to within 2μm (+/-0.001mm) if the application requires.

Bruce Northrup, vice president and general manager of Meister Abrasives USA said, “To dress grinding wheels for ultrahigh precision applications the user needs to have a precise, certified radius value to plug into his CNC dressing program. Very few dressing wheel manufacturers have been able to achieve this degree of certified precision. Meister’s introduction of microprecision certified cDD dressers is the result of a multiyear R&D project which culminated in a major investment in manufacturing, measurement and verification systems. These have enabled Meister Abrasives to achieve an order of magnitude improvement in the accuracy and precision for these unique dressers.”

This degree of certified precision makes microprecision cDD Diamond Dressers suitable for the CNC truing and sharpening of grinding wheels used in manufacturing automotive and aerospace bearing races, high-precision gear grinding, plunge grinding of fuel injection armatures and needles, and other critical grinding applications that require form tolerances as tight as 2 microns.

These cDD dressing tools rely on a unique structure in which high quality CVD diamond inserts are strategically embedded within Meister’s hDD porous hybrid-bond matrix.

Contact Details

Related Glossary Terms

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- dressing

dressing

Removal of undesirable materials from “loaded” grinding wheels using a single- or multi-point diamond or other tool. The process also exposes unused, sharp abrasive points. See loading; truing.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- truing

truing

Using a diamond or other dressing tool to ensure that a grinding wheel is round and concentric and will not vibrate at required speeds. Weights also are used to balance the wheel. Also performed to impart a contour to the wheel’s face. See dressing.