Autodesk is ushering in its new 2017 CAM products for a multitude of advanced manufacturing applications ranging from CNC mill- and lathe-programming to complex mold and die manufacturing. These new products combine the heritage of industry leadership in CAM software from Delcam with Autodesk’s 3D design and manufacturing prowess, presenting Autodesk CAM customers with a powerful and unique user experience, according to the company.

Autodesk’s 2017 CAM products include enhanced versions of FeatureCAM for automating CNC programming; PartMaker for precision part manufacturing with Swiss-type lathes; PowerMill for designing the most complex molds, dies and other components; PowerShape for the design of 3D complex parts; and PowerInspect hardware-independent inspection software. New capabilities for each of the 2017 CAM products are detailed below.

“Manufacturers need to iterate and innovate faster than ever before to stay competitive as the marketplace is redefined by a new future of making things,” said Mark Forth, manager of manufacturing industry strategy at Autodesk. “Autodesk’s new 2017 CAM products are designed to help our customers learn, improve and master advanced manufacturing techniques that ultimately lead to better designed and functional products being brought to market more quickly and efficiently.”

Autodesk FeatureCAM is an easy-to-use solution for milling machines, turning and turn/mill centers, and wire EDMs. The automation tools within FeatureCAM help manufacturers reduce programming time, allowing parts to be made faster. They also increase programming consistency for maintaining part quality. The 2017 version of the product includes the following improvements:

- New programming capabilities for dual-path Swiss-type lathes, further improving its range of CNC machine support

- Ability to import and view product and manufacturing information directly from a model in order to help visualize design specifications

- Access to functionality that allows pre-drilling when using Vortex toolpaths, ruling out the need for helical ramp moves

In addition to the features above, PartMaker 2017, which enables complex, high-precision part manufacturing with Swiss-type lathes, is available within the FeatureCAM 2017 Ultimate product tier. The two products in combination form a complementary bundle that effectively addresses the programming requirements of today’s manufacturing shops.

“We have a great history working with FeatureCAM, and when we were asked to evaluate the new Swiss lathe functionality, it was a no-brainer for us,” said Bill Karas of Karas Kustoms. “In the past, I had been programming the Swiss machine by hand. Using FeatureCAM for the Swiss machines saves our company a ton of time with excellent results.”

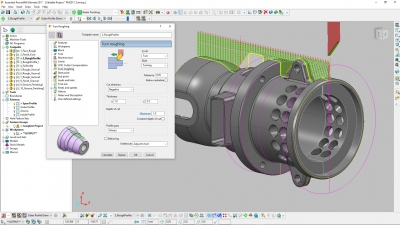

Autodesk PowerMill 2017 takes the ability to easily and effectively manufacture the most complex molds, dies and other components to new heights. This latest version includes the following new features:

- More efficient 3D offset finishing toolpaths, greater simulation controls and constraint-based logic to optimize non-cutting link moves for safer, more efficient machining

- For the first time, PowerMill also provides strategies to create turning routines for use on 5-axis mill-turn machines

These improvements continue to reportedly make PowerMill the ideal choice for manufacturers looking to solve the most demanding of 3-axis, high-speed and complex multi-axis applications.

“PowerMill helps us to maintain a high level of consistency in our programming, which directly and positively affects time in process and customer satisfaction,” said Randy Lee Meissner, CNC department supervisor at Dynamic Tool and Design. “We develop processes where each engineer is using the same techniques and the same tools, so there is no variation among the work everyone is doing. In the old days, there may have been some hand-fitting, but today we can count on uniformity in the molds we create from order to order.”

The design of 3D complex parts just became more effective with the following improvements to PowerShape 2017:

- Accessibility shading to identify areas of a part that cannot be machined with 3-axis machining alone

- A new rib capping tool allows users of EDM technology to automatically create surfaces in order to stop cutting tools from machining slots that will be produced by EDM. Hundreds of surfaces are created in a single command, saving hours of manual modeling.

- The PowerShape electrode wizard offers improved EDM hardware integration for shop-floor burning

- Finally, regular users of reverse engineering tools can benefit from improved fitting of surfaces to imported triangle meshes

Autodesk PowerInspect simplifies the inspection of complex shapes by providing a single solution for a range of measuring equipment. PowerInspect 2017 includes the following new features:

- Support for portable measuring equipment, coordinate measuring machines (CMMs) and On Machine Verification (OMV) are offered in a single package for PowerInspect Ultimate users. This improves productivity and flexibility by making it easier for operators to select the most appropriate measuring equipment for each job.

- The ViewCube feature offers specific benefits for visualizing inspection results and creating inspection reports

- A single click mechanism to recall the principal CAD viewpoints, making the creation of consistent inspection report images faster and easier than ever before

- Improvements to point-cloud performance now allows users to take advantage of the improved capabilities in the latest scanning equipment

- A dedicated point-cloud single point item provides an easy way to evaluate target points from laser scan data

Contact Details

Related Glossary Terms

- burning

burning

Rotary tool that removes hard or soft materials similar to a rotary file. A bur’s teeth, or flutes, have a negative rake.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.